FashionTalks:Topic2#Fabric

Hey everyone,

This post is related to fabric.

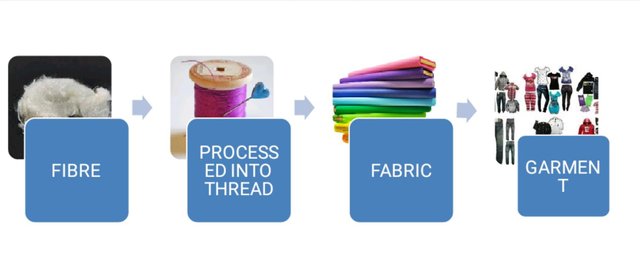

First let's talk about the process flow of garment you wear comes from. Last post was about threads and this post will majorly cover detailed information about fabric.

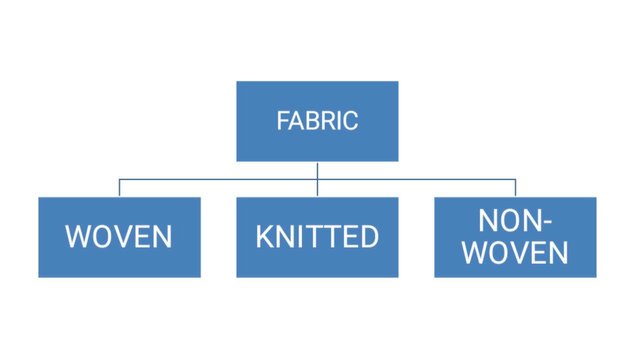

Fabric Classification

Woven Structure

Simple :Plain & its derivatives(warp rib, weft rib ,matt) Twill (warp face weft face & balance twill ) & its derivatives(Steep, Flat, Pointed, Diamond Herring bone, curve, figure, Diaper combination of Twill, Satin (regular irregular & its derivatives (crepe) Honey comb, huckaback, Mockleno etc

Complex : Extra warp, Extra weft, Double cloth treble cloth or multilayer fabric, Pique patent satin weft backed cloth Terry towel, etc.

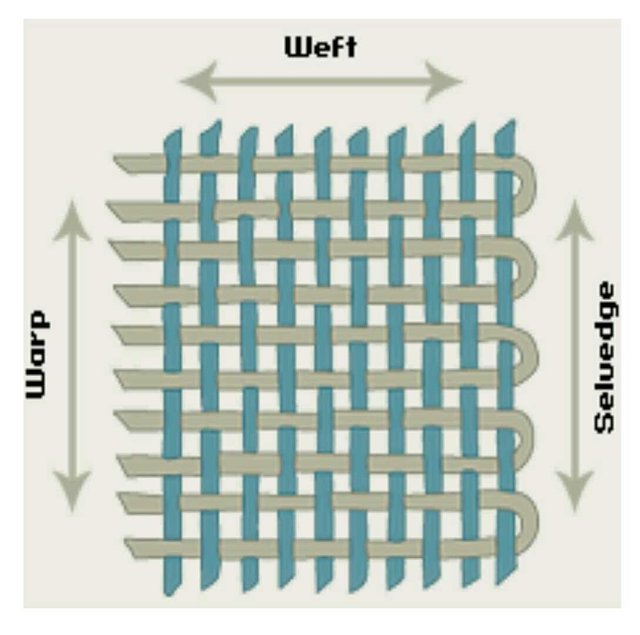

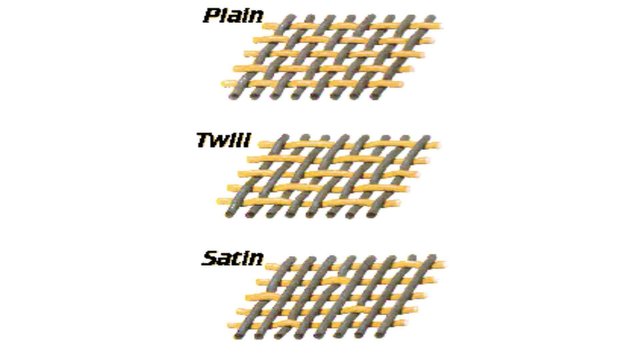

Fabric structure

The form of interlacing of warp and weft yarns can be divided basically into three categories- plain, twill and satin/sateen weave. These three kinds of forms are called basic weaves.

1.Plain Weave

The simplest of all weaves is the plain weave. Each filling yarn passes alternately over and under one warp yarn. Each warp yarn passes alternately over and under each filling yarn.

2.Twill Weave

A weave that repeats on 3 or more ends and picks & produces diagonal lines on the face of the fabric. A twill weave is characterized by diagonal rib (twill lines) on the face of the fabric.

3.Satin/sateen Weave

The satin weave is characterized by floating yarns used to produce a high lustre on one side of a fabric. Warp yarns of low twist float or pass over four or more filling yarns. The low twist and the floating of the warp yarns, together with the fiber content, give a high degree of light reflection. Weights of satin fabrics range from chiffon satin to heavy duchesse satin. The sateen weave is similar to a satin construction except that in the sateen weave, the filling yarns float and are visible on the surface of fabric.

