Electric cars, talk dirty to me

Electric cars might be one of the hottest topic of the moment, they are letting very few people indifferent. Lately, there has been a lot of friction between the ones who loves them and those who hate them. Being in the mobility industry for 4 years, I’ve been amazed to see how divided the opinions are on the subject. After deep analysis, I think it all comes down to a lack of precise data combined with misinformation. The main divergence point is around their core structure: Electric cars are not any better when it comes to pollution. They are actually few key points that leave people confused; and for good reasons, details matter and are hard to grasp. The first is that manufacturing electric vehicles has a larger carbon footprint than their gasoline counterparts due to the additional assembly lines for batteries. Speaking of batteries, many people are concerned about the way the materials composing them are harvested and processed, notably around all the chemical processes surrounding their extraction and transformation. Some also believe that driving old used cars could be better for the environment because it would be saving on the environmental impact of manufacturing a new vehicle (since the car already exists the environmental price has already been paid). To be clear, the argument is that electric cars are not as healthy for our planet as one might think and potentially harmful. A wide variety of opinions have been expressed on the subject but very few backed by actual data and science. Therefore, the question still lies: what is the real environmental impact of electric cars?

One of the first things to consider when talking about environmental impact of an object is the carbon footprint through its entire life. What that means is how much greenhouse gases will be released when manufacturing the object but also throughout all of its utilization until it can’t be used anymore. What is interesting to look into is how the different type of vehicles compare and how they differentiate themselves.

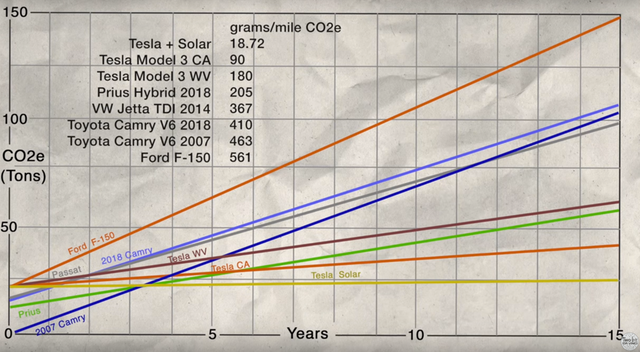

Looking at the US, the adult population is around 250 million people, and believe it or not, an astonishing 275 million vehicles are currently registered. Around 17 million new vehicles per year enter the market. Because not everyone drives, we could technically stop producing car en masse and only renew dead vehicles. Even assuming their manufacturing footprint is zero because the environmental cost has already been paid years ago, how do they compare to the new ones that are built? The average vehicle age is about eleven years, and the most sold vehicle over the decade is the Toyota Camry; it makes sense to use a 2007 Toyota Camry as the old vehicle reference. It can be compared to a brand-new Toyota Camry (2018), a hybrid Toyota Prius (2018), a diesel-powered Volkswagen Jetta (2014) and the number one vehicle of 2018 in sales numbers: The Ford F150. For electric car, the reference will be the best-selling electric car on the market Tesla Model 3 long range rear wheel drive (2017).

The main points to take in consideration to evaluate the complete carbon footprint of building a new car are: the total amount of greenhouse gases produced to power the factories, to build the vehicles, to directly and indirectly to transfer components, as well as the cascading emissions of each suppliers. That is where all the troubles start. Automotive manufacturers are not making the data about their supply chain public which makes it harder to exactly track down all emissions. That said, it’s important to note that the manufacturing carbon footprint of similar vehicles (same model, same year) produced in two different factories can vary a lot depending on how the different parts are manufactured, transported, how energy efficient the factories are and how far apart all the suppliers are from the final manufacturing assembly. Taking into account all these factors would be required to find the exact metrics, that said an estimation that not too far off from reality can be determined by doing an assessment using vehicle weight, material, and overall factory location. It is not so surprising that these criteria propel the Tesla Model 3 as the top polluter.

Next step is to look into vehicle consumption while driving over a lifetime of 15 years, this can be easily found using the mile per gallon and mile per gallon equivalent available on the Environmental Protection Agency (EPA) website for each car. However, for the environmental impact of electric vehicles to be accurate it needs to be derived from how the grid electricity is produced. There are 3 different interesting situations to look into: one powered mostly by home solar, another one being in a state like California (50% natural gas, 40% renewable, 10% nuclear) and the last one being in West Virginia (90% coal).

