[3D Printing] What Price Teaching Special Needs With Tactile Words?

Nothing says love like your fingers in the right places.

A friend of mine that I've worked for in Disability Services at a major SciFi/media fandom convention for several years got in touch with me on Facebook recently to ask if I could help her out by printing some physical teaching elements.

Yes, yes – I know. Anyone that has been reading me on this platform for any period of time knows that I am not exactly what someone would refer to as warm and cuddly. In fact, to suggest that I am sociopathicly prickly and generally full of misanthropy probably falls well short of the truth.

"Why," a sensible person might ask, "is someone like that intentionally working with the disabled?"

Well, they're my people. Or as I like to put it, "cripples, freaks, and weirdos." There is something about being gravely physically disabled that makes one, despite the angels of your worse-er nature, generally sympathetic to those in a similar position. No matter your preferences.

So I have a history of working in DS, a well-known propensity to being involved with weird technical things, cheerfully own a 3D printer, and have some knowledge of the field.

I was the right guy to ask. You wouldn't think it, but it's true.

So why haven't I done it yet?

Pricing It Out

It's Just a Model

Mainly because I'm a huge slacker.

Honestly, I have no other excuse for not getting around to dealing with this for two weeks. That's totally on me. I'm a terrible person.

Luckily, I know I'm a terrible person.

Actually, there are some really good reasons that I haven't actually taking care of this myself, and it's instructive to have this discussion in public with other people who are interested in 3D modeling and 3D printing.

