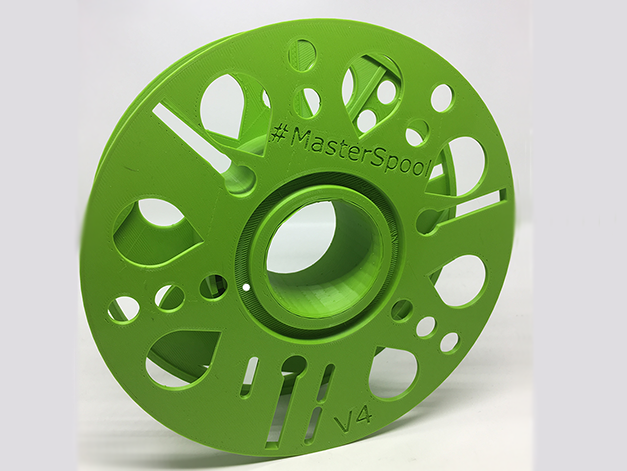

Testing the master spool for 3D printing filament

I tested the master spool for 3d printing last week. This new concept was invented by Richard Horne aka @RichRab3D.

The Idea

Instead of having a spool with each filament, you just buy the filament and put it on a master spool until it is empty.

Advantage

This will significantly reduce the waste produced when 3d printing.

I have quite a few of empty spools in my workshop.

They are waiting to be put to other use, but the master spool concept would have avoided this waste altogether.

The STL files for the master spool can be downloaded at Thingiverse.

It did fit comfortably into my print bed, but the spools are huge. You might end up with problems printing the spool on smaller print beds yourself.

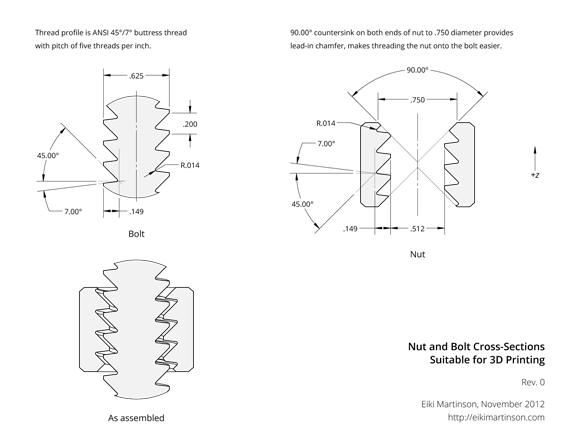

To speed up the printing process, I did use a layer height of 0.2. That probably wasn't the best idea as I noticed problems with overhangs in the screw cap mechanics.

Although it takes twice as long, I would next time take a layer height of 0.1 and wait for the 20+ hours. You probably can also prevent these issues when using a bigger nozzle.

But also with these small issues, the spool was fully functional.

Right now I only know DasFilament who are providing refill filament for the master spools. I hope more filament producers will support this system in the future.

I ordered a refill of Tom3D's Infinity Blue PLA. It did not yet arrive but I could test the spool with smaller filament coils that I collected for my small prints.

It worked very well, and I couldn't see any difference to other spools.

DasFilament also publishes a minimal version of the master spool ( Thingverse Download ).

I really was impressed with this simple design. It fulfills the same requirements as the huge master spool but uses way fewer resources. It is also of course easier to print.

The only downside here might be that you have not much room to put the sticker on it.

Now it's up to you! If your favorite filament vendor does not support master spools yet you should tell them about it! I'm sure there are advantages and price cuts for both sides that speak for this system. And after all, it will help to avoid unneeded waste!

Happy Printing

Dr. Make

Strange you had minor issues with those 45 degrees overhangs. The design is supposed to work also with 0.25 or 0.3 mm layer height.

May be a screw like this one may help a bit with the overhang:

http://eikimartinson.com/engineering/3dparts/

Very interesting side you linked there.

Ideas like these are what I love most about 3D printing and its community. Thanks for sharing your experiences, will definitely print one myself :)

Congratulations! This post has been upvoted by SteemMakers. We are a community based project that aims to support makers and DIYers on the blockchain in every way possible. Find out more about us on our website: www.steemmakers.com.

If you like our work, please consider upvoting this comment to support the growth of our community. Thank you.

Few years ago we could buy filament without spools. I always feel bad when I have to put empty spool to the bin. Plastic should be recycled but we never know if it will not go to landfill or burned in an incinerator. I would like to eliminate this waste. I hope this concept will become popular among filament producers.

BTW I follow Richrap, even almost built his mini delta printer. I failed in last step, calibrating it.

That's why I always keep them and plan to do build something from them (but never did so far). But I probably will use refill more often. Just got mine from DasFilament today and it literally takes seconds to put it on the master pool and it was cheaper then the PLA i normaly buy.

The price looks good and the colors are great too. Need to order some to try. Thanks for the tip.

You should take a look at recyclebot it makes 3d printing fillament from old HDPE.

I always thought about building a workspace ala https://preciousplastic.com/ and create my only filament :)