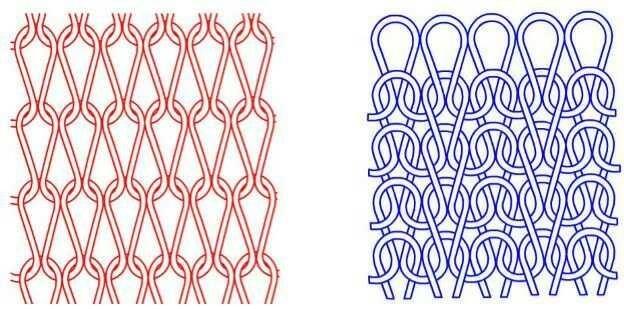

KNITTED STRUCTURE

It is a process of manufacturing a fabric by the intermeshing of loops of yarns.

Types Of Knitting

Weft Knitting is a method of forming a fabric by knitting means in which the loops are made in a horizontal way from a single yarn and intermeshing of loops takes place in a circular or flat form on a course-wise basis.

Warp Knitting is a method of forming a fabric by knitting means in which the loops are made in a vertical way along the length of the fabric from each warp yarn and intermeshing of loops takes place in a flat form on a length-wise basis.

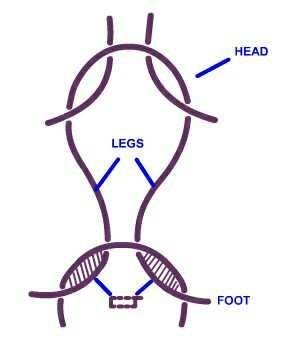

Basic Terminology Used For Knitting

image

KNITTED LOOP: The principal unit of a knitted fabric is known as the loop.

COURSE:Horizontal Row of loops in a fabric.

WALES: Vertical row of loops in a fabric.

NEEDLE LOOP: The top arc and two side of the loop.

SINKER LOOP: It is yarn that connects two adjacent needle loops

Basic weft knitted structures:

• Four primary structures

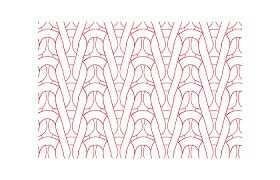

Plain (single-jersey)

V shaped loop appearance on technical face side& semicircular loops on technical back side and it is not reversible.

Rib (double jersey)

image

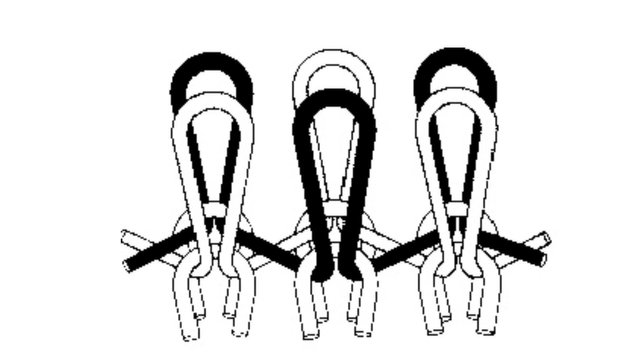

Purl

In these structures face and reverse loops are knitted in alternative courses. which can only be achieved with double-ended latch needles .

image

Interlock

By using a knitting machine equipped with two set of needles it is possible to make a fabric that resembles a jersey knit on both front and back. It is produced by alternating knit and purl stitches in both the wales and course direction.

NON WOVEN FABRICS

Nonwoven fabric is a fabric-like material made from staple fiber (short) and long fibers (continuous long), bonded together by chemical, mechanical, heat or solvent treatment.

image

Three Basic Stages For Making Non Woven Fabric

• Web Formation

• Web Bonding

• Finishing Treatments

- Methods for Web Formation

Drylaid

a. Carded

b. Airlaid

Spunmelt

c. Spunlaid (or spunbonded)

d. Meltblown

Wetlaid

Other technologies

e. Electrostatic spinning

f. Flash spun - TYPES OF BONDING

a. Mechanical

b. Chemical

c. Thermal

Application Of Non-Woven Fabric

• Personal care and hygiene as in baby diapers, feminine hygiene products, adult incontinence items, dry and wet pads, but also nursing pads or nasal strips.

• Healthcare, like operation drapes, gowns and packs, face masks, dressings and swabs, bag liners, etc.

• Clothing: interlinings, insulation and protection clothing, industrial workwear, chemical defence suits, shoe components, etc.

• Home: wipes and dusters, tea and coffee bags, food wraps, filters, bed and table linen, etc.

I hope this information will enlighten your knowledge of basics of fashion.

Please upvote and follow if you liked my post.

God bless all

Congratulations @fashion-talks! You received a personal award!

Click here to view your Board

Congratulations @fashion-talks! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!