Civil engineering -- #Earthwork

Hello steemains,

TODAY, i am going to share some of my knowledge about my core field i.e.., CIVIL engineering.

This is my second video today

So my today's topic is about #EARTHWORK

Here i will explain the various tests and its application on site work

1. In soil compaction test, if a test result exceeds 100%, should engineers accept the result?

Soil compaction is the process of increasing the soil density by reducing the volume of air within the soil mass.

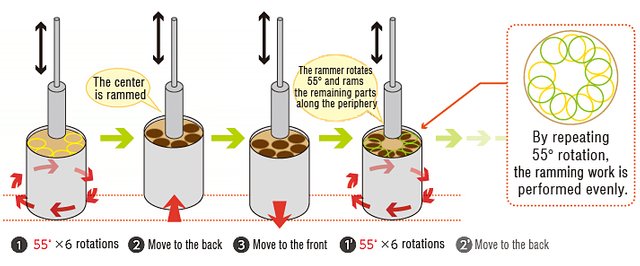

Soil compaction depends mainly on the degree of compaction and the amount of water present for lubrication. Normally 2.5kg rammers and 4.5kg rammers are available for compaction in laboratories and the maximum dry densities produced by these rammers cover the range of dry density obtained by in-situ compaction plant.

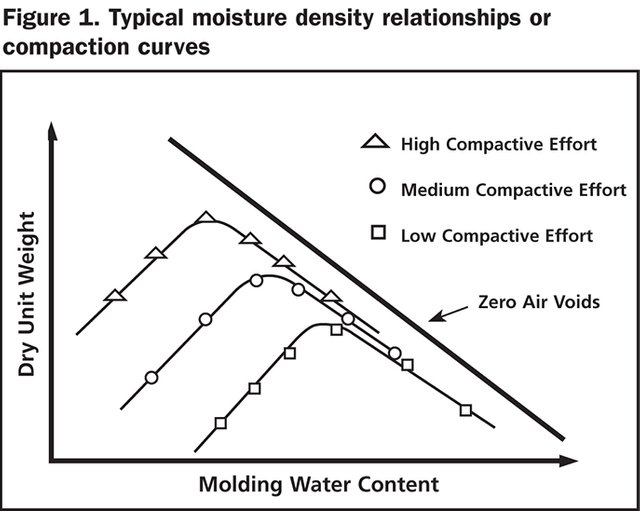

Regarding the second factor of water content, it affects the compaction in the following ways. In low water content, the soils are difficult to be compacted. When water content is increased gradually, water will lubricate the soils and this facilitates the compaction operation. However, at high water content, as an increasing proportion of soils is occupied by water, the dry density decreases with an increase in water content.

For soil compaction tests, the dry density obtained from compaction carried out in-situ by vibrating roller/vibrating plate is compared with the maximum dry density conducted in laboratories using 2.5kg rammer of compaction with similar soils. In essence, the in-situ compaction is compared with the compacting effort of using 2.5kg (or 4.5kg) rammer in laboratories. In case the compaction test results indicate values exceeding 100%, it only means that the in-situ compaction is more than that being carried out in laboratories which is treated as the basic criterion for satisfactory degree of soil compaction. Therefore, the soil results are acceptable in case compaction test results are over 100%. However, excessive compaction poses a risk of fracturing granular soils resulting in the reduction of soil strength parameters.

2. What are the different applications of draglines, backhoes and shovels?

An excavator is defined as a power-operated digging machine and it includes different types like shovels, draglines, clamshells, backhoes, etc.

A dragline possesses a long jib for digging and dumping and it is used for digging from grade line to great depths below ground. Its characteristic is that it does not possess positive digging action and lateral control of normal excavators. A dragline is normally deployed for bulk excavation.

A backhoe is designed primarily for excavation below ground and it is especially employed for trench excavation works. It digs by forcing the bucket into soils and pulling it towards the machine and it possesses the positive digging action and accurate lateral control.

A shovel is a machine that acts like a man’s digging action with a hand shovel and hence it is called a shovel. It digs by putting the bucket at the toe of excavation and pulling it up. Though a shovel has limited ability to dig below ground level, it is very efficient in digging above ground like digging an embankment.