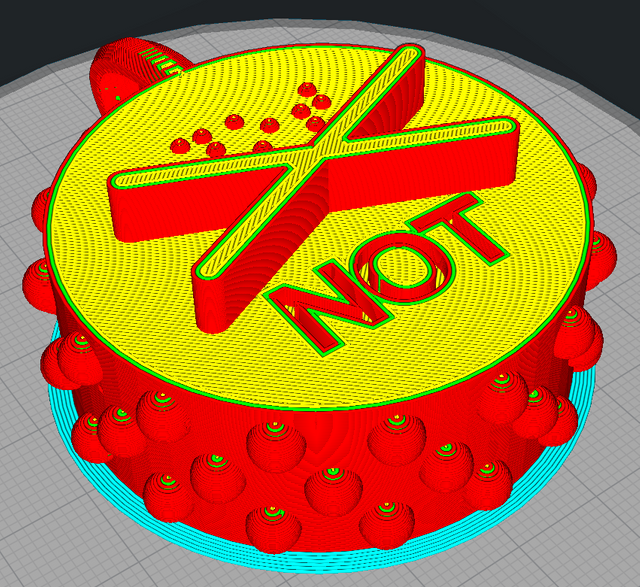

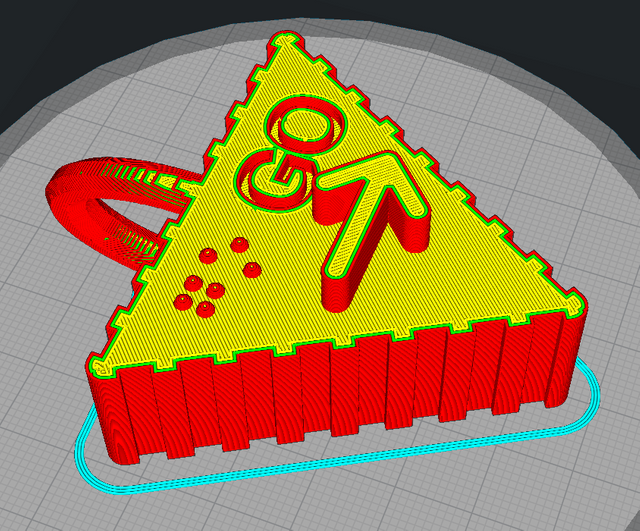

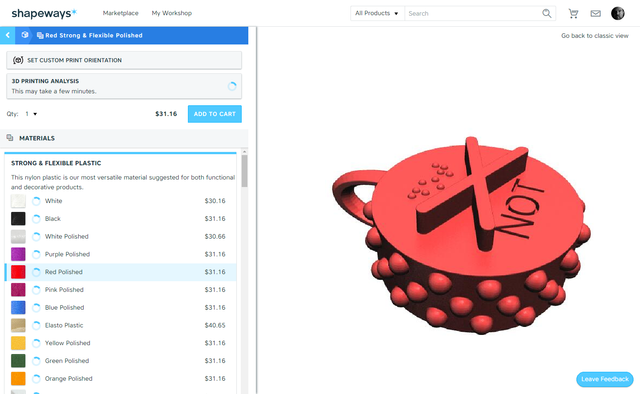

So let's take a look at the first of these models, the "Not" object. If you'd like, you can get these things for yourself from Project Core.

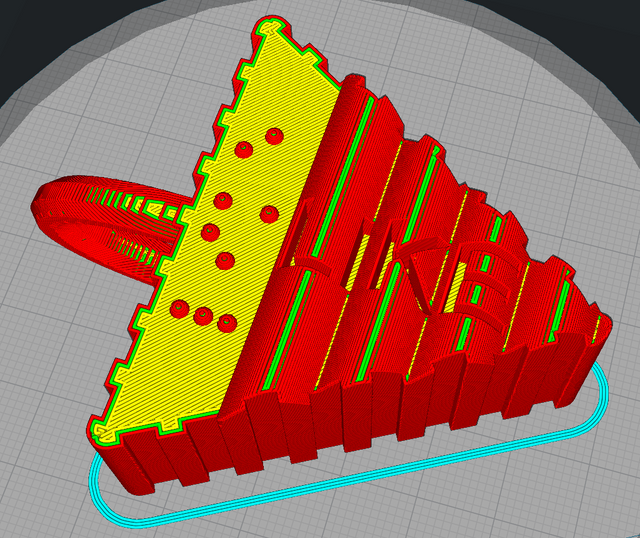

If you've got any experience with home desktop 3D printers, looking at the above model has already filled you with a sense of horror and foreboding. You're looking at those Dalek-like bumps to go around the outside (around the outside, around the outside) and you're wondering if even your favorite PLA has enough overhang tolerance to print them.

The answer is "no." Printing this on an FDM printer in almost any material is going to be a nightmare. You are going to have several hours of good, clean fun pulling off bits of support which will largely surround the entirety of the outside of this piece.

The top is okay. There's no beveling on the edges of that raised acts, so there's a good chance that they're going to be annoyingly sharp unless you hit them with a little bit of sanding, but the braille and text are incised enough to end up pretty clear. I haven't measured the width of the gap (yet), but it appears to be enough to be clear in a final print. Of course, if you are using material or your printer is simply prone to stringing, there is another half an hour or so with a small metal file cleaning out each letter.

Hades forfend that you want several of each piece in this set.

There are some people with really good desktop printers that laughing all the way to the bank right now, reading my complaints. They have no question that they could pull this off with a minimum of headache and cleanup would be a cinch.

They are liars.

Just so we're covering all the bases, even an SLA resin printer would have problems with the nodules on the side of this design – it's just that it would be hanging upside down rather than sitting on the bed.

From the point of view of a home 3D hobbyist, the best thing about this particular design is that it should have excellent bed adhesion with that big, flat surface. It probably doesn't even need the brim that I usually print things with and didn't bother removing before I captured this screenshot.

In the Hub-World

So printing these things at home, at least on the rather modest technology I have access to, is off the table. What do you check next?

One of the outstanding options is to let someone else who has a better quality of printer do it for you.

3D Hubs is one of the sites I go to if I want a nicely tuned professional print done by somebody local. i.materialise provides a similar service without the additional requirement or possibility of being local, most of the time. Either way, you're sending your model out to someone else to print it on their platform.

Most of the time you'll be working with someone who takes their work seriously, has quite a nice printer, and is essentially selling dead time on a business machine because it's a lot more useful and profitable to sell bespoke parts off of a printer than to let it sit idle. Even if it does induce more wear and tear, selling custom pieces can cover the expense of long-term maintenance for the main job, increasing the consistency of the gravy.

