Beneficiation Process and Characterization of Clayey Raw Minerals

"Beneficiation Process and Characterization of Clayey Raw Minerals"

Prior to utilization of clay minerals and other raw materials for manufacturing of ceramic products, they first undergo characterization. This is very important to determine their elemental analysis and mineral components in order to predict their effect and their outcome during and after firing of ceramic wares. Although this is not mandatory, it is still very essential to be more economical and to be able to produce good products if not the best. This could also help avoid uncertainties during the manufacturing process.

As a result of specific procedure in processing clayey raw materials and other ceramic raw materials, ceramic products can be economically made and industrially profitable. Thus initial determination of the properties of these raw materials are very vital as they could influence the outcome of the desired ceramic product. One of the most common raw materials which usually undergo characterizations is clay. Clayey raw materials have the huge impact in the final product. These clayey raw materials may also vary significantly even they are excavated at the same place.

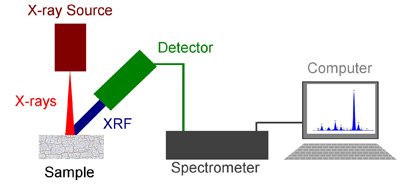

Technically, the application and the exploitation of clay minerals depend primarily on its structure, chemical composition and present mineral components. With the use of advance laboratory equipment such as X-ray Fluorescence or XRF, the elemental composition of clay minerals and other ceramic raw materials could be determined. The results would then allow ceramics engineers and ceramist to appropriately use it for certain ceramic product and predict its outcome.

However, since XRF analysis is expensive and that not all people can afford to conduct it, there are still alternative and simple analytical techniques and methods in order to determine the raw materials’ behavior without the help of its elemental analysis. These methods are also popular and are commonly used especially in schools and other small scale businesses. Also, the methodology only limits to determine its behavior and not its elemental analysis.

Right after the excavation of clay raw materials sample, a small amount of it (around 2-3 kilograms) is taken for analysis. These raw materials will undergo drying, pulverizing, screening and determination of physical and chemical properties through individual drying and firing. So first, the sample is dried in oven at 100 degrees Celsius to primarily remove its mechanical water. Others tend to increase drying temperature to 200 degrees Celsius but it is not economical. Once drying is done, the dried sample is pulverized using mortar and pestle or grinder.

Dried clay minerals are screened using 70 mesh screen. The term for treated ceramic raw materials is beneficiated clay minerals. The density of the unknown beneficiated clay sample is then determined using pycnometer. The pycnometer is filled with the powdered sample for about 1/3 of the pycnometer’s volume and then weighed. Water is then added inside the pycnometer to fill its volume. Simple calculation then follows to obtain its density.

Particle size distribution of the untreated or raw clay minerals should also be determined. The process is done by using various screens with different mesh size measurements. Although there are no standard screen sizes to be used for this process, then one can use anything available. The sample is subjected through wet sieving method. The sample is screened manually under running water over different screen size. Particles which failed to pass through individual screens are collected, dried, and weighed and are labeled as residue. Corresponding percent passed against sieve/screen size is plotted.

With these data, you can now partially characterize the unknown ceramic raw materials. Moreover, subsequent process and analysis could still be conducted. Individual clay minerals are formed into test bars by adding specific amount of water. Initial weight and dimensions of these test bars are then measured and recorded. Subsequently, air drying for 24 hours may or may not be practiced however it is essential as it could save energy. Then steady drying of these test bars then followed inside the oven at 100 to 200 degrees Celsius until constant weight is achieved.

After partial drying of test bars inside the oven, their weight and dimensions are again determined, measured and recorded. Dried test bars are then fired at desired temperature about 900 to 1000 degrees Celsius or depending on your desired temperature where you want to observe its individual properties and behavior. After drying, again the same parameters are determined and measured.

With these data, you can now make reports and discussion regarding the behavior and properties of the individual ceramic raw materials that you are planning to use for industrial manufacture of ceramic products. You can still proceed with other methods in order to determine other physical and chemical properties. Most crucial properties to be determined include density, particle size distribution, drying and firing shrinkage, water absorption, modulus of rupture, loss on ignition, vitrification, hardness and other properties that you want to determine based on your target product.

THANK YOU FOR TAKING THE TIME TO READ MY POST

Don't Miss This Year's Orionid Meteor Shower!

The Natural Occurrence of Clayey Raw Minerals

Diamonds Are Not Forever if We Understand its Nature and its Crystal Structure

Ceramics Water Filter for Safer and Healthier Drinking Water

Types of Portland Cement and its Individual Use in Construction

References:

1.) Characterization of Some Clay Deposits in South West Nigeria by Fatai Olufemi ARAMIDE, Kenneth Kanayo ALANEME, Peter Apata OLUBAMBI, and Joseph Olatunde BORODE

2.) Characterization of Clays in Odukpani, South Estern Nigeria, by V.N. Osabor, P.C. Okafor, K.A. Ibe and A.A. Ayi

How is XRF analysis expensive compared to the cheaper techniques? Is the difference so huge?

XRF analyzer costs between $20k to $50k, clearly small scale businesses wouldn't buy that just to analyze the elemental components of clay minerals. Hence, people tend to determine & observe its (clayey minerals) behavior and properties through those alternative methods.

Wow, that is totally way too expensive for most people I guess... We could be happy that other cheaper methods exist, even if they do not get to the same level of precision I guess.

Yeah, it does primarily depend on your purpose. XRF is mostly used for academic purposes hehehe btw, speaking of academics, please check out my recent post about my simple project during my college years :)

This post recieved an upvote from minnowpond. If you would like to recieve upvotes from minnowponds team on all your posts, simply FOLLOW @minnowpond.

It goes through a lot of process before finally being able to utilize the material. Information overload 😅

Hehe thanks Jie.

Characterization of a material is important to know the elements present and their respective concentration in percentage. It is usually done by getting a sample then analysing it through any process particular for the specific sample.

Yes, but even big industries do use XRF.

@cmtzco has voted on behalf of @minnowpond. If you would like to recieve upvotes from minnowponds team on all your posts, simply FOLLOW @minnowpond.

To receive an upvote send 0.25 SBD to @minnowpond with your posts url as the memo

To receive an reSteem send 0.75 SBD to @minnowpond with your posts url as the memo

To receive an upvote and a reSteem send 1.00SBD to @minnowpond with your posts url as the memo

Thanks for sharing.

You're welcome, glad you enjoyed it.