Carbon fiber can be replaced by a new, less expensive material

By joining filaments of graphite to a fiber whose sheets had an extraordinary hardness and rigidity, carbon fiber was manufactured for the first time in history.

Developed by the engineers of the Royal Aircraft Establishment, in Farnborough, in 1963, this material has revolutionized various industries. However, carbon fiber is expensive. Something that could be corrected with this relief inspired by mother-of-pearl.

Inspiration in mother-of-pearl

The finding has been made by researchers at the Beihang and Texas universities in Dallas, who have developed carbon sheets of high strength and superhardness that can be manufactured inexpensively at low temperatures (the current carbon fiber compounds are expensive in part because carbon fibers are produced at extremely high temperatures).

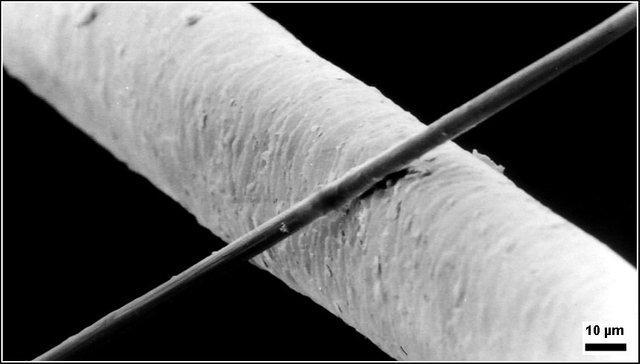

The team made the sheets by chemically joining the graphitic carbon platelets, which is similar to the graphite found in the soft lead of an ordinary pencil.

In addition, the mechanical properties of this new material surpass those of the carbon fiber composites currently used in various commercial products. It should be remembered that, in its day, carbon fiber was so miraculous that some science fiction fans even imagined that it could make the idea of building an orbital elevator with it.

According to Ray Baughman, Distinguished President Robert A. Welch in Chemistry at UT Dallas and director of the Alan G. MacDiarmid NanoTech Institute:

These sheets could eventually replace the expensive carbon fiber compounds that are used for everything from airplanes and car bodies to windmill blades and sports equipment.

The researchers found inspiration in natural nacre, which gives strength and resistance to some seashells.

Instead of mechanically stacking large-area graphene sheets, we oxidize micrometer-sized graphite plates so that they can be dispersed in water and then filter this dispersion to make inexpensive graphene oxide sheets. This process is similar to sheets of paper handmade by filtering a suspension of fibers. At this stage, the sheets are not strong or resistant, which means that they can not absorb much energy before they break. The trick we use is to join the platelets in these sheets using sequentially infiltrated bridge agents that interconnect neighboring superimposed platelets and convert the oxidized graphene oxide in graphene. The key to this breakthrough is that our bridge agents act separately through the formation of covalent chemical bonds and Van der Waals bonds.