Drilling fluid for an oil well is like blood for humans

Introduction

In this publication I will touch on certain technical aspects and reflections that highlight the importance of using a good drilling fluid in the drilling and construction of an oil well. We petroleum engineers are the doctors in charge of giving the best operational practices in the construction of a well, if the well symptomatically presents an anomaly almost always the place to go and check if something is wrong is in the drilling fluid, it is As when a person goes to the doctor and describes a series of symptoms, the most likely thing is that something in his blood goes badly, then the doctor sends him to do a series of medical tests to evaluate certain chemical aspects in the composition of the blood for rule out whether you have high cholesterol, high or low blood glucose, if suddenly the platelets have gone down a bit, check how the hemoglobin is. In the same way when something in the hole drilling is wrong, I am an engineer in particular, the first thing I do is think about the drilling fluid, so the first thing I do while in the drill is to send a test to the drilling fluid, in this laboratory test you measure its density, viscosity, yield point, filtering and other series of elements that will help determine if the problem with the drilling has to do with the drilling fluid, is that is why I say in the title of the article that drilling fluid in a well is like blood for humans.

Now to try to understand why drilling fluid is so important in the drilling of a well, it is necessary to conceptualize what a drilling fluid is, also called in the oil industry as drilling mud.

What is a drilling fluid?

A drilling fluid is a fluid with special characteristics, used in the drilling of an oil well to fulfill a series of functions that facilitate the drilling and construction of a well. In the oil industry it is also called drilling mud, since its emulsifying characteristics make it have the shape of mud, there are many additives that are added to prepare this mixture, but always use fixed bases on which the fluid is manufactured final.

Types of drilling fluids

Oil based fluids: this type of fluid uses diesel oil as the main fluid, that is to say diesel is the base of the construction, to this base are added chemical additives such as bentonite, emulsifiers and other additives to control the properties of the fluid such as density, viscosity, filtering, properties of the gels, among others. This fluid from my field experience, I can say that in the field, the ceiba, barúa and motatán when drilling deep wells of approximately 16,000 feet deep, we generally use oil-based fluids from the intermediate hole, that is more or less the 5000 feet of depth, since at this depth there is no danger of surface water aquifers being contaminated, the other reason is that from this depth there are shales, which swell with water and can be stuck the pipe, so it is advisable to use an oil base fluid.

Water-based fluid: This fluid uses water as a base fluid, in addition to other chemical additives such as gelling agents, clay, and other chemicals that help the temperature in the bottom do not evaporate the liquid phase . As I mentioned in the oil base fluid, in my work area this fluid is used as water gel from the surface up to 1000 feet deep, then to this water gel other additives are added to continue drilling up to 5000 feet approximately.

It should be mentioned that there are many more drilling fluids, some fit within the classification of fluids on balance, as is the case of water base and oil base, others are drill fluids under balance.

To understand this part I must say that the pressures that are handled in the drilling of a well are very important, since even the handling of pressures depends on the safety of the location where it is drilled. In the reservoir, that is to say in the reservoir rock where the oil and natural gas are located, there are very high pressures, sometimes a lot of that gas migrates to the surface, all these reasons make it necessary to drill in a controlled way, that is to find the environment conducive to formation fluids (oil + gas) do not enter the well and reach the surface, this can cause an attack and a possible blowout. For this it is advisable to drill under the technique of over balance with fluids or sludges in water base and / or oil base, the important thing of this is to understand that the hydrostatic and circulation pressure that the drilling fluid has to exert in the construction of all the hole is greater than the pressure of the formation fluids (oil and gas), this condition is known as perforation on balance. In particular, in my experience, all the drilling in which I have been present have been on balance, with the exception of one exploratory well where I wanted to evaluate its productivity, and because its lithology was leveraged we drilled it in low balance.

In the underbalanced condition the opposite happens, the hydrostatic and circulation pressure exerted by the drilling fluid must be less than that of the formation, thus being able to have an oil and gas production while drilling, for this technique it is necessary have a series of superficial control equipment for any eventuality.

Finally it was time to enter the functions of drilling fluids, since with the description and understanding of these functions we can understand the importance of the use of fluids in the drilling and construction of a well.

