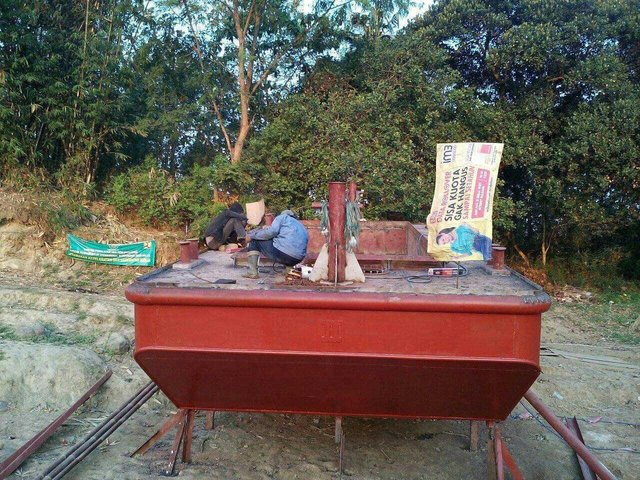

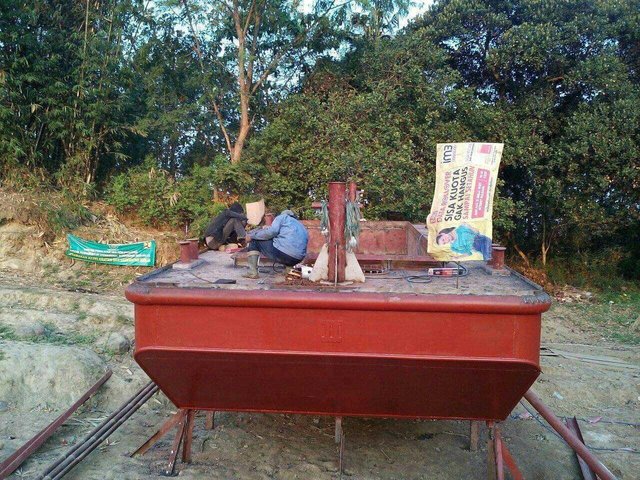

Construction of Shipbuilding Process Barge

Back again with me @vanirfan on the occasion last month I had time to post how to weld ace pipe, And on occasion This time I will post the process of making When is the barge Here are some ways of making it.

The type of construction used in Barge is the Longitudinal Construction system, but there is also a variation of longitudinal and transverse construction where the Cross Construction is used in After Peak / Forex area and Fore Peak / Ceruk Haluan only.

In order to more easily learn the construction of the ship, first must know the names of the parts of construction and its location, the material and how to make it.

Below you can see a cross-sectional image of a deck barge crane (Flat Top Barge) using Square Bilge or Chine as an example for studying construction.

Material, How to make it and Writing size in

Picture:

Side Shell Plate.

Material: Marine Plate - Mill Grade with Grade A. Grade can be increased to B or D depending on Scantling plate thickness value, required tensile strength and placement, for high tensile strength used Grade AH or DH.

How to make it: Sheet - by - sheet (sized) plate is connected to one another by means of an electric welder. Plate splicing refers to the Shell Expansion image.Writing Size: In the Shell Expansion image where there is an image of the Plate installed, the thickness of the Plat plate is inscribed on it by writing as an example eg the thickness of the Plat is 12mm then it is written; t = 12 mm or - See sample image below:

The Longitudinal Side

Material: Generally is Iron Elbow (Angle bar) or Plat Strip (Flat Bar) or Bulb Flat. Material equivalent to Grade A.

How to make it: After the Leather Plate is connected, the Elbow Iron is placed (welded) on it at a certain distance according to the Scantling calculation.