Combining the manufacturing footprint and the efficiency over the life time of the car finally (using an average of 12,000 miles per year) will give the full environmental impact of every vehicle.

Within 4 years the Tesla powered by solar would have the lowest environmental footprint. It would take 6 years for the Tesla in California to be cleaner than a gas-powered vehicle and 16 years for the one in West Virginia.

The second thing to evaluate is the environmental cost of mining and extracting all the different elements that make the vehicle’s battery. That may sound surprising but creating a lithium-ion battery is not simply a matter of digging materials from the ground and directly shoving it into a pack. There are a lot of components parts that constitute a lithium-ion battery and there’s tens of different types of chemistry in so called lithium-ion batteries. To simplify, the overall structure of a battery is made of two electrodes (cathode and anode) and an electrolyte solution (lithium hydroxide) through which the electric charge flows. In order to move, electric cars need to deliver current to the motors, this is achieved by closing the electric circuit which lets lithium ions in the electrolyte solution move from the cathode to the anode thus generating electric current. During charging the flow is reversed, the current put into the circuit forces the ions to move back from the anode to the cathode. This is where the name “lithium-ion” comes from but that’s not all. The beauty of it is that because different molecules have different physical properties by tweaking the components in the battery you can achieve faster charge time, better capacity, lighter mass, longer lifespan, etc. To make a long story short, depending on the desired properties of the battery the chemistry of the cathode and the anode may actually differ a lot, so much so that all lithium-ion battery cannot be considered equal.

Just focusing on the electric vehicle market, from one brand to another, the battery chemistry can be so different that a deep analysis would be required to properly assess the vehicle environment impact. In this case and for brevity the focus will be exclusively on the most efficient battery on the market (which also happen to be using a more environmental friendly chemistry but more on that later): The Tesla 2170 cells used in the Model 3. The cathode has a nickel-cobalt-aluminum oxide chemistry with a ratio of 8:1:1 (80% nickel, 10% cobalt, 10% aluminum), the anode is a mix of graphite for the most part with silicon. To really understand the environmental impact of a model 3 battery we need to look into what are lithium, nickel, cobalt, graphite, aluminum, silicon, how they are being extracted, and transformed into their final form.

Lithium is the lightest metal, it is pretty common (25th most abundant element on earth) and can be found in sea water. The current major producers are Australia, Chile, Argentina and China, with Australia and Chile accounting for about 75% of the total production. In 2015, subsurface brines, a naturally occurring concentrated solution of lithium mixed with other salts yielded the majority of the world’s lithium production. These brines are extremely concentrated in lithium and may contain more than four orders of magnitude than sea water. The extraction process is pretty simple: the solution is pumped out of the ground and put in large ponds for many months. Over time, the excess water evaporates and lithium can be separated from the other salts. The remaining lithium compound is then purified and processed. The main environmental concern, especially in Chile, is that the extraction can impact water supply in desert areas.

