Bridging A Gap In Agricultural Processing: "Design Of A Grinder For Processing Palm Oil"

Over the years there has been a gap in palm oil processing as regards grinding of the mesocarp of palm fruits, as early men used mortar and piston to pound their mesocarp. How would they produce palm oil in an economic quantity? This wasn't easy, and I can recall as a young man, I used to pound the mesocarp of palm fruit using mortar and piston for my parents. It was the most tedious labor I have ever engaged in.

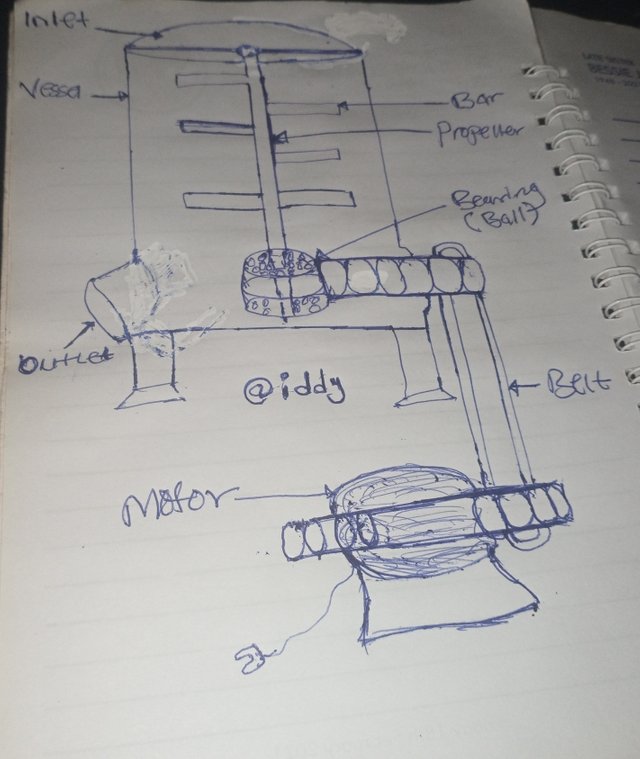

During my university days studying chemical engineering, I thought of how I could bridge this gap in palm oil processing, and the idea of designing and fabricating a grinder for this purpose came to my mind, and I succeeded. In this post, I will share sketchwork of the various components of the equipment (grinder for palm oil processing), its parameters, and the mechanism of the equipment.

THE COMPONENTS OF GRINDER FOR PALM OIL PROCESSING

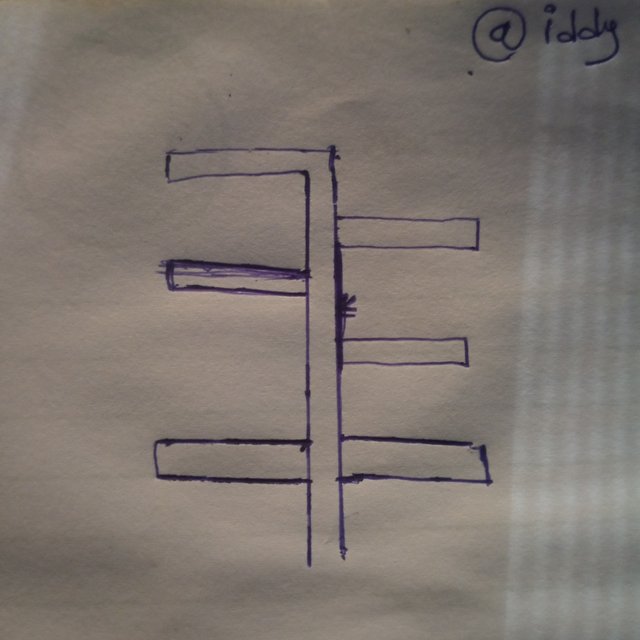

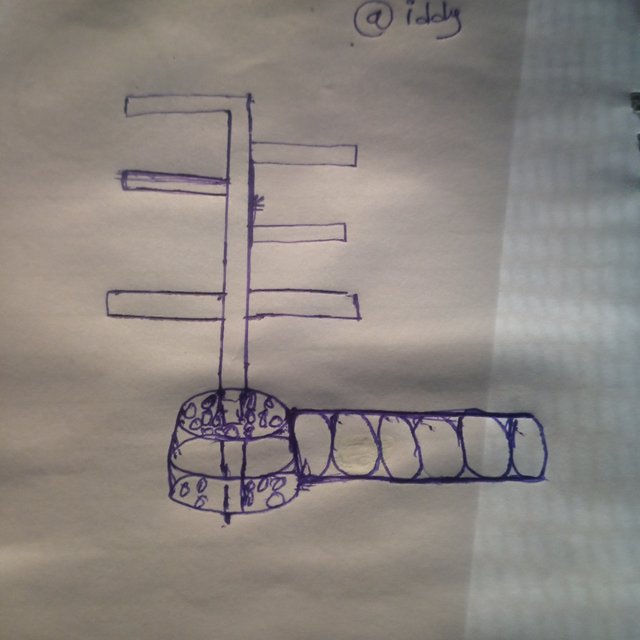

- Propeller and Bars: I needed something that would grind only the mesocarp of palm fruits and leave the kernel ungrounded. Crossbars would serve this purpose, but they can not grind the mesocarp if they don't apply force on it; the idea of a propeller came to my mind. The propeller would rotate the bars that are attached to it Have a look at the sketch work below;

