This Revolutionary Thing Could Replace The Traditional Concrete

What if you could construct a home or apartment building that is not just fire-resistant like concrete, but also more energy-efficient and environmentally friendly than traditional structures?

Let's look into hemp construction materials and their advantages in terms of attaining a low-carbon future. Could hemp bricks be a viable alternative to concrete?

Sustainable homes, together with renewable energy and electric vehicles, are critical for bringing our world closer to a net-zero future. Residential homes and flats account for around 21% of worldwide carbon emissions, with heating and cooling accounting for a large portion of it. However, traditional construction materials such as concrete and metals, as well as the manufacturing and construction process, produce carbon emissions and waste.

Concrete is the most widely used building material in the world, accounting for around 8% of global CO2 emissions. Steel is responsible for an additional 11% of worldwide carbon emissions.

Natural and eco-friendly building materials are being developed to produce more sustainable homes and plot a route to a net-zero future. Straw bales rammed earth, recycled plastic, bamboo, and mycelium are just a few examples.

There's a new eco-building material that's gaining popularity all around the world. Hemp could be the next eco-building material due to its resilience, insulating characteristics, fire resistance, low carbon footprint, and lower density!

When someone mentions hemp, your mind may immediately go to marijuana. Hemp is a type of Cannabis Sativa that contains only a little amount of THC, the intoxicating ingredient. I'm sure some of you know what I'm talking about. Marijuana flowers typically contain 15% THC, but when extracted, that percentage can reach up to 90%. Hemp, on the other hand, has only approximately 0.3 per cent. It's a versatile substance that may be used to make garments, oilseeds, ropes, and food, among other things.

Its backstory use

Hemp has been harvested for thousands of years, with evidence of its use dating back to Asia around the year 8000 BC. Europeans utilized hemp to build ropes around 600-200 BC. By 100 BC, the Chinese had begun to use the plant to create paper. Americans recognized the benefits of hemp for food, ropes, shoes, and clothing in the 1600s.

So what hempcrete is and how it's building up…

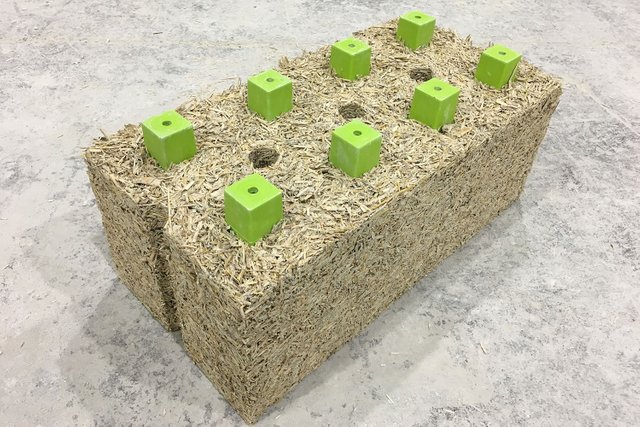

Hempcrete is a composite produced from water, lime, and the inner core of hemp stalks. The lime component is made up of air lime, which helps the setting process go faster.

This combination produces a robust, biodegradable insulator that is flame-resistant, pest-resistant, moisture-balancing, and flame-resistant. Hempcrete can also be ground and rehydrated, making it reusable.

Hempcrete may be used to build self-insulating walls, roofs, and screeds, and it can be used for new construction as well as renovations. When creating walls, hempcrete is typically cast around a structural frame composed of wood, metal, or concrete.

While these are useful features, when it comes to building a sustainable home, one of the most important factors to consider is the insulation value, or how difficult it is for heat to travel through. Hemp takes a dominating lead in this area. Hempcrete-built homes have exceptional thermal performance. Hempcrete's value ranges from 0.06 to 0.07 W/mK (Watts per meter-Kelvin), while concrete's range from 0.62 to 3.3 W/mK (Watts per meter-Kelvin). The lower the value, the better for keeping a house warmer in the winter and cooler in the summer.

