Improving Drilling Mud with Soda Ash (Sodium Carbonate, Na2CO3) and Barite (BaSO4) | An Original Research

On the 6th through the 9th of August 2019, I was opportune to attend the Nigerian Society of Engineers (NSE Uyo Branch) 2019 Tech-Innovation Engineering Conference and Exhibition. It is usually an impactful and interesting gathering of engineers all over the state.

So last year's edition of the conference had the theme to be “Local Content Innovation in Engineering for Sustainable Economic and Industrial Development of Akwa Ibom State and beyond.” Thus the entire focus of the meet up was being centered upon the need for local content sourcing and development in all respective engineering fields.

It is believed that the conference theme came up considering the fact that almost all, if not all of the equipment and materials being used for operations in Nigeria (especially in the Petroleum sector) are being imported whereas some of these materials are readily available in the nation and could be quite useful, if harnessed and developed upon appropriately.

This then gave the drive and motive to undertake this very research project on improving Nigeria local clays so as to serve as a substitute for the imported Bentonite in drilling fluid applications. For this reason, local clay was obtained fro Uyo and drilling fluid formulated using it as well. The density and pH value was measured and recorded accordingly. Also, barite and soda ash were added in various proportions to the formulated mud; their effects on the mud pH and density was also recorded.

The results of the research will be quite beneficial to petroleum engineering students, research institutes and indigenous oil and gas companies in Nigeria. In a case where the results of the research prove that the addition of these additives to the local clay will help improve it, indigenous companies will have the confidence to start utilizing and harnessing local contents.

From the foregoing, there is a great need to develop local contents for use in the oil and gas industries in Nigeria as it is necessary for the sustainability of the sector. One cannot afford to keep buying what he has as it is a total waste of resources.

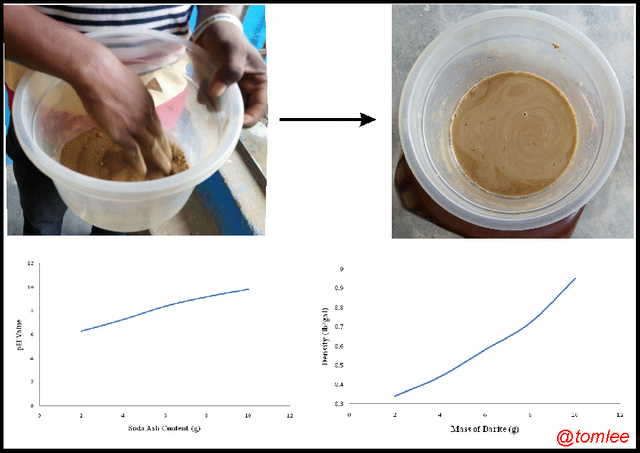

THE SODA ASH EFFECT ON LOCAL CLAY

Own Image

Own ImageDrilling fluid or drilling mud is simply the combination/ mixture of chemical, fluid (water or oil) and clay materials. Drilling fluid is however very vital and necessary for successful rotary drilling operations. Imagine someone trying to dig a hole down the earth; it will definitely be a tedious task if the person in question does not try to soften the ground first by applying some water on the ground.

The water will therefore help in making the ground soft for easier digging. In the same vein, that is the role of drilling fluid in drilling operations; it serves as a lubricating agent and thus enhances drilling. The Wyoming Bentonite has been mostly used for this purpose.

It is worthy of note that one of the main reasons Nigeria local clays are not being employed in the formulation of drilling mud is because of their high acidic content/ nature compared to how strongly alkaline bentonite is. This assertion is thus proven in the results gotten below:

Table 1: pH Values of Bentonite Versus Local Clay

| Property | Bentonite | Local Clay |

|---|---|---|

| pH Value | 10.60 | 5.12 |

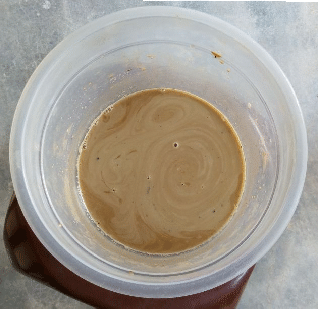

The results in Table 1 above show that the local clay is highly acidic (5.12) while the standard bentonite is strongly alkaline (10.6) in nature. The result further shows that there is a low concentration of sodium cations in the local clay which explains its low pH value. From Chemistry, pH scale helps in measuring the acidity and alkalinity of a solution or substance. Basic or alkaline water-based solutions tend have a high pH while acidic solutions have lower pHref..

