Do you know semiconductors? your answer is no... "I will explain to you very easily" Part # 5

Hello today I want to continue talking as usual of semiconductor compounds, last week I wrote a post about the technique of synthesis of Cu and In in a molten state through HORIZONTAL GRADIENT FREEZE, this time I want to show you another technique used in the laboratory of Laboratory of Structure and Engineering of Nanostructured Materials, which is called synthesis technique through Direct fusion.

This technique is widely used to grow and obtain ingots of semiconductor compounds applied to photovoltaic cells, its synthesis process is very viable and safe, since when adding the proportion of the elements to be united and after its later growth and obtaining the ingot perform tests to corroborate its chemical concentration of the element and normally the margin of error is always below 0.5%, ie its stoichiometry will always be as expected.

http://electronica.ugr.es/~amroldan/deyte/cap09.htm

However, in order to perform the synthesis of a semiconductor compound by means of direct melting, it is first necessary to construct a vertical furnace, which can be made with a ceramic tube refracted with aluminum oxide, this is done so that the compound at the moment of grow is maintained at the temperature required by us, because we know that the ceramic is very good insulation. Its size varies depending on the size of the samples you want to obtain but we in the laboratory construct one with an outside diameter of 6 cm, an inside diameter of 4.1 cm and a length of 58 cm.

Figure 1. Vertical furnace of an area.

This oven is connected to a temperature controller (figure 2). This function has the function of regulating the temperature by us manually, and in turn is connected to a voltage regulator (figure 3), it registers the maximum and minimum temperature points by medium of which we have established through a software that we design in the group of researchers in the laboratory.

Figue 2. Programmable Temperature Controller.

Figure 3. Adjustable voltage source.

The furnace can withstand an approximate temperature of 1500 ºC, to measure the temperature a chromel / cromel-alumel thermocouple was used.

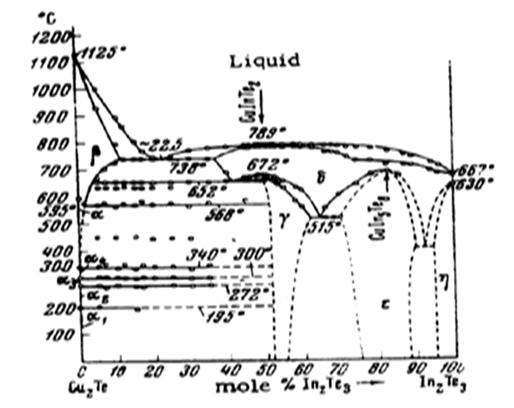

It is necessary to take into account that at the moment of making the growth of the elements we must first check which is the melting point of each one, for example, the melting point of the copper is of 1084ºC, the indian 155ºC and the telurio 449ºC. When we speak of melting point is to speak of the phase diagram that is translated in the changes of state that can present a material with respect to the temperature in the (figure 4) one can observe the phase diagram of CuInTe2, that is the material with which I am doing my undergraduate thesis.

Figure 4. Phase digram of CuInTe2 semiconductor compound.(1)

Then the stoichiometric calculations of the samples to be grown in the synthesis oven at high temperatures must be carried out, after which it must be cooled slowly and controlled to approach the points where it solidifies.

In order to obtain these ingots and grow them inside the oven, you must use quartz capsules, these have a cylindrical shape, rounded and transparent color, inside this capsule must be added the compounds to grow (figure 5).

To carry out its proper sealing first we must calculate the stoichiometry of the elements and then weigh them in an analytical digital balance, the sealing we perform in order to keep the elements that we are going to synthesize in a safe environment in a suitable environment so that they can grow correctly, avoiding that these elements can be damaged due to oxidation or other external agent that allows an undue result of the synthesis. For this, the sealing of the capsule is performed under vacuum, which is standardized in the laboratory in 3 x 10-6 Torr ≈ 4 x 10-5 Pa.

Figure 5. Quartz cap.(2)

It is important to take into account that in order to develop the synthesis program of the semiconductor compound it is necessary to take into consideration certain parameters like the temperature, the temperature that is needed to melt a certain element must be previously known and can be controlled by means of the program and the adjustable source of temperature. It is also necessary to position the oven horizontally for an interval of 10 minutes per hour in a total time of 24 hours, this is done in order to guarantee the homogeneity of the ingot

After completing the growth process, the quartz capsule should be removed and allowed to cool for 24 hours and then its due withdrawal from the capsule and you will have an ingot as shown in figure 6.

Figure 6. Lingot from the CuInTe.(3)

References:

(1) Marin, G. (2001). Preparation by different techniques, comparative studies of the optical and electrical properties as a function of the temperature of the semiconductors CuInTe2 and CuGaTe, Master's Thesis. Mérida, Universidad de los Andes, p. 5,6,7.

(2) Loaiza, A. (2014). Synthesis and physical chemical characterization of the semiconductor AgIn5,01Te8 .. Thesis presented in option to the academic title of master in Science and Technology of the Materials. Cabimas. University of Havana, Institute of Science and Technology of Havana, pages 24 and 25.

(3) Laguna, J. (2014). Synthesis and characterization of the compound CuInTe2 to be used as absorbent material. Thesis presented in option to the academic title of master in Science and Technology of the Materials. Cabimas. University of Havana, Institute of Science and Technology of Havana, pages 13 and 16.

If you want more information about semiconductor synthesis techniques I found this link very interesting:

http://electronica.ugr.es/~amroldan/deyte/cap09.htm

Future Physical

Thanks for the info! Upvoted your post but...

How do you think this message makes someone feel? Probably like shit.

I honestly did not understand the message of that user @ur-nxt-grlfrnd

I think it was, I couldn't be bothered to read your post.

I have reviewed the blog of that user @ur-nxt-grlfrnd and I think it is spam, it publishes nonsense information

Congratulations @carloserp-2000! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPThank you @steemitboard

Thank you for a very well done post, and thank you for the link. Have a nice day.

Thanks to you for having the kindness to read my publication and for your good comment, it is very encouraging for me and I am encouraged to go forward in this community.

Happy day for you too :)