Writing Size: In the Construction Profile and Mid Ship Section image where there is a drawing of the Elbow Iron attached, the Flange size and Iron Elbow thickness are included beside it, for example suppose the size used is 100 x 100 x 10 Elbow Iron then written;Iron Round (Round Bar). In addition to the Round Bar can also be used Square Bar (Iron Box) or use Angle Bar (Iron Elbow) or Chine tampa wear without iron (without chine bar) but wear Doubler Plate. Material equivalent to Grade A.

How to make it: Round Bar (Upper & lower) is placed in position after Vertical Web Frame is connected with Leather Plate or can be after Vertical Web Frame, Chine Web Bracket and Wrang / Bottom Transverse are formed.

Writing Size: In the Construction Profile and Mid Ship Section images where there is a Round Bar image attached, the Round Bar Diameter size is included beside it, for example suppose the size used is Round Bar with diameter 2 "then written down.Marine Plate - Mill Grade with Grade A. Grade can be raised to B or D depending on Scantling plate thickness value, required tensile strength and placement, for high tensile strength used Grade AH or DH.

How to make it: Chine Plate is connected with Upper Round Bar and Lower Round Bar after Upper and Lower Round Bar are installed.

Writing Size: In Shell Expansion and Mid Ship Section images where there is a Plate attached, the thickness of the Plat is inscribed on top of it by writing as an example suppose that the thickness of the plate is 12mm then it is written; t = 12 mm (almost the same as the writing on Side Shell Plate).

Chine Longitudinal Stiffener.

Commonly is Iron Elbow (Angle bar) or Plat Strip (Flat Bar) or Bulb Flat. Material equivalent to Grade A.

How to make it: Stiffener is placed (welded) over Chine Plate after Chine Plate is installed on Upper & Lower Round Bar.

Writing Size: In the Construction Profile and Mid Ship Section image where there is a drawing of the Elbow Iron attached, the Flange size and Iron Elbow thickness are included beside it, for example suppose the size used is 100 x 100 x 10 Elbow Iron then writtenMarine Plate / Plat exclusively for vessels - Mill Steel with Grade A. Grade can be raised to B or D depending on Scantling plate thickness value, required tensile strength and placement, for

#How to make:

Stiffener is placed (welded) above Chine Plate after Chine Plate is installed on Upper & Lower Round Bar.

Writing Size: In the Construction Profile and Mid Ship Section image where there is a drawing of the Elbow Iron attached, the Flange size and Iron Elbow thickness are included beside it, for example suppose the size used is 100 x 100 x 10 Elbow Iron then written.

Once given a hole in such a way, then Vertical Web Frame placed on the Side Shell Plate and connected by welded.

Collar Plate

Marine Plate / Special plates for ships - Mill Steel with Grade A

How to make it: Collar Plate is made of plate with Rectangle shape (size adjusted to Scantling calculation) and placed on Chine Longitudinal Stiffener.For other parts of the barge the way of making is almost the same as described above as long as the material is the same.

Writing Size: In the Construction Profile and Mid Ship Section image where there is a Detailed image of the Collar Plate installed, for example the installed size is; length of plate 180 mm, plate width 90 mm, plate thickness 8 mm, then the writing is PL.180 x 90 x 8 mm.

#Note:

- All the connections in the construction using welding (welding).

- Before the material is used, the mill scale and rust should be removed first by Sand Blasting or by other means and then painted minimally using primer type of paint to make the material not easily rusty.

- The size and thickness of the construction parts shall be in accordance with the Scantling calculations of the rules for classification and contruction, for example as used for the classification and construction rules for Barge. - Scallop / Drainage hole on Bottom Girder and Bottom Transverse / Wrang not to miss its manufacture because its function is very important.

Sideboard

- Sideboard on Barge does not include the parts included in the ship classification, but its function as anchoring cargo is very important, especially in bulk type loading such as Coal, Sand, Iron Ore, Tanah Merah, Cement.

#Important parts of Sideboard are:

- Sideboard Plate; can use plain plate t = 8 mm (not special plate for ship).