Image Source - Wikimedia: Acidic (Red Region; Alkaline (Blue Region)

It is the alkalinity of bentonite that makes it the most preferred in drilling fluid applications as it poses no threat to equipment. On the other hand, employing the use of this local clay as it is (acidic) for drilling operations will end up corroding the drill rig components such as drill strings, drill pipes, casings, drill bits etc resulting in an unproductive operation. This then explains the avoidance of local contenting by companies in this area.

However, Soda Ash (Sodium Carbonate, Na2CO3) comes into play here. Soda ash is an inorganic compound that gives moderately alkaline solutions when mixed with water. It is a very useful additive whenever the pH of a mud is to be improved upon. Thus, it is quite useful for mud engineers. When added to the mud, it aids in reducing the acidity of the mud rendering it suitable for use.

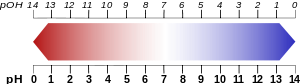

In view of the above, soda ash was being added in different concentrations (proportions) to the formulated drilling fluids using the local clay. The drilling mud was formulated using 25 grams of local clay against 350 milli litres of water, following the American Petroleum Institute (API) specification. Summary of its effect on the pH of the local clay is shown in the results presented below:

Table 2: Effect of Soda Ash on Local Clay

| Local Clay | Sample A | Sample B | Sample C | Sample D | Sample E | Bentonite (Reference) |

|---|---|---|---|---|---|---|

| Soda Ash Content (g) | 2 | 4 | 6 | 8 | 10 | Nil |

| pH Value | 6.28 | 7.25 | 8.36 | 9.16 | 9.76 | 10.6 |

Research have shown and proven that the presence and absence of sodium cations (Na++) is a factor that affects the rate of ions exchange in clays. Thus from the results obtained, it is evident that there was a very low concentration of sodium cations in the local clay which resulted in their its low pH value (5.12) initially - Table 1.

But from Table 2 above, the addition of soda ash to the said local clay caused an increase in the pH value. Meaning that there was an increase in the concentration of sodium ions as a result of soda ash's addition. Also, its introduction drastically reduced the acidity of the clay. Therefore, as the soda ash content increased, the more alkaline the formulated drilling fluid becomes.

Still to note is that the mud pH increased from an initial value of 6.28 to 9.79 (about 56%) at a concentration of 10g of soda ash (Na2CO3) to 350mL of the local clay mud. The results further revealed that the yield point, plastic viscosity and apparent viscosity increased by about 169%, 43% and 70% respectively. The graph below depicts the effect of soda ash content on the pH value of the local clay mud.

The Soda Ash Effect

Thus, from the results obtained, the pH of the local clay mud improved drastically with increase in soda ash content.

THE BARITE EFFECT ON LOCAL CLAY

Barite (BaSO4) is a known additive whenever mud density is to be increased. Low mud density could cause a kick which could eventually lead to a blowout in the well. This is so because when the mud density is low, the hydrostatic pressure in the column of the well will be low and hence, would not counterbalance the formation pressure. When the formation pressure is therefore higher than the hydrostatic pressure in the column of the well, a kick (or blowout) is inevitable. No driller or oil company wants a blowout occur as it is highly destructive.

A kick is a forceful flow of fluid into the wellbore. A blowout on the other hand could be said to be an uncontrollable release of oil and/or gas from the formation or simply put an uncontrollable kick ref..

On the other hand, high mud density could lead to what is called 'Lost Circulation.' This is the loss of drilling mud to the formation. This happens when the hydrostatic pressure is greater than the formation pressure in the well and this is greatly attributed to the mud density. It is thus necessary to always keep the mud density in check.

The control of the formation pressure during drilling operation with drilling mud is a direct function of the density of the mud.