Of course, nothing in life is free.

You also need to keep in mind that most of the printers that are going to be available are, just like your desktop model, probably going to be FDM – which means things like the outer bumps on "Not" and the big vertical loops on both it and "Like" are going to require supports and a fair amount of cleanup. If you're paying someone else to make the part, at least they're the ones that are going to get stuck doing that work.

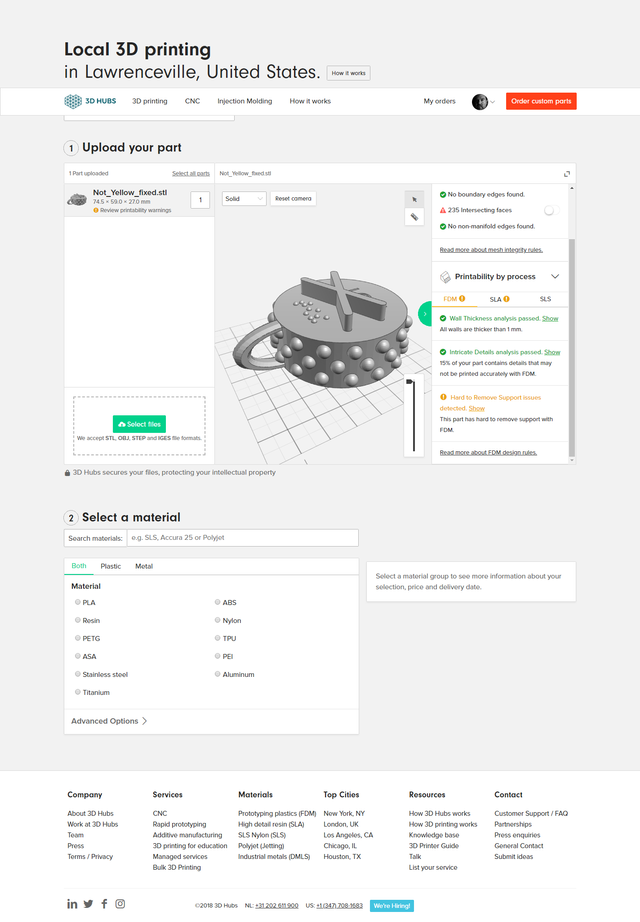

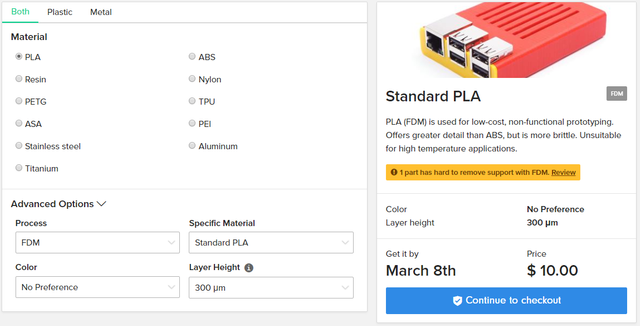

Let's run a quote on "Not" through 3D Hubs and see what kind of cost were talking about.

(No, I'm not terribly concerned about revealing my hometown. That's a secret so open that the fact Israel has nuclear weapons is looking at it going, "Yes, we knew that.")

You'll notice that the site is already recognized one of the problems that I pointed out, which is that the part will have really annoying to remove supports. This is true in both FDM and SLA, which is reassuring. It's always nice to have a machine tell you that you're right.

You'll notice that there is a third option, however. SLS.

SLS is a printing technology that essentially is a pit of fine granules of plastic with a bed underneath that can raise and lower. A laser traces out as single bottom layer and imparts enough heat to melt the granules, causing them to fuse. The bed lowers slightly, a wiper pushes more granules across the top, and the laser traces the next layer. Repeat until you have an all plastic model submerged inside a bunch of loose plastic granules. Raise it up, brush them off, and there you go.