- Sideboard Stiffener; the Elbow Iron material measures 125 x 75 x 8 mm or 100 x 100 x 10 mm.

- Stanchion; material from H Beam size 200 x 200 x 8 x 12 mm or 150 x 150 x 7 x 10 mm or made of plate t = 10 mm with triangular shape and flange.

- Support Stanchion; the same material as Stanchion.

- Sideboard door; rectangular door shape, the number of 3 pieces are arranged from bottom to top following Sideboard height and placed on left side, right and front side, material of 10 mm or 12 mm plate with amplifier from Elbow Iron 120 x 120 x 12 mm or 150 x 150 x 12 mm depending on the size of H Beam on Stanchion.

- Tug Push Pad; The construction consists of t = 10 mm or 12 mm plates with inner reinforcement of H Beam 150 x 150 x 7 x 10 mm. Tug Push Pad is the place for Tug Boat to push the Barge, when the barge is fully loaded, the draft will rise, the distance between the Deck and the water surface becomes small, if not provided Push Pad then when pushed (pusher) Barge then the bow of Tug Boat will come into contact with Sideboard that can cause damage to the Sideboard and spill the charge.

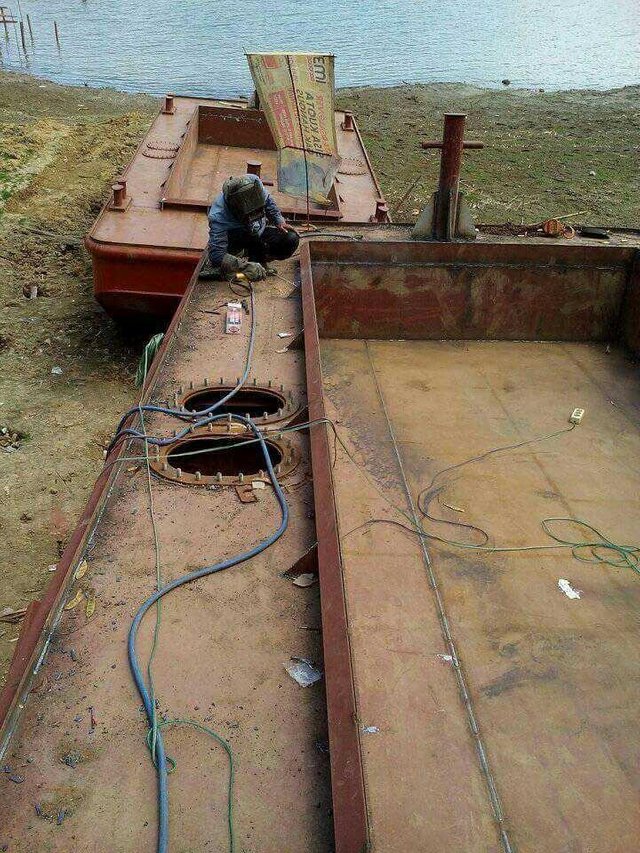

Manhole

Marine Plate / Special plates for ships - Mill Steel with Grade A.

How to make it: Manhole shape at the edges is half circle, Manhole consists of Cover and Ring with Bolt and Nut as Cover lock. After Cover and Ring are formed then both are united to the process of making a hole for Manhole Bolt by way of Drill / Drilling. After the bolt holes are formed Manhole Bolt inserted into the Ring and welded the ends so as to blend with the Ring plate. The next step is to place the Ring on the Plastered Deck first according to the size of the Manhole hole (600 x 400 mm). Bolt hole size on cover must be larger than Manhole Bolt diameter, in Manhole Cover usually given Handle to lift Manhole.

To keep the stability between Cover Manhole with Ring Manhole used Gasket or Rubber Packing with a thickness of 5 mm.

That is a tip And how to make a barge that I can convey, until Jumpa Back in my post @vanirfan the next may be useful and Thank you for having Learned About Ships.