Challenges in Developing Coatings for Military Aerospace: A Deep Dive

The development of coatings for military aerospace applications is a complex and demanding process. These coatings must meet rigorous performance standards while addressing various challenges that arise from the unique operating environments of military aircraft. Here’s a closer look at some of the key challenges faced in this field.

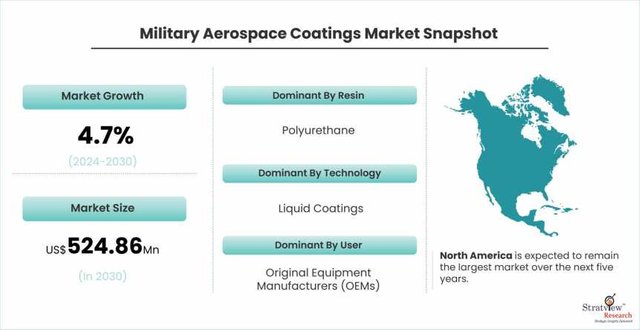

According to Stratview Research, the military aerospace coatings market was estimated at USD 380.55 million in 2023 and is likely to grow at a CAGR of 4.7% during 2024-2030 to reach USD 524.86 million in 2030.

1. Extreme Environmental Conditions

Military aerospace coatings are exposed to extreme conditions including high temperatures, corrosive environments, and intense UV radiation. These coatings must withstand these harsh environments without degrading, which requires advanced materials and technologies. Ensuring that coatings maintain their integrity under such conditions is a significant challenge.

2. Durability and Longevity

Given the high cost and operational demands of military aircraft, the coatings used must be extremely durable and long-lasting. They need to resist wear and tear from mechanical stress, environmental factors, and chemical exposure. Developing coatings that offer extended service life while maintaining performance is crucial for reducing maintenance costs and extending aircraft operational readiness.

3. Weight Constraints

In aerospace applications, every ounce matters. Coatings must be lightweight yet robust, as added weight can impact fuel efficiency and overall performance. Balancing durability with weight constraints requires innovative formulations and advanced materials, often involving a trade-off between performance and weight.

4. Stealth and Camouflage Requirements

Modern military aircraft often require coatings that contribute to stealth capabilities, such as radar-absorbing materials or those that reduce thermal signatures. Designing coatings that meet these requirements while also providing protection against environmental factors adds another layer of complexity to the development process.

5. Compliance with Regulations

The military aerospace sector is subject to stringent regulations and standards that govern coating materials and their application. Coatings must comply with various military specifications, environmental regulations, and safety standards. Navigating these requirements while ensuring that coatings meet performance criteria can be a daunting task for developers.

6. Cost and Manufacturing Challenges

High-performance coatings often involve expensive raw materials and complex manufacturing processes. Developing cost-effective solutions that do not compromise on quality is a persistent challenge. Manufacturers must optimize production methods to balance cost and performance without sacrificing reliability.

7. Innovation and Research

The aerospace industry continually evolves, pushing the boundaries of technology and performance. Coatings must keep pace with advancements in aircraft design and operational needs. Continuous research and innovation are essential to develop next-generation coatings that address emerging challenges and requirements.

In summary, developing coatings for military aerospace applications involves addressing a range of complex challenges. From withstanding extreme environmental conditions to meeting stealth requirements and managing costs, the process demands cutting-edge technologies and a deep understanding of both material science and aerospace engineering.