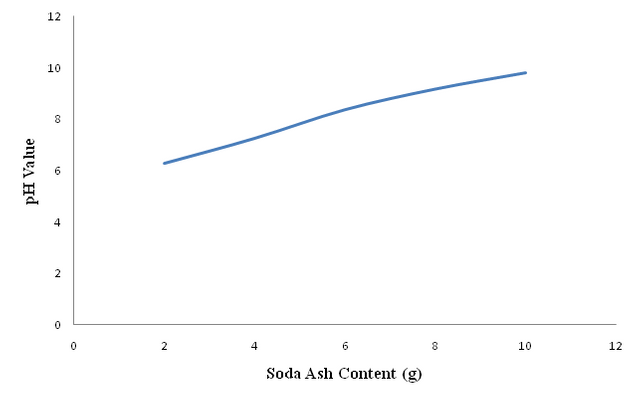

From the results of the experiment below, Nigeria local clays possess very low mud density and hence cannot be used for drilling fluid formulation as they could increase the chances of a blowout. The mud balance was used to measure the density of the local mud and that of bentonite. The result is given below:

Table 3: Mud Density of Bentonite and Local Clay

| Property, Unit | Standard Bentonite | Local Clay |

|---|---|---|

| Density, Ib/gal | 8.9 | 8.2 |

From the above results, the local clay has a low mud density when compared to bentonite. In order to increase or improve the mud density, barite was being added to the formulated drilling mud as a wighting agent. The effect of barite is thus seen in the results below:

Table 4: Effect of Barite on Local Clay

| Local Clay | Sample A | Sample B | Sample C | Sample D | Sample E | Bentonite (Reference) |

|---|---|---|---|---|---|---|

| Barite Content (g) | 2 | 4 | 6 | 8 | 10 | Nil |

| Density, Ib/gal | 8.34 | 8.44 | 8.58 | 8.72 | 8.95 | 8.9 |

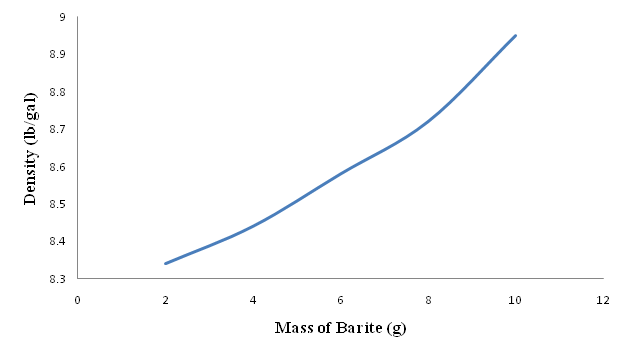

From the result in Table 4, it is evidenced that the density of the local clay mud improved significantly with increase in the barite content. The results obtained further show that the local clay density increased from an initial value of 8.20lb/gal to 8.95lb/gal (about 9%) at barite content of 10g to 350mL of the local clay mud. More so, the figure below depicts the effect of barite on the density of the local mud.

The Barite Effect

This development then implies that barite (BaSO4) can be used as weighting material in the formulation of drilling fluid using this local clay.

Conclusion

The local clay possessed low mud density and low pH (acidic) in its natural state which makes it unsuitable for use. However, at considerable concentrations of barite and soda ash, the local clay showed suitable mud density and pH when compared with those of bentonite. Thus, these additives enhance and improve the performance of the local clay thereby showing a possibility that drilling mud could be formulated using it.

(PS: This is an original research work conducted by the author @Tomlee. All experiments were carried out at the University of Uyo Petroleum Engineering Laboratory. Images are from the author except otherwise stated.)

References

https://en.wikipedia.org/wiki/Blowout_well_drilling

https://en.wikipedia.org/wiki/Sodium_carbonate

https://www.researchgate.net/publication/275334398_Selection_and_Application_of_Drilling_Fluids

http://jsaer.com/download/vol-5-iss-3-2018/JSAER2018-05-03-359-365.pdf

http://www.ijesmjournal.com/issues%20PDF%20file/Archive-2015/JUlY-SEPTEMBER-2015/3.pdf

http://futospace.futo.edu.ng/xmlui/bitstream/handle/123456789/1445/Igwe.pdf?sequence=1&isAllowed=y

http://jsaer.com/download/vol-5-iss-3-2018/JSAER2018-05-03-359-365.pdf

http://eprints.covenantuniversity.edu.ng/12564/1/1-s2.0-S0169131717301102-main.pdf

Interesting research friend @tomlee, I am passionate about reading your articles on drilling fluids, because sometimes I feel lonely when I publish this kind of topics, but since I discovered your articles I have already found a source to rely on.

