" DESTILATION OF OILS ATSIRI FROM PANDANUS AMARYLLIFOLIUS ROXB "

Process of Essential Oil Distillation of PANDANUS AMARYLLIFOLIUS ROXB (Or The Like)

Pandan leaves is a single leaf sitting with the base of hugging stems and usually arranged three strands on a spiral stem. One characteristic of pandan leaves is to create a fragrant odor when squeezed squeeze. Pandan leaves are generally used as a spice that serves to give a green color to the food and also used to provide a fragrant aroma on the food that we often eat for fresh and fragrant.

According Rohmawati in his research (1995) showed that the chemical content of pandan wangi leaves is a bitter compound in the form of polyphenols, flavonoids, saponins, and alkaloids. Apparently another study by Jhonny (1991) also mentioned that the chemical content in pandanus fragrant leaves are alkaloids, saponins, flavonoids, tannins, and polyphenols. Chemical substances such as tannins, flavonoids, saponins, alkaloids, and polyphenols are secondary metabolites in plants that are antibacterial (Robinson, 1995). This is evidenced in several studies, that leaves ceplukan most of which contain polyphenols and flavonoids are able to inhibit the growth of bacteria Pseudomonas aeruginosa (Rianna, 2004).

In some studies show that the chemical content of pandanus fragrant leaves is a bitter compound in the form of polyphenols, flavonoids, saponins, and alkaloids. Apparently other studies also mentioned that the chemical content in pandanus fragrant leaves are alkaloids, saponins, flavonoids, tannins, and polyphenols. Chemical substances such as tannins, flavonoids, saponins, alkaloids, and polyphenols are secondary metabolites in plants that are antibacterial.

Operation and Maintenance of Flute

Preparation

Make sure to always wear gloves during the operation of the flute because all parts of the flute, water and plant material in it will be very hot.

Beware of steam heat, if necessary wear eye glass eye protection.

When using a gas stove heater, the operation of a distilled device shall be performed in an open space or room with adequate air ventilation.

Operation of the flute device should be done with good care and supervision.

Keep children away from the operating location of the flute tool.

Use of water for condenser needs

First choice

The water used can be directly from the tap water by connecting the ½ "water hose from the tap water to the water pipe entering the condenser. The weakness of this way: waste of water unless all waste water out of the condenser is recovered, which of course requires a large water container, while the advantage is the temperature of the water entering the condenser is stable.

Second choice

Reuse of water from the condenser repeatedly, using the submersible water pump and the 80-160 liter water container (plastic container / drum). Water is supplied with ½ "water hose to the condenser water pipe by the dye pump while the condenser discharged water is channeled back to the water container with ½ hose".

The advantages of this way: water savings and the operation of the flute can be done without having to close to the water source.

The drawback is: the water temperature in the tub will rise slowly after some time of heat change in the condenser, especially if the capacity of the water container is small. Water temperature is not cold cause condenser can not work efficiently.

The solution is: replace gradually some of the water in the baking basin that has started to heat or can also enter ice / ice water into the tub. If possible, collect plastic bottles from used drinks, fill water and freeze in the refrigerator, in order to be used to cool water in the tub.

It is recommended that you perform a test on a flute device prior to primary use, to see if there are any leaks or gaps in each welding section. Although this flute tool has been checked at the time of manufacture at the factory, but it needs to be tested again in case of damage during delivery.

How to test: put some clean water into the boiler, lock the boiler cover with the existing clip, attach the pole of the condenser with the tri-clamp and the gasket. Then place the flute on the gas stove / electric heater, then turn on the fire. When the water has boiled, pay attention and make sure there is no steam coming out of other parts except only in the distillate discharge pipes.

Operation

To start the distillation, fill 10 liters of water (as needed) into the boiler, insert the plant material into the plant material container, then place the container into the boiler. Then the boiler cover is locked with clip and attach the pole with tri-clamp with rubber gaskets.

Connect the water hose from the dye to the condenser water pipe while the water hose connected to the water pipe out of the condenser is directed to the water reservoir.

Put the flute on the gas stove / electric heater, then turn on the fire. Point the pipe out of distillate water to the oil separator. Adjust and adjust the position of each glass of essential oil container and container of water container hidrosol with oil separator.

No need to immediately turn on the water pump. Wait a while after the water approaches the boiling point, the new dye is turned on for the circulation of the water flow in the condenser. It usually takes about half an hour to wait for the water to boil, depending on the amount of water in the boiler and the amount of fire / heater provided.

Make sure the temperature of the distilled water coming out of the condenser between cold and lukewarm, if the water is distilled hot, then check whether the water flow in the condenser is smooth or the water supplied to the condenser is less cold.

When the quality of the distillate water decreases or when about 80% of the distilled water has been taken, the fire / heater can be switched off and the flute is allowed to cool.

It is preferable that the glass of essential oil container be separated between the mid-distillation and the mid-late distillation, since it is usually near the end of the distillate, the distilled water coming out is not as good as initially because the essential oil has been extruded out.

Remember, if the distilled water has collected 80% of the boiled water, it means the distillation can be stopped, so that the boiler should not be dry. It should be noted to never heat the boiler dry or without enough water.

The distillation usually takes 2 to 4 hours, depending on the water and the distilled plant material.

The pandanus fragrant leaf extract produced by the extraction process using n-hexane solvent contains 15 types of compounds consisting of alkane group compounds, alcohols, ketones, carboxylic acids, esters, and terpenes. The resulting pandanus fragrant leaf extract has not met the criteria for aromatherapy ingredients because it still smells of solvent, mixed with other compounds such as wax, pigment and semi-solid form so it still needs to be improved process to improve its quality. The method to be carried out is the process of extraction with n-hexane solvent followed by re-extraction using ethanol solvent. With the re-extraction process is produced a good quality pandanus fragrant leaf oil that is more pure, not mixed with other compounds, without the smell of solvent, liquid consistency.

The essential oil produced needs to be tested for its chemical composition to determine its suitability to the spa requirement. This study aims to determine the differences in chemical composition of the compound compound absolute essential oil of pandanus fragrant leaf on the re-extraction treatment with ethanol.

Absolute essential oil of fragrant pandan leaves composed of alkana group compounds,

alkene, benzene, alcohol, phenol, terpen, and esters with different relative concentrations in each treatment. The treatment of concrete and ethanol comparisons in the re-extraction process influences the dissolution of aroma compounds in concrete into alcohols. There is a tendency for more ethanol to be used in the process of re-extraction of more terpen compounds and esters (compounds that have a share in the aroma) that contain absolute pandanus fragrant leaves. This is related to the effectiveness of the extraction process increases with increasing amount of solvent

Thank you friends who have read my third article.

Regards @steemstem

Greetings to all of us

@maulizar

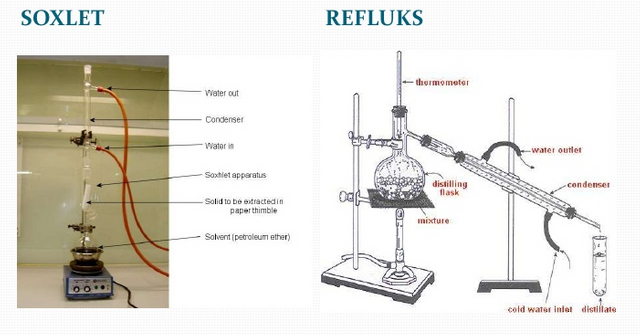

Good article! Do you think there is any difference in the method of extraction? either by Sohxlet or distillation by steam drag?