It's a lovely technology. You can do some amazing things with it. But it's definitely industrial scale and getting your hands on one of those machines is not cheap.

Luckily we are going to use someone else's.

I know, I know. We could have this thing printed directly via metal deposition or binder jetting in stainless steel, aluminum, or titanium. Believe me, you don't want to know what those prices look like.

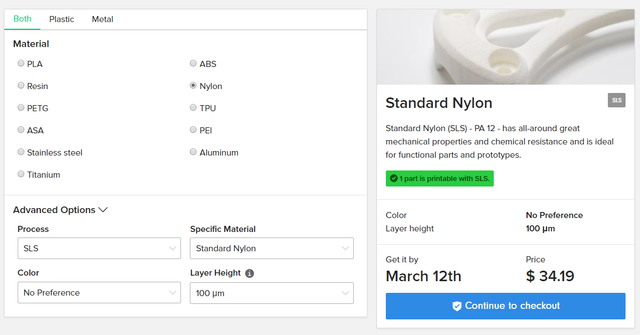

Let's just talk about nylon. It's a perfectly acceptable material. Strong, well wearing, comes in multiple colors if you really care, takes dye pretty readily – and is pretty much our only choice if you want to use SLS and avoid all the really annoying cleanup.

Via 3D Hubs, you're looking at a price for one of these of $35. That's not terrible for a bespoke, one-off part. It's a little more than 5 cm wide and a little over 2.5 cm tall at the highest point. It's a fair chunk of plastic.

However, if you are on a tight budget, this is probably not going to be your best bet.

Out of curiosity, let's see what this would run in the cheapest material I can think of available on 3DH, PLA.

$10, and you can have it by March 8. (I'm posting this on 5 March, in case posterity looks back on this post and wonders, "exactly how good is that response?")

This would be printed with a 0.3 mm layer height and the site is good enough to warn us that the model does have hard to remove supports.

Still, assuming you didn't get ripped by the printer for giving them something that required a lot of cleanup, this is a much more acceptable price point. The layer height is terrible, without question. I feel like that is a bad trade-off in general, but a three day turnaround from a company that probably is located near where I live? That might be acceptable.

We have other choices, though.

Immaterial Girl

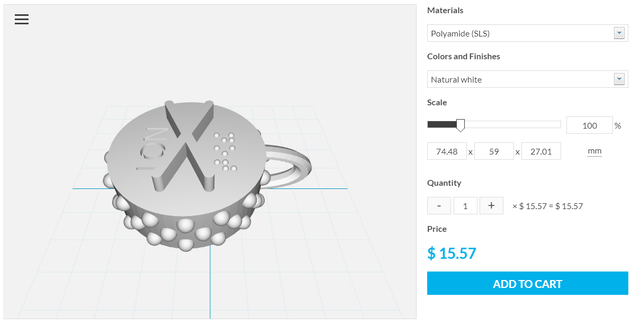

I.materialise often has different pricing than 3DH. Sometimes it's higher, sometimes it's lower, but it's usually different.

Being a completist sort, let's see what an SLS print from I.M would run.

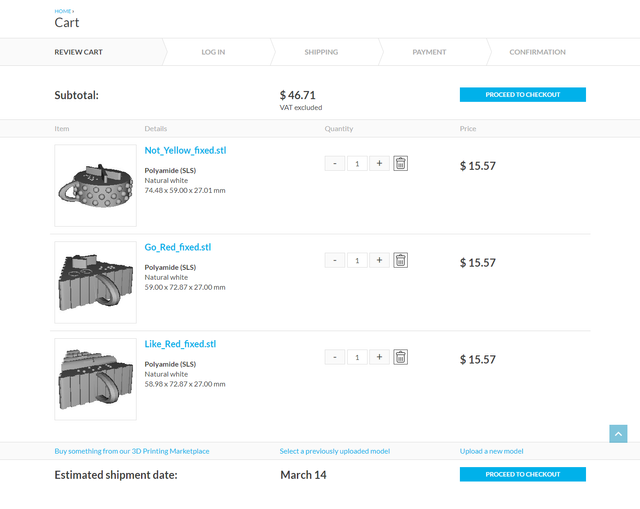

$15.57 for natural white is not a terrible price. The fact that it gives a convenient way to say I want more than one of these right there on the upload page is nice, but even nicer is the fact that ordering two of them would not be $31.14 but only $28.04 because of some discount or other.

