Production Engineering: The Life Enhancing concept of Interchangeability

Hi, dear Steemians! I hope you' re doing great

It's nice writing again and I must say, I've missed you all. Thanks for the continuous support and love shown so far.

Lately, I've been writing on Technology related articles and Mathematics a couple of time.It's not that I forgot my root as a Mechanical Engineer but, I just had to pause on it a lil bit so as to share those fabulous articles and I'm sure you learned a few things yourself.

My last post on the Reality Technologies (VR, AR, and MR) and the golden mathematics of the Fibonacci Sequence received lots of comments and reaction which made me happy and motivated.

Today, I'll be revisiting my lane (Mechanical Engineering) and take you along on the journey - I hope you enjoy it as usual!

Yesterday I was with my uncle's wife. I and my cousins had to help her assemble some parts of the industrial sewing machines she bought recently. I was at the forefront trying to proof Superman being a recent mechanical engineering graduate (food for me, right?)

You might think I want to tell you about how I dazzled or more pitiably, how I sucked as some people might think. Well, today isn't for that, maybe later though.

We took the machines out of the store and separated the parts according to their models and types, we began to put the parts together and then as we worked on them, my cousin alerted us about a missing part for one of the machine stands. I went to his side and checked around in case it was lying somewhere unknown to us.

But the search was to no avail and this left my Uncle's wife panicking already as she had received the order for those particular type of machine.

I entered the store again and was lucky to find a stand detached from the other part - it was from the previously stocked machines. I removed the screw and nuts took the part we needed for the other machine and tried it.

Lo and Behold, it fitted in perfectly albeit the rough looks though (a little rust and fading of the paint from abandonment I guess). She was happy seeing it saying "I forgot we had something like it from the last stock I made". We coupled the parts and moved the machine to her shop for inspection and sale to the buyer.

Thinking what is mechanical about that, right? I would ask that too if I was not conversant with the term "Interchangeability!".

As we may have noted from the scenario narrated, it was only because the parts are interchangeable that we were able to take a part from one machine to another without any major modification or process.

The Concept of "Interchangeability" is core to the operation of Production Engineers and is vital for any production system.

Today, I'll be talking about types of Production, Standardization, and importance of Interchangeability in a Production system. Stay with me!

Wikimedia Creative Commons : Yarn Production line.

To start with, I'll like to first familiarize u with the term Production and Production system which forms the basis of today's topic of discussion.

Production in the simplest term involves the transformation of input raw materials into processed outputs which could be a product or service. The concept of Production involves three stages as below:

Wikimedia Creative Commons : Production process

I hope that gives us the picture of what production entails.

In the industrial world, each of these stages embodies numerous systems of operation before production materializes into a product. Thus, we can again say that production is a step-to-step transformation of a form of material to another through a mechanical, chemical or biological process thus enhancing the utility of the product to the user. It is a value-adding process made up of many sub-processes.

Each manufacturing industry, however, has its own production system that determines the level of production, the types of process, machines and thus the product outputted.

A Production system is the organization's style of production that dictate how the resources flow within the organizational setup to generate the product. The production system determines how large the machines needed would be, it takes care of the number of output and the interval of production. This leads us to the types of production as classified by the type of production system.

The major types of production existing in industries are the Job Production, Batch Production, and Mass Production. I would highlight in few paragraphs what these types of production entail so that we can get an insight into them.

As the name implies, Job production system is dictated by the job received. Its production is in accordance with the order received from customers. Production is usually done intermittently as orders are being received. This is done with the aid of general process machines suited to the particular product ordered.

The products from a Job production are usually special, peculiar, and non-standardized because they are produced in varying sizes and nature.Job Shop production is hence characterized by low volume varying goods and requires a skilled operator in carrying out the production as the product dictates. Book printing and bridge building is a perfect example of a Job Shop production system.

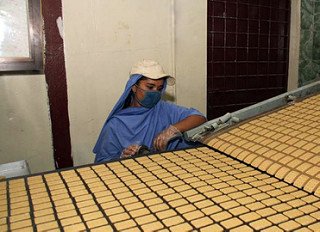

The Batch Production system is a repetitive production system where an increased number of a quantity of a particular ordered product is produced in batches. The quantity is usually known in advance and is made according to the demand of the customer.

It is similar to Job production just that more quantity of a specified product is produced at once. Instead of making a single product as in the Job Production, a batch of the product is produced at once.However, it should be noted that one batch of the product may not exactly resemble the next batch.

Batch production is pronounced in the production of products like biscuits, confectioneries, medicines, canned food and so on, that are produced in batches according to demand or the market. Small or large batches (or lots) of this product are produced in a specified quantity at intervals.