I think it would have been good to compare the cost per bag of foreign bentonite, which is what you export, and compare it with the additives added to the local clay (sodium carbonate and barite). And in this way fully demonstrate the feasibility of the use in terms of cost optimization.

Regarding that the calcium carbonate decreases the acidity of the drilling mud and increases its PH, it is very favorable for the corrosion of the equipment, the other thing that can be studied and evaluated is also the impact that the ph and the acidity of the drilling mud have to run electrical records to evaluate the resistivity of the formation.

Referring to the density, I believe that the first thing that must be evaluated is what reservoir pressure is handled in the oil fields of greater pressures in nigeria, since if initially without barite the local clay handles 8.2 Lbs/gal of density, for example can be calculated the hydrostatic pressure that exerts that fluid for example to 5000 feet of depth with the following equation: Ph= 0.052 x 5000 feet x 8.2 lbs/gal, which implies that the hydrostatic pressure that fluid will exert with that density and at that depth is Ph= 2132 Lbs /square inch (PSI), then if for example if the reservoir pressure at that depth is 1600 psi, there would be no problem with a dummy and a possible blowout, Since there would even be approximately 500 psi of overbalance in favor of the hydrostatic pressure of the drilling fluid, of course this means that if we go deeper into the well we will find ourselves with increasing reservoir pressures, and if we need to increase the density at any necessary point there we need to add barite as a densifier.

Now for the other case you mentioned of fracturing the formation and that a loss of circulation can occur, this is really dangerous, because even this is another cause for which a blowout occurs, since the loss of drilling fluid, decreases the column of fluid and therefore decreases the hydrostatic pressure, and may be below the pressure of the reservoir. To control this it is necessary that the hydrostatic pressure never exceeds the formation's fracture pressure, this fracture pressure is just below the last casing shoe, this fracture pressure value must always be noted on the Company man's blackboard at the location where the well is being drilled.

As you can see friend @tomlee my comment is somewhat extensive, but it is that you inspire me to write since the topic that you mention excites me, since it touches my profession, greetings friend and I hope to be reading very soon with more of your articles related to investigations to improve the local clay drilling fluid of your country Nigeria, God bless you and have many successes.

This is awesome! Great insights and contributions. I really appreciate the detailed comment; I'm encouraged. Thank you

About the comparison between the cost of bentonite importation and that of the additives, I would research on that subsequently. But I am assuming that the importation aspect would be more costly considering that those bags of bentonite have to transported down to the country plus their purchase cost.

About the density, we know pressure increases with depth. Thus, it is incumbent on the mud engineer to always monitor the pressures both formation and hydrostatic to when we to introduce densifiers or dilute.

Normal pressures should be maintained at all times while drilling as either low or high could be detrimental to the whole operations. I look forward to having the practical experiences though in the near future.

This is another article in an article... Lol.. Wao

Exactly

Drilling is needed but fracking and other technology isn't very environmentally friendly.

Interesting ideas though. And way better to use a local clay than an expensive import.

Posted via neoxian.city | The City of Neoxian

Drilling is the best method of petroleum extraction for now and using local clay will help reduce operational cost.

Yep.

Posted via neoxian.city | The City of Neoxian

Esta publicación ha sido seleccionada para el reporte de Curación Diaria.

because you didn't use #steemstem :( it's an excellent publication

Thank you for the compliments.

But I posted directly in the community. Didn't occur to me that I still had to include the tag.

Edited though.

I think we still need to update our voting habits now the platforms have changed

Beautiful work. Please keep it up.

Thank you Sir

This post has been voted on by the SteemSTEM curation team and voting trail. It is elligible for support from @curie and @minnowbooster.

If you appreciate the work we are doing, then consider supporting our witness @stem.witness. Additional witness support to the curie witness would be appreciated as well.

For additional information please join us on the SteemSTEM discord and to get to know the rest of the community!

Please consider using the steemstem.io app and/or including @steemstem in the list of beneficiaries of this post. This could yield a stronger support from SteemSTEM.