Don't bother looking for a low-cost PLA or ABS FDM print on I.M because you won't find one. However, you could have one of these made out of silver for $1848.89. If you wanted. If you were so inclined.

$16 is a pretty decent price for one of these.

Can we do better?

Shapely Ways

I've been a big fan of Shapeways, in part because they were one of the earliest places that would do one-off parts, in part because they are one of the few places you can have an active storefront and sell the models that you have designed for a few dollars here and there, and in part because they just do a darn fine job.

But you pay for all of the above with both money and time. Uploading a new piece through their interface is not nearly as streamlined a process as either of the other two sites, but because it doubles as a storefront, more complexity is inevitable.

What wasn't necessarily inevitable was the price point.

The basic price for strong and flexible plastic there is $31.16, or $30.16 if we really don't care what color it comes in. Don't bother looking for the PLA FDM option, because while it exists, it will only save you five dollars.

Keep in mind that these prices are not marked up for resale. If I were going to price one of these to be sold through my storefront (which would be illegal since I don't own the intellectual property), there would be at least a $5 to $10 markup purely for my design work, and that would be generous.

Also generous is that SW will print one of these for you in platinum for the low, low price of $87,748.74. If you wanted it in solid platinum.

For the past year or so, SW has been pushing itself as the place to get 3D printed jewelry and high-resolution resin miniatures for gaming, and sliding away from the idea of being a place where one has larger, structural parts or pieces printed. That's a bit of a shame, if you ask me.

Full Damage

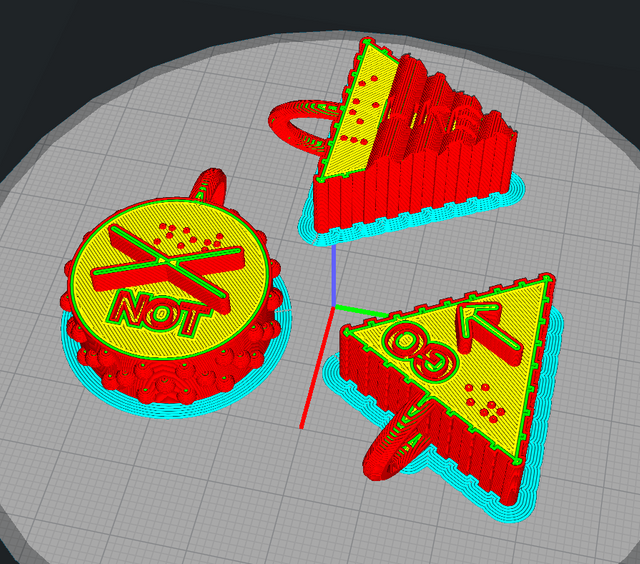

That puts i.materialise at the top of our relatively limited selection. Out of curiosity, let's just take a look at what they would charge us for printing a full set of all three pieces.

$46 for all three printed in nicely detailed SLS plastic is a pretty good deal. Shipping via USPS priority mail would only be an additional $4, bringing this in at just a little over $50 for a full set of teaching tools.

Honestly, while I'm not crazy about this price, I can certainly imagine it being a lot worse. We ran the numbers on options which would be a lot worse.

Unless you wanted this in platinum, in which case – that would just be exceedingly awesome, no matter how much it cost. I say go for the platinum.

But if you are a teacher at a school for children with special needs, platinum is probably out of your range. $50 per set for these these might be a different thing altogether.