Functions of drilling fluids

There are many specific functions, but in reality the function by which one began to think in ancient times of using drilling fluids is to be able to remove the cuts generated by drilling, once the rotary drilling has been used and replaced by drilling. to percussion where there was no control of the perforation by using some drilling fluid. As it has been presented some needs in the problems presented by the drilling has been adding new chemical additives to the drilling fluid, so that its gamma of functions is expanding more and more. I will explain in detail the following functions:

1. Cool and lubricate the bit (wick) and the drill string.

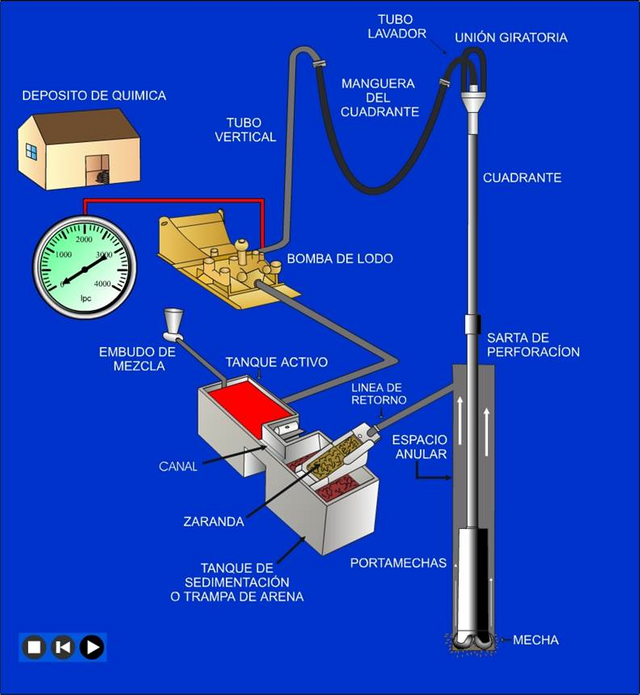

Once the rotary drilling technique was already in place, that element was needed to cool the cutting element of the drilling, that is to say when drilling there is something called drill bit or drill bit in order to cut the formation to deepen as tubes (drillstring) are introduced and also to be able to lubricate while drilling, otherwise if the fluid is not used the perforation will stop, since the trimming will accumulate around the wick and the drill string without this can continue spinning and cutting the formation. The heat generated by the friction of the cuts would cause the components to wear out, so the power to cool and lubricate the components of the string including the wick is of vital importance.

two. Cleaning at the bottom of the hole.

As mentioned in the first function, it is necessary that the cuts generated by the wick be transported from the bottom of the hole to the surface, for this there must be the necessary hydraulic power, once the drilling fluid has been designed for the well phase, It is necessary to design a configuration of the wick jets, the flow rate, the pumping pressures, all this interferes with the cleaning of the hole, with the drilling fluid being the protagonist of the event.

3. Control of bottom pressures

At the beginning of the article I mentioned it, there has to be a control of pressures in the construction of the well, that is to say, the drilling fluid has to provide pressure so that the formation fluids do not invade the well and reach formation, yes that pressure It has to reach a balance, if the perforation is on balance, it must have a fluid whose density is able to maintain a hydrostatic pressure and circulation above the reservoir pressure, but always bearing in mind that the fracture pressure of the formation, because if this happens all the drilling fluid that will go through the fractured formation will be lost, thus losing pressure of the drilling fluid, causing operational problems in the drilling, we can say then that the drilling fluid can have the ability to control the pressures of the fund according to the requirement, if it is on balance or under balance.

4. Create a plaster on the walls of the hole.

This is a very important function because as it is drilled and depending on a property called filtering, the fluid creates a film or plaster on the walls of the well that helps it to stay firm and the well does not collapse. The property of the filtrate has to be controlled, since a very high filtering implies that the plaster is very thick and there is a small invasion of solid particles of the fluid that in the future can alter the productivity of the deposit, if the filtering is very low I mean that the plaster is very thin and the walls of the hole can collapse, bringing this multiple problems, among the most important is the glue of the drill pipe.

Conclusions

As good well doctors, we have to know how to interpret the problems in the construction of the well, examining a sample of drilling fluid every certain interval of the drilling, that will cure us of ills. For example, if we find that when we turn off the mud pumps, the well flows only because the fluids are entering the formation, the most probable is that the density is below the programmed, it is advisable to control the well with the shock of the valves to remove that pressure and gradually incorporate solid and fluid base drilling fluid until the density increases to the density according to schedule. If there is a pipe stick, there may be problems with the cleaning of the hole, then it is advisable to have the sludge tested to rule out that the problem is filtered, or that the gelling of the mud is failing and the cuts in suspension when the Pumps are paid this failing and that cuts cover the wick. Finally, every problem in the drilling is almost always associated with one of the functions that the fluid has and the most advisable, is to attack in correcting the function of the fluid that is failing, for this it is advisable to monitor the laboratory tests on site , that is to say in the drill, and later with more calm they can be sent to carry out special tests where a sample of fluid is taken out and sent out of the drill.

Note: All the description of this article is based on the knowledge acquired in the academy and my experience as an engineer in oil industry drilling operations, any questions or questions I would like you to make in the comments , I hope that this publication is of the taste of all those who like the matter of drilling wells, greetings to all.

Congratulations @uzcateguiazambra! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click here to view your Board of Honor

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard:

Congratulations @uzcateguiazambra! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click here to view your Board

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard:

Congratulations @uzcateguiazambra! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!