- Ball Bearing: Something needs to cause the rotation of a propeller, and also reduce friction. To solve this, I fixed both ends of the propeller in ball bearings. Have a look at the sketchwork below;

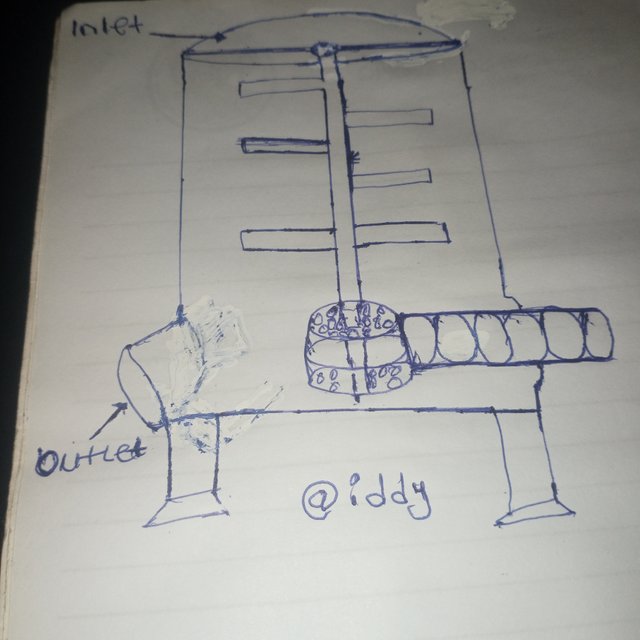

- The vessel: A vessel needs to enclose the propeller and bars. This vessel would serve as the container in which the raw material ( palm fruits) is fed. The vessel should have a kiln shape, the opening in which the raw material is fed(inlet), and the opening from which the ground mesocarp is received (outlet). Have a look at the sketchwork below;

- A Motor: This is the source of force. It is the force supplied by a motor that propels the propeller and, in effect, the bars.

Parameters Of The Components Of Grinder For Palm Oil Processing

This depends on the individual's preference. But in my design of a grinder for palm oil processing, the following are my parameters;

kiln drum or the vessel: I used 572mm as the diameter of my kiln and 851mm as the height of my kiln. The circumference of the kiln is 2πr = 2×3.14×286= 1796.08cm

propeller: I used 851mm as the height of my propeller for smooth running of the equipment.

Crossbars: My radius of the Crossbars in the grinder equals the diameter of the kiln divided by two( r=diameter/2), which is 286mm

Motor: I used the mechanical motor to avoid the stress of calculating the horsepower of the motor that can ruin the equipment perfectly, so I used a Lister engine( 8.0hp). I believe an electric motor of about the same horsepower(7.997hp) can run the equipment, too.

Mechanism Of Grinder For Palm Oil Processing

The motor sends 8.0 horsepower of force to the rotary belt, and the rotary belt receives the force and begins to rotate

As the belt rotates, it sends the same amount of force to the pulley of the Grinder (equipment) to which the propeller is attached.

The propeller to which crossbars are attached receives force, and it begins to rotate simultaneously with the crossbars

At this moment, the palm fruits are fed in the inlet of the equipment and the outlet is closed.

As the propeller and the crossbars are rotating, the cooked palm fruits are also rotating and colliding with the crossbars. As the palm fruits collide with the crossbars, that force of collision causes them to be grounded

When the palm fruits are fully grounded, open the outlet, the rotary force would naturally dispense the ground mesocarp from the outlet.

Grinder in physical

The equipment can be operated intermittently, and used in grinding as many mesocarps of palm fruit as possible, and it operates faster than using the manual grinding process ( mortar with piston). With this equipment, the economic quantity of palm oil can be processed in a day with ease. This design has bridged a gap in palm oil processing.

Thank you for reading. I welcome your contribution.

Best regards

@iddy

X-shared;

https://x.com/iddy_e_okon/status/1855718132226179182

Upvoted! Thank you for supporting witness @jswit.

@tipu curate

Upvoted 👌 (Mana: 1/7) Get profit votes with @tipU :)

Thank you very much, @muzack1, for the support.

Welcome to steem-agro!

MODs Comment/Recommendation:

Thank you so much dear for posting in our community.

Remember to always share your post on Twitter using these 3 main tags #steem #steemit $steem

Thank you for the verification.