The Mass production, the most widely adopted form of production, as its name implies involves the production of products in a large volume through a continuous process. Standardization is the basis for Mass Production and thus, standardized products are produced using standard process and standard machines in a continuous manner.

The flow of production is set up such that each machine involved in the production is lined up in a sequence that ensures that as one operation finishes, the product is passed to the next in a continuous form.

In a Mass Production system, a large quantity of identical product is generated and thus, this tells us that the nature and sizes of the products depend on the specification and standards. This leads us to the importance of the concept of Standardization.

Standardization is the process of defining some set of rules and technical guidelines that everyone can adhere to. Standards are established through consensus of different bodies and is laid down as the benchmark to be followed and with which quality of a product is measured.

Standardization in production covers all properties of the product, the physical, geometric or chemical properties. For an engineering product or process, for instance, standardization cover the dimensions, allowances and tolerances, materials specification and properties, machines and tools to be used, methods of installations and even the process of inspection must be done in a specified and established standard.

The main aim of standardization is thus to ensure interchangeability, quality enhancement, cost reduction, protecting the Health and safety of consumers, variety reduction, transfer of technology and improved efficiency.We can then say standardization ensures products are produced according to a standard and by so doing, interchangeable parts are achieved. This leads us to the concept of interchangeability and I'll explain it in few paragraphs below.

Don't read the line above if you're following - it is evil!

Interchangeability is a system that allows for any component to be assembled correctly with any mating part chosen randomly from a pool of similar parts. This allows for quick repair and forms the basis for mass production of identical products in large volumes.Before the 18th century, devices were usually made by goldsmiths in a unique manner and functionality. Once there's a damage to a part, the device is either discarded or sent back to the goldsmith for custom repair. In the early 19th century, the need for a system of interchangeability then became continuously wanting and led to efforts that yielded the now enjoyable concept of interchangeability notably referred to one of the greatest achievement of the 20th Century.

Interchangeability makes it possible to save cost as some parts of a product may have a short lifespan and may become faulty while the product is still considerably new.

Imagine what it would be like if there wasn't anything like interchangeability and just the bearing of a car spoils and you have to buy a new car?

Imagine losing your computer just because you mistakenly break the screen or phone just because some key isn't pressing?

How would it feel? The cost? The files? Mehn, I can't think it!

We must, however, note that interchangeability doesn't mean a "perfect replacement" or like my lecturer will say, it isn't a "copy and paste" affair but rather, it involves producing parts that are within some allowed limits or tolerances which could still fit in at least 99% if not 100%. This concept explains why an interchangeable system is sometimes referred to as a Limit System.

The Limit system caters for the inevitable inaccuracy of manufacturing methods and the imperfections of the operators and by such allows production to be done within two extreme ends known as the upper limit and the lower limit.

In explaining a limit system, the followinbgng terms are used and tells us the different variatons allowed for interchangeable parts.

- Nominal size

It is the size of a part specified in the drawing for its general identifical. The sizes we see for a particlar machine meber is its nominal size

- Basic size

This is known as the theorectical size of a part where all limits of variation (upper and lower) are applied to arrive at final dimensioning. The basic size i oftensame with the nominal size.

- Actual size

This is also known as the design size and it is the actual measured dimension of the part after consideration of all variations. It is equivalent to the Maximum Material Condition of a part. The difference between the design size and the basic size must stay within the allowed limits so as to make it intercdhangeable.

- Tolerance

Tolerance is known as themaximum allowable variation in the dimension of a part. It is the difference between the

specified upper and lower limit.

It can either be unilateral or bilateral. When all the tolerance are one-sided, it is unilateral system but if splitted equally on both sides of the nominal size, it is said to be bilateral.

- Allowance

In case of mating parts, allowance is the intended difference between the parts. It may be positive or negative. Say a shaft to be fitted in a hole, the allowance is positive if the shaft is smaller than the hole and negative if vice versa

The interchangeable parts are produced within this specified allowance and it ensures that even when there are variations, the set limits makes it possible for the parts to be able to properly replace one another when picked randomly.

The Significance of the concept of Interchangeability in Production hence becomes numerous and vital.

As said earlier, Mass production is achievable because of the concept of interchangeability facilitated through standardisation. Without it, identical parts would need to be manufactured singly and would not correctly replace each other in an area of application and hence slows down production and reduce yield.

