Bismillahirrahmanirrahim. hello friend this

@mdyousufali. everybody will come to our online flat from

@steam.com. now I am discussing a process flow chart. Color fastness to fire respiration in text have industry. so this method is very helpful our test measurement or test performance interesting laboratory. so let's go now I am started our test method color fastness to participation. today I go to a performance in testing laboratory according to ISO 105 E04 2013.

# PRINCIPLES OF COLORFULNESS TO PARTICIPATION:

the specimen of the textile in contract with the adjacent fabric. Altrate in the two difference solution and containing the histodine. drain and place between two plates under the specimen pressure and the test device. the specimen and the adjunction fabric are dried separately. the change in the color and is specimen and straining of the adjacent fabric are assessed by the comparison with the gray scales or instrumental.

Apparatus and material.

Test device : Test device is containing of the form of stainless steel into which the weight pieces mass approximately 5 kg. the base of the 16 mm into 150 mm is closely fitted. so that the pressure 12.5 + - 0.9 kilo Pascal. can be raising plate and measuring X approximately 16 mm into 150 mm. into 1.5 mm. this test device shall be constructed so that if white pieces are removed during the taste and pressure remaining and change. if the dimension of the composite specimen differs from the size 40+ - 2 mm into 100 + - 2 mm.

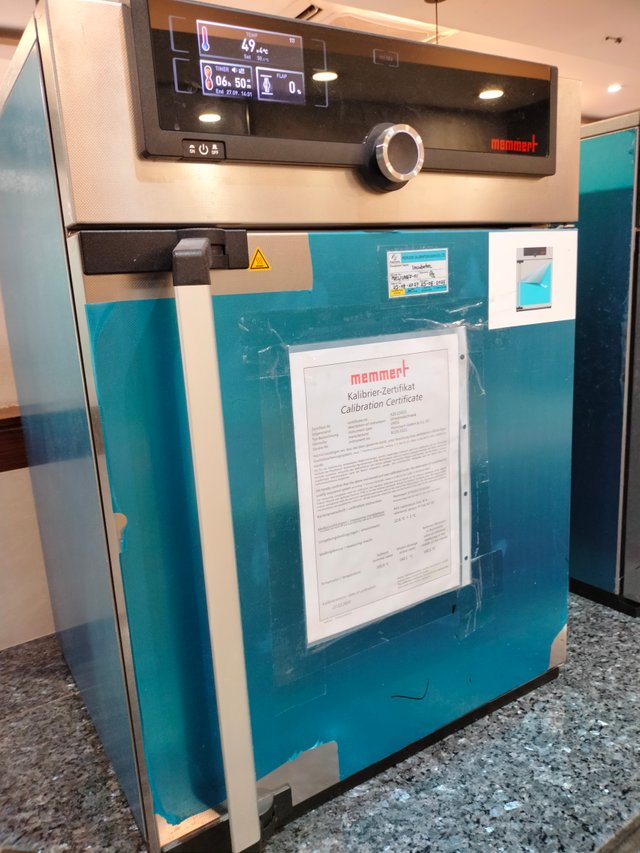

Oven:

maintained at 37 + - 2 degrees Celsius

Alkaline solution:

➡️0.5 gram per liter instead of mono hydrochloride monohydrate.

➡️5 gram per liter sodium chloride. 0.2 gram per liter sodium hydrate orthophosphate dihydrate. please should be 8 + - 2.

Acid solution:

the solution should be freshly prepared using battery water compelling with ISO 3696 containing per liter.

➡️0.5 G per liter in history in monohydrochloride monohydrate.

➡️ 5 gram palette sodium chloride.

➡️ 2.5 gram per liter Sodium hydrogen orthophosphate dihydrate. pear should be 5+ minus 2.

place to the device containing the composite specimen oven for the 4 hours. 37 + - 2 degrees Celsius. positioning so that the test specimen are either the horizontal position or vertical position depending on the type of device available. open out is composite specimen by breaking the stitching concept of the shortest side and dry by the hanking in the year temperature not existing 60 degree Celsius..

this is specimen test we are using the adjacent fabric. the adjacent fabric contain the seven types of the fiber are used to make the adjacent fabric this called the multiple. if the fast specimen is

, cotton, wool, viscose, poliomite polyester, acrylic.so it is called multifiber

Procedure: lay out the composite specimen smoothly in the flood bottom dish and cover the alkaline solution. choli weight composite specimen in this solution page 8 + - 2 approximately liquor 50:1. and allow into the remaining solution at bottom temperature for 30 minutes press and move to from time to time good uniform penetration of the liquor. pore of the solution and with the excess liquor of the specimen between two glass rods. Place the composite specimen between two glass or acrylic glass plates. under normal place to Bharat Desh Mein pass 12.5+-2 and place the test device. same procedure for alkaline and acid. specimen procedure weight composite specimen acid solution PS 5.5.

# test report.

the test report shall be including the following information. reference to the park ISO 105 is 04. all details necessary for the identifying for the sample test. the material gray skill and retaining for color change and color staining the specimen or e-solution. if the single fiber adjacent fiber where used the new medical gray scale rating for the is kind of the adjacent fabric used. if the multiplied adjacent fabric was used the numerical gray scale rating or instrumental assessment for the stunning or is type of the fiber or modified at the same fabric and the type of the multi adjusting fiber are used.