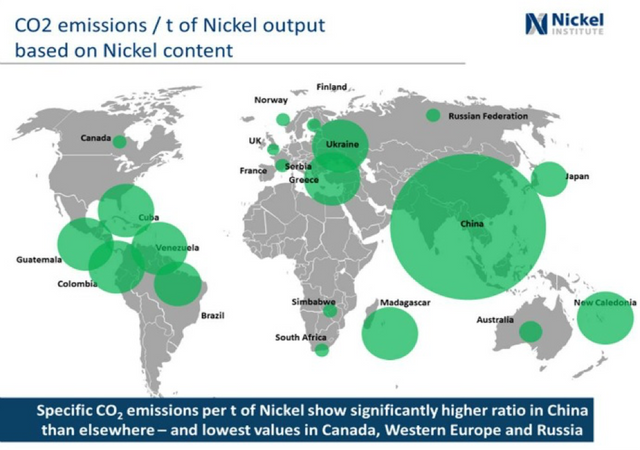

Nickel is the 5th most abundant element on earth and can be mostly found in 2 forms of ores: sulfide or laterite. Laterite is the most opulent form on the planet (70%) but the most common way to extract nickel is the use the sulfide ores. They are crushed and ground in order to liberate it minerals from the waste materials by selective flotation (a process to selectively separate different materials). After that, the Nickel ore is sent to the nickel refinery, where a complex set of reactions is carried out. These include leaching in autoclaves using ammonia and heated processes at high temperatures and elevated pressures to finally produce a 99.9% pure nickel with a solution that can be recycled. Operating the refinery could have a huge environment impact but it can also be addressed drastically, for example in 2016 Norilsk Nickel has reduced its use of coal-fired energy by 49%. The mining of nickel-rich ores themselves, combined with their crushing and transportation by conveyor belt, truck or train, can generate high quantities of dust in the air which contains high concentrations of potentially toxic metals, including nickel itself, copper, cobalt and chromium. Once again it all depends on the ethics of mining companies.

Like nickel, cobalt is found in the Earth’s crust only in chemically combined, it is the 32th most abundant element on earth. As discussed previously, it can be found and extracted from nickel ores, however most of the cobalt currently extracted today comes from copper-cobalt ores from Congo (65%). The ore is first roasted to remove sulfides, followed by a sulfuric acid atmospheric leach to split the different materials, and finally harvested using flotation. The environment impact is not too important however Congo mining conditions are one of the worst working condition in the world, and they include dangerous low paid job and child labor…

Graphite is also pretty common it is present in metamorphic rocks as a result of the reduction of sedimentary carbon compounds. The largest producers of graphite are China and India. It is obtained by breaking the rocks either by drilling or in some cases by using explosives, compressed air, or high-pressured water to cut open the rocks, which can lead to the release of hazardous fine particles in the air, exposure of workers and soil contamination from powder spillages (leading to heavy metal contamination of soil).

Aluminum is the most abundant metal in the earth’s crust, however it is expensive, largely because of the amount of electricity used in the extraction process. This is a two-step process that requires very high pressure and that produces “Red mud” a highly alkaline waste product composed mainly of iron oxide.

Silicon is the second most abundant element in the Earth’s crust, it is never found in its natural state, but rather in combination with oxygen. High temperatures are required to produce a reaction where the oxygen is removed, leaving behind silicon.

The common factors between all the different materials is that not only they can be found abundantly in nature but there are processes and places where they can be extracted and transformed with a minimal environmental and human impact. This is only the situation as it is today. Cleaner and more efficient mining processes are in constant development. Lithium Brines could be made more efficient by using heat (possibly from concentrated solar energy) so the pond could evaporate more quickly, the size of the pond can be expanded artificially. Waste management solutions are being conducted for example to develop uses of Red Mud applications such as production of low cost concrete, amelioration of soil acidity, carbon sequestration, etc. Recycling solutions are also being put in place: French carmaker Renault, producer of the Zoe (Europe’s best-selling electric vehicle in 2016) said that it recycles almost 70% of the battery weight and Tesla claims that the nickel in its vehicles is 100% reusable at the end of life.

The truth is that if electric vehicles can be a lot cleaner that gasoline cars they could also be more harmful for the planet. They can be extremely hazardous by using non-environment friendly chemical compounds in their battery packs, neglecting supply chain, or even the mining process. Today, Tesla has a clear lead in the space and not only because of their superior technology. It is true that their batteries use premium components but they are also committed to sourcing only responsibly-produced materials, forcing suppliers to provide certification of origin, performing on-site visits, etc. In addition, they are building vertically integrated factories, with solar panels, where raw materials come in one place and complete vehicles escape at the end, limiting the carbon footprint lost in logistic and during manufacturing. They are showing the example and hopefully others will follow. What really matters is the true intention of automakers. Will they continue to hide being their supply chain and work with unethical mining companies to boost their margins or are they willing to do everything they can to make electric cars cleaner and cleaner. Are they willing to evolve the chemistry in their batteries to build a potentially less compelling product but a more eco-friendly one? And that my friends that will be dictated by the consumer market. You and I, have the power to dictate what the race for electric vehicle should be about.

Hello @foreseetomorrow! This is a friendly reminder that you have 3000 Partiko Points unclaimed in your Partiko account!

Partiko is a fast and beautiful mobile app for Steem, and it’s the most popular Steem mobile app out there! Download Partiko using the link below and login using SteemConnect to claim your 3000 Partiko points! You can easily convert them into Steem token!

https://partiko.app/referral/partiko

Congratulations @foreseetomorrow! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!