Comparing Custom Heatsink Manufacturer Solutions for Specific Industry Requirements

As electronic devices become more advanced and compact, thermal management challenges intensify, making custom heat sinks essential for many industries. A custom heatsink manufacturer can tailor cooling solutions to meet the specific needs of various sectors, from automotive to telecommunications, where standard off-the-shelf heat sinks may fall short. Here’s a closer look at how custom heat sink solutions compare across different industries and why it's important to select the right manufacturer for your specific application.

Automotive Industry

In the automotive industry, the demand for reliable and efficient cooling solutions has grown alongside the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). Components such as power electronics, inverters, and battery systems generate significant heat that requires precise management to ensure long-term performance and safety.

Custom heat sink solutions in the automotive sector often prioritize ruggedness, compact size, and high thermal conductivity. Custom heatsink manufacturers for this industry need to provide solutions that can withstand harsh conditions such as extreme temperatures, vibrations, and humidity. In some cases, heat sinks may be integrated with liquid cooling systems to enhance performance in high-power applications. The best manufacturers will offer advanced materials and designs, like bonded-fin heat sinks or heat pipes, to ensure that heat dissipation is both rapid and reliable in such demanding environments.

Telecommunications Industry

Telecommunications equipment, including servers, routers, and base stations, operates continuously and generates substantial heat. Maintaining stable temperatures in these systems is critical to avoid downtime and ensure consistent performance. In the telecommunications sector, heat sinks need to be highly efficient and capable of cooling densely packed electronic components.

Custom heatsink manufacturer solutions for telecommunications often focus on maximizing heat dissipation in confined spaces. Manufacturers must be able to design compact and lightweight heat sinks, such as extruded or folded-fin designs, that allow for effective airflow and cooling without compromising on the equipment's space constraints. Passive heat sinks, combined with active cooling like fans, are commonly used to enhance cooling performance.

Additionally, reliability is crucial in this industry, as telecommunications equipment often functions in remote or difficult-to-access locations. A custom heat sink that fails to perform effectively can lead to expensive maintenance or replacement, making durability and long-term performance key considerations when comparing manufacturers.

Medical Devices

In medical technology, precision, reliability, and safety are paramount. Medical devices such as imaging systems, diagnostic machines, and surgical instruments often require precise thermal management to ensure that they operate accurately and consistently. Overheating in such devices can lead to measurement errors, equipment malfunction, or even risk to patient safety.

Custom heat sinks in the medical field must meet strict regulatory standards and deliver highly efficient thermal management in compact designs. Custom heatsink manufacturers for this industry must offer solutions that ensure low-noise operation (especially in sensitive medical environments) and reliability during continuous operation. Manufacturers also need to accommodate the unique materials and sterilization requirements necessary for medical-grade equipment. Depending on the device, heat sinks may require advanced coatings or surface treatments to prevent corrosion and ensure long-lasting performance.

Consumer Electronics

In consumer electronics, such as smartphones, laptops, and gaming consoles, cooling efficiency and form factor are major considerations. Devices are becoming smaller and more powerful, generating more heat in increasingly confined spaces. A custom heat sink solution is often needed to handle the specific power and thermal demands of these devices without affecting their performance or aesthetics.

Custom heatsink manufacturers serving the consumer electronics sector must be able to create innovative solutions that optimize heat dissipation while minimizing size and weight. Techniques such as vapor chambers, micro-channel heat sinks, and heat pipes are frequently used in these applications to achieve the required cooling efficiency. Additionally, these heat sinks often need to be integrated seamlessly into the product's design, making customization critical for both performance and visual appeal.

Industrial Equipment

Industrial equipment, such as power supplies, motor drives, and control systems, often operates in challenging environments where heat dissipation is critical for maintaining operational stability. These systems typically have high-power components that generate significant heat, requiring robust and durable heat sink solutions.

Custom heatsink manufacturers serving the industrial sector focus on providing heat sinks that can withstand high temperatures, dust, and potential exposure to corrosive substances. They must also design solutions that can handle continuous operation, often in high-stress conditions, without failure. Materials like copper and high-grade aluminum, along with advanced manufacturing processes like die-casting or vacuum brazing, are frequently used to achieve durable, high-performance heat sinks for industrial applications.

Data Centers

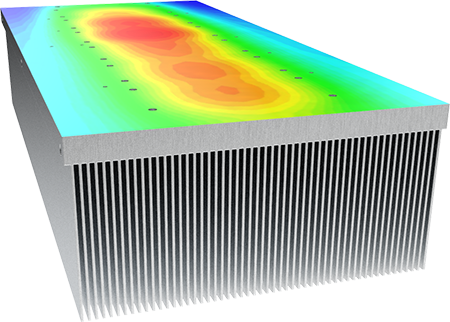

The growth of cloud computing and big data has driven demand for effective thermal management solutions in data centers. Servers and data storage systems generate vast amounts of heat, and failure to manage this heat can result in downtime or data loss. Custom heat sinks for data centers must be capable of dissipating heat efficiently in a highly compact and densely packed environment.

Custom heatsink manufacturers for data centers focus on developing heat sinks that provide maximum cooling efficiency while occupying minimal space. Advanced designs, including heat sinks with optimized fin profiles and integrated liquid cooling, are often necessary to meet the demands of modern data centers. Manufacturers must also ensure that the heat sinks are easy to install and maintain to minimize disruption during servicing.

Choosing the right custom heatsink manufacturer depends on the specific requirements of your industry and application. Whether you need a heat sink that can withstand the rugged conditions of the automotive sector or a lightweight, efficient solution for consumer electronics, the ability to customize the design, materials, and manufacturing process is crucial for optimal performance. Comparing custom heat sink solutions across industries reveals the importance of precision engineering, advanced materials, and reliable performance in achieving effective thermal management tailored to your application.