I Hate Automotive Engineers

My Wife's 2011 Kia Soul needed a new battery, so I, as man of the house, volunteered to tackle this seemingly benign task and swap out the dying battery. I boasted that I could run over to the auto parts store, extract the old battery, replace and be home in under twenty minutes.

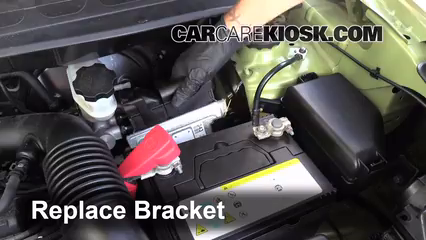

Every battery I've ever replaced was simply held in place by three or four clips which were easily accessed. Not the Kia Soul. These genius Korean Engineers couldn't make it that simple.

This battery's cradle was designed to prevent roving bands of battery thieves from considering the Soul as a target.

Behind the battery housing sits the onboard computer, which is as tall as the battery itself. Behind and below the computer are the two screws that have to be removed in order to free the mount that secures the battery. The screws are two inches long and the space allocated for wrenching them out is only good for about a quarter turn. Even with a socket with a swivel head it takes 47 quarter turns to remove each bolt.

The part that fries my whiskers is the fact that with each quarter turn of the socket, you have to be willing to cut yourself slightly, on another part of the engine. Make that same move 47 times and you end up with a nice wound.

Engineers should have to sit down with a group of mechanics before they design the layout under the hood and consider how their design will affect those that will eventually have to swap out the parts. No, instead they just randomly strap the parts in willy-nilly, leaving the home mechanic with festering wounds on their hands.

Thankfully I brought a small tool box with me to the auto parts store for my curbside mechanical work. I had already gone in the store and ordered the battery and some wipers and told them I would be right back with the swap battery. Twenty minutes later I returned for my purchase, sweaty, dirty and bleeding. Thankfully the clerk had enough pity to not make a comment.

Putting the battery housing back together was easier than the extraction, but accomplished in a steady shower. Life can be a real shit sandwich sometimes. I returned home to the misses over 40 minutes later than I had boasted I would, a wet - bloodied - dirty excuse of a man. She laughed in my face and asked when I was putting the new wipers on.

I went to the fridge and grabbed a beer. Wipers, stickem in your ear darling.

.png)

Wow, that would have pissed me off too. Geez. Well, at least you got a good story. I always say, but shouldn't, no job is complete until you bust a knuckle.

The busted knuckle is always inevitable when you start playing with tools.

Before graduating from engineering college, every student should become a member of the bloody knuckle club for at least a week. Their fingernails broken and greasy, their hands calloused. Then they will understand that just because it works on paper doesnt mean it works in real life.

Couldn't have said it better myself.

Couldn't have said it better myself.

When I was going to UTI back in 05', one of my teachers used to say the reason for all of these poor service designs is because the engineer came home and his wife was caught with a technician. It now seems to be a long running joke on the technicians. You wouldn't believe some of the things I deal with on a daily basis. Fords are by far are the worst for cutting your arms and hands.