3. For compaction of free-draining sands or gravels, what is the optimum moisture content to achieve maximum density?

The compaction curve of sandy materials is totally different from that of clayey materials. For sands or gravels, there are two situations of maximum density, namely the completely dry condition and the complete water saturation. For moisture content of sands and gravels between these two states, the dry density obtained is lower than that obtained in the above-mentioned states. The presence of capillary forces account for the difficulty of compaction sand at water contents between virtually dry and saturated state. They are formed in partially filled water void between soil particles and perform as elastic ties cementing soil particles together. Reference is made to Lars Forssblad (1981).

The compaction curve for clay is suitable for the majority of soil types except sands and gravels because a small amount of clay in soils is sufficient to make the soils impermeable.

4. Is it worthwhile to carry out tests on particle density of soil particles for geotechnical design?

Particle density of soils is defined by the ratio of soil particle mass and soil particle volume. Depending on soil types, the range of variation of soil particle density varies not significantly, i.e. by 4%. Therefore, it may not be worthwhile to order laboratory tests and incur additional expenditure just to determine the particles density by recognizing that the variation of particles density is not significant.

5. In determining the effective stress parameters of a soil sample, which test is preferable, consolidated undrained test or consolidated drained test?

The effective stress parameters of a soil sample can be obtained from both consolidated undrained test and consolidated drained test. However, consolidated undrained test is normally selected because of the following reasons:

Time taken for consolidated undrained test is shorter than that of consolidated drained test. It is because consolidated drained test requires the full dissipation of excess pore water pressure of the soil during testing and it takes long time when soils of low permeability are tested.

Useful information can be obtained from the stress path of consolidated undrained test. (iii)Failure occurs in lower stress level when compared with consolidated drained test.

6. In conducting triaxial test to determine shear strengths for soil samples, what consolidation pressures should be specified?

It appears that the selection of consolidation pressure is independent of in-situ soil stress theoretically. However, this may not be correct because the actual shear strength envelopes for soils are non-linear over a wide range of stresses. Therefore, consolidation pressure corresponding to the range of stresses relevant to site condition should be adopted.

7. What is the relation of bearing pressure on soil nail head to the ratio La/Lb, where La is the length of soil nail before the potential slip circle while Lb is the length of soil nail beyond the potential slip circle?

The unstable soil mass before the potential circular slip is resisted by two components:

Soil nail head bearing pressure and friction of soil nail in the unstable soil mass.

Therefore, the longer is the length of soil nail before potential slip circle La, the higher is the proportion of forces being resisted by frictional forces and hence the smaller amount is to be resisted by soil nail head. Hence, the smaller the ratio La/Lb, the greater is the resistance provided by soil nail head.

8. Soil nails are mainly designed for stabilization of major slips. How should designer cater for the stability of minor slips?

There are some methods to treat minor slips:

Adoption of smaller diameter size bars at closer spacing;

Installation of tie beams at the same horizontal levels;

Provision of steel wire meshes in-between soil nails; and

Provision of short soil nails in combination of long soil nails.

9. What are the main reasons for conducting pull-out tests for soil nails?

There are mainly four reasons for this test:

To check and verify the bond strength between soil and grout adopted during the design of soil nails. This is the main objective of conducting soil nail pull-out test.

To determine the bond strength between soil and grout for future design purpose. However, if this target is to be achieved, the test nails should be loaded to determine the ultimate soil/grout bond with a upper limit of 80% of ultimate tensile strength of steel bars.

To check if there is any slippage or creep occurrence.

To check the elastic and plastic deformations of test nails. This is observed during the repeated loading and unloading cycles of soil nails.

Note: Pull-out tests are carried out by applying specified forces in an attempt to pull out the constructed soil nails.

10. Are there any differences in the methods of compaction between clayey soil material and sandy material?

As suggested by Lars Forssblad (1981), the three main actions of compaction are static pressure, impact force and vibration. Different compactors contain one or more modes of these actions. For example, vibratory tampers perform mainly by the principle of impact

while vibratory rollers work with principle of static pressure and vibration.

For sandy soils, vibration is adequate for normal compaction because the action of vibration sets the soil particles in motion and friction forces between soil particles are virtually demolished. During this vibration motion, the soil particles rearrange themselves to develop a dense state.

For normal soils, it is necessary to combine the action of vibration together with static pressure to breakdown the cohesion forces between soil particles in order to allow for better compaction. The static pressure of vibratory machines is adopted to exert a shearing force to eliminate the cohesion in clayey soils.

This is all about earthwork in our civil engineering if i missed anything let me know in the comment section below.

Informative

thanks