You may be more familiar with the term R-value, which refers to a material's resistance to heat conduction; the higher the R-value, the better the insulating effectiveness. For example, the R-value of concrete used in floor slabs ranges from 0.1 to 0.2 per inch of thickness, thus a 6-inch thick slab would have an R-value of 0.6 to 1.2. Hempcrete, on the other hand, has an R-value of 2.4 to 4.8 per inch, so that same 6-inch slab would have an R-value of 14.4 to 28.8. That's a significant difference, implying that hempcrete will save money on a building's energy bill and maintenance expenditures during its lifetime.

For a quick, cost comparison, concrete is less expensive than hempcrete, costing $85 per square meter versus $135 per square meter on average. Hempcrete, on the other hand, can save up to 80% of energy, mostly in the areas of heating and cooling.

A 170m² residence built by DB Chanvre with hempcrete and a wood frame system, as well as an insulating wall, ground floor slab, and first-floor screed, had a heating bill of €300 (about $340) for six to seven months of heating, which can vary depending on the year. A similar-sized house's heating bill would be around $1,055.

Both concrete and hempcrete collect CO2 during their lives, which is a significant factor to consider. They're both carbon sponges, but concrete's benefits don't outweigh its drawbacks. According to an Intergovernmental Panel on Climate Change (IPCC) report, each tonne of concrete produced in 2018 released between 0.5 and 0.6 tonnes of CO2, yet concrete absorbs around half of that CO2 over its lifetime. Hemp, on the other hand, is carbon-negative, meaning it absorbs more CO2 from the environment than it emits during cultivation. Industrial hemp can remove 15 tonnes of CO2 from the environment every hectare.

And, depending on the weather, the lifespan of hemp as a building material can be hundreds of years. A hemp home built in 1698 more than 300 years ago is classified as a national cultural landmark in Japan, for example.

In terms of strength and affordability, how does hempcrete compare to concrete? When properly cured, concrete is non-toxic, fire-resistant, pest-resistant, may last for thousands of years, and is more resistant to standing water than hempcrete. Hempcrete, on the other hand, can hold more than 1,300 pounds of water vapour without degrading, making it ideal for high-humidity environments. When it rains, it may absorb the water and release it when the sun returns, protecting the building from moisture and preventing it from splitting over time, as concrete does.

Concrete may readily acquire compressive strengths ranging from 3,000 psi to 4,000 psi when it comes to compressive strength, which is basically a material's resistance to crushing before breaking. Hempcrete, on the other hand, reaches substantially lower pressures, ranging from 72.5 to 507.6 psi, however, this can be compensated for by additional supporting frameworks. Compressive strength, on the other hand, isn't the only metric of strength. During an earthquake, when shear loading (trying to tear) becomes more critical, hempcrete is three times more resistant to cracking than conventional concrete.

Hempcrete is extremely lightweight and has good insulating properties, but it isn't strong enough to create a load-bearing wall on its own. Hempcrete cannot be used to construct a house's foundation on its own. In addition to standard plumbing and electrical supplies, materials like wood or steel must still be used to construct the fundamental framework.

Concrete wall prices vary depending on thickness and region, but according to Home Advisor, the cost per square foot ranges from $10 to $60. Despite these benefits, there are a few obstacles to overcome before it becomes a widespread sustainable building material. Hemp fibres are ready to harvest in two months on average, but there is also a curing phase, so it is not as readily available as concrete. There are also few builders with hands-on experience with hempcrete in the construction of homes, as well as a paucity of information and education about it.

The global industrial hemp market was worth $3.61 billion in 2020, and it is predicted to increase at a 16.2 per cent annual rate from 2021 to 2028. Although hempcrete cannot completely replace concrete in all applications, there are some advantages to employing hemp in the construction of environmentally friendly dwellings. It can help households live in a healthier atmosphere, save money on heating and cooling, and contribute to a more sustainable society. Although utilising hempcrete and hemp insulation to create a home is now more expensive than using concrete and other materials, the energy savings from the excellent insulation values can balance the initial expense. Furthermore, as more businesses enter the market, prices should fall in the coming years.

Hempcrete materials may not be the magic bullet that will eliminate our need for concrete, but they are a capable product that can be used in a variety of applications.

What are your thoughts on hemp being used in construction like this?