Interchangeability saves us a lot of money! If there was nothing like interchangeability, parts that are expensive and delicate becomes a burden when they spoil and would incur a lot of cost to produce another similar one that replaces it completely. But with interchangeability, numerous copies of it is made together and would be easier to replace it when the need arises

More than cost and quantity, interchangeability saves us resources and still enhance quality product realization. Instead of pulling materials to make a single part all over each time it spoils, the materials can be put together to produce numerous parts that are interchangeable.

Interchangeability relief us of stress and make productivity increased significantly

I wondered, what if we hadn't seen a fitting part while trying to assemble the sewing machine parts? The money we would have lost? The reputation and disappointment?

It is by far one of the greatest accomplishment of scientists and is a great relief to man.

Thanks for reading

REFERENCES

- Ismaila S. O., 2001. "Production Engineering II". Department of Mechanical Engineering, Federal University of Agriculture Abeokuta.

- Mahmoud A. M., 2015. "Classification of Production Systems". Industrial Engineering Branch, Department of Production Engineering and Metallurgy, University of Technology, Baghdad - Iraq.

- Knyazyev M. K., Dyadin V. O., Bilokun B. S., and Kurin M. O., 2012. "Basics of Interchangeability". Ukraine

- Mechanical Engineering | Interchangeability

- YourArticleLibrary | Types of Production: with it’s Characteristics and Limitations

- Fundamental Concepts | Interchangeability

- Wikipedia |

Interchangeable parts

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

@mrbreeziewrites ,you just breezes cool air into my system. I got nocked off from my confusion of all the Engineering terms when i got to this point;

Imagine what it would be like if there wasn't anything like interchangeability and just the bearing of a car spoils and you have to buy a new car?

At that point I came alive.So interchangeability is like when you steal chicken in your mama pot and replace it with beef.....Did I just typed that ?.....Well, nevermind.

I enjoyed reading this post. I learnt alot even including types of production systems.

Lol...I warned not to read those tiny lines...

Glad you enjoyed it..Thanks for stopping by fam!

We stay together . I have an eagle eyes, so that's why 😁

This is an amazing post mate, congratulations!

Without interchangeability our wealth in general will surely be lower, because productions costs will be higher and the purchasing power of the people will therefore be lower as a result.

As always, the more efficient our technology and techniques, the better the results we will get and the more enjoyable the life for every consumer.

Cheers bud!

Thanks for this insightful comment. I appreciate your input to the topic of discuss.

This is a very solid point. Interchangeability will greatly affect purchasing power and our wealth may not suffice.

Thanks for stopping by!

Interchangeability is the term that saves us all and without it the production process would be a different playground as it would be difficult to produce one part just for one machine.

Also saves cost of production this is why production engineers welcome the use of tolerance and clearance in making machine parts.

I hope you proved them wrong. Well done mr breezie!

Entirely new playground, a survival of the fittest and we would have a lot of poor people because of it as even the richest will struggle to purchase things because interchangeability is nil.

Thanks for stopping by. Your input is much appreciated.

You are right.. and you are very much welcome.

Keep educating us.

It's a pleasure 💪

Interchangeability has afforded us many advantages. Like you noted:

This is really a solid point.

I remember during my industrial training, we replaced series of car components daily and the customers go back home with smiles on their face. Thanks to interchangeability.

Well done.

More advantages than we could imagined.

Imagine it doesn't exist, you guys wouldn't even have a "workplace" as there'd be nothing to replace.

Thanks for stopping by... I appreciate.

Engineering does make life easier for everyone.

I can't even imagine how life would be due to high cost of stuffs if there wasn't interchangeability in production processes.

Just don't let us imagine it! Cos it'd be unthinkable!

Thanks for dropping by!

Great in-depth post. In telecommunications standardization is crucial to ensure solutions working end to end with different vendors. Thanks.

Thanks for the comments.

Standardization makes the world what it is.

I appreciate

Bravo. This is nice writing. I haven't for once considered interchangeability as an engineering terms. I had always thoughg it was a norm.

We live in a world where the simple things around us are wired in engineering.

Thank you man for this.

Exactly, thanks for acknowledging the fact. I am glad I'm able to introduce you to it.

Thanks for stopping by.

Prof. Ismaila would be proud of you! I wish i read this post before my exams, maybe i would have had a higher grade but you probably haven't joined steemit by then.

Interchangability gives us the ability to get things fixed without worrying about the "original". Great post sir.

Lol. Even I didn't understand it this much then.

Yeah, we wouldn't be too careful protecting just the original.

Thanks for stopping by.

This is something very important, I love this. There are certain trends in the type of production depending on the type of industry as well. Great Post!

Yes! Well said...Thanks for stopping by