If all of those are too rich for your blood or your looking to find a local organization which is likely to be willing to donate teaching tools to your local educational centers, it never hurts to reach out to your local maker spaces. Most of them have at least one and usually several 3D printers, members who would love a project to work on, and a Board of Directors which often craves really good PR opportunities.

That banner is from our local county maker space, Geekspace which you would expect me to be a member of – but the truth is that I just don't like other people enough to want to spend time in their physical proximity. That's not to say they don't have some very nice people.

I'm just not very nice people.

It might be worthwhile to reach out to them if you have no particular time pressure and want to keep involved with the local community. Everyone comes out looking pretty good in that situation.

Epilogue

Math is hard. Prices doubly so.

If you're looking to have some 3D models turned into really good pieces, your best bet is probably to shop those pieces around to some professional 3D printing guys. There are a number of online services that are willing to do so. In this case, I.M were the clear winners, but it's worth shopping around to all of them if you have the time.

The right tool for the right job.

Hopefully this little exercise in shopping was helpful or useful to someone who is looking for custom teaching tools. If you or someone you know is a teacher, convey to them my heartfelt apologies for having to deal with the little rug rats on a regular basis and my appreciation for keeping them locked up for several hours a day during some of the best parts of the year.

Being A SteemStem Member

3D movies needs different spectacles to see it and 3D art needs different angle to view it.

that was a far better read than I was expecting about 3d printing. The prices really are very reasonable. I was shopping around to have a piece of PET cut to an odd shape and the cheapest I could find was like $60 just to do the cutting

The costs of creating bespoke parts have dropped a lot over the last 5 to 10 years – largely driven by the increasing availability of 3D printers for reasonable prices and, more surprisingly and less often talked about, the availability of home and small business CNC machines. Once upon a time, getting a custom piece milled was a really complicated endeavor, from the complexity of designing something purely by descriptive drawing through finding a machinist capable of reading those drawings and turning out a reasonable piece. The whole process was expensive because each individual part was expensive.

Cheap and available 3D design software has made communicating purely by drawing a thing of the past, and we're all better for it. Desktop CNC designs have given the ability to enter the market as a machinist to a lot of people who never would have considered doing so simply because they would have never had the opportunity to try.

soon enough we will all have star trek replicators

Good contribution excellent friend work greetings ..!

Interesting post! I'll follow you!

To listen to the audio version of this article click on the play image.

Brought to you by @tts. If you find it useful please consider upvote this reply.

OK, @lextenebris -- you have got to make a sample ofr the first sentence of this post read by the TTS.

Madness! :P

Thants great! it will be easy to create lots of material by that..

Congratulations! This post has been upvoted by SteemMakers. We are a community based project that aims to support makers and DIYers on the blockchain in every way possible. Find out more about us on our website: www.steemmakers.com.

If you like our work, please consider upvoting this comment to support the growth of our community. Thank you.

3D printing looked so futuristic and promising at first, but it's kinda stuck, it hasn't become the 'build whatever you want at home' thing some thought it would. I wonder if it will become that in the future, or if some other innovation will replace it, like tiny bots flying around gathering material and building stuff, or whatnot.

I'm not sure that's entirely fair, if we're being honest. It's paid off exactly as much as it possibly could. We have desktop machines for under $200 that can produce any plastic physical object within pretty broad measure that you can tell it, describe it in terms that are sufficiently specific, and you can get whatever it is in under a day – sometimes under an hour.

That's a pretty big deal.

I think the problem is more that people remain uneducated about what the limitations of the basic technologies are, they want to believe things that are true, and they are essentially lazy. And they have no idea how things are actually done, which is perhaps one of the biggest problems.

Right now I can design a part that I need for fixing the leg of this microphone stand. I can specify it in my CAD software. I can print a prototype in the next room and see if it fits it looks right, and as importantly I can iterate on that prototype until it does. Then I can send that file, that one file, off to a printing service who will then turn it into a lovely piece of aluminum or stainless steel built exactly to my specifications and send it back to me.

Who needs tiny flying bots (which, point of order, is a technology which depends on a lot more magical imaginary tech than 3D printing) when I have FedEx?