How to Insert Miniature Small Boats into Bottles

For those who do not know .. sometimes we are confused how can a small boat can be in a bottle? this question that we often say when we see the unique objects of human hands.

but you do not need to be confused now, because we will discuss How to Make a Ship In Bottle ..

if we think for a moment The ship is clearly much larger than the surface of the mouthpiece in the bottle. Many people think the bottom of the bottle is cut? however our perception of the small vessel is made of wood, paper screens and threads.

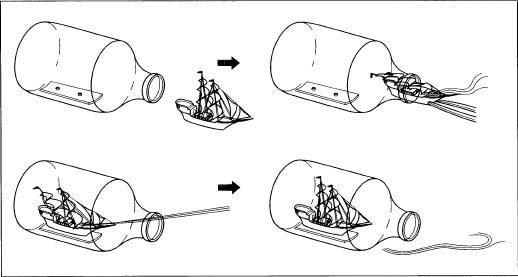

The secret is that the hull of the vessel is small enough to enter through the neck of the bottle, but the screens and spars (poles and sailing supports) are folded and can be pulled into a position using the control thread.

Wood for the hull and glass bottle should be chosen according to the model and where the bottle will be placed or displayed on the shelves or tables with ease, the measurement of the parts of the vessel is controlled by the inner diameter of the bottle neck. Typically, wood is hardwood like pine or spruce, and should be near-grained without flaws.

Other wood supplies include bamboo skewers of small diameter pens for spars, popsicle sticks that can be carved deckhouses and lifeboats, wooden hulls suitable for standing screens, and larger blocks of wood pieces for standing work are raised. Sandpaper in the class from about 120-200 to smooth the stomach and other wood is also important.

Yarn, wire, glue, and clear nail polish are used for rigging, metal trims such as rails, and pieces attached together (nail polish is also used as glue). Beeswax helps to close the lumps of the thread together. Tiner paint, enamel models in various colors, and fine brushes are materials and tools for painting parts of the ship. Medium-weight white bond paper is cut into shapes from the screen, and stitches are picked on with a pencil that is also used for the screen curve.

This hobby also requires the selection of simple tools such as an exacto knife, a hobby drill with fine bits, and a miniature screwdriver, a saw, and a scratch. Some tools should be made for specific size bottles and models. These include wire tweezers, spoons, and tampers to reach the back of the bottle and to scoop and tamping putty or clay into place. Cloth hangers can be cut and shaped into a long handle for this tool, and pieces cut from tin can be soldered to the cable to complete this Design

following the procedure

When the vessel and bottle have been selected, this is the core of how the boat can enter the bottle all the measurements from both must be checked. Ship bodies and sleeping poles should fit through the bottle neck and should not hit the top or side of the bottle when the poles are to be erected

The ship's construction begins with a stomach engraving. The wooden block should be gripped in the vise until the base shapes, curved sides, and deck are cut. Sculpt out the extra wood that makes the deck lifting section around the edge of the deck. The bow and rod (front and rear ends) of the ship are formed next, and the hull is cut from the host block of the wood. The stomach should be sanded with a finer sandpaper and coated with clear nail polish that will cover the wood and "varnish" deck. The outer hull is then painted with two layers of true color enamel. The thread used to mark a straight line indicates the port of the gun and other lines.

thank you hopefully useful and add our insight into how the ship can enter into a bottle so small. thank you and see you friends @rizkart