Robot blade servicing in semicon industry

Friday was not a good day, because there is a scheduled maintenance on one of the machine. A tough one- that is to change the robot blade bearing.

A robot blade is looks like this:

It's basically transferring the wafers from one chamber to another or to loadlock to transfer out.

So the main character is this robot blade:

You will have to lock up the robot movement first, then dismantle from assembly using the jig.

A dismantled robot blade look like this. After taking out the cover, then you see inside there is bearing for movement rotation. And a small spring to latch both gear together.

The job of changing the bearing itself is not that tough, but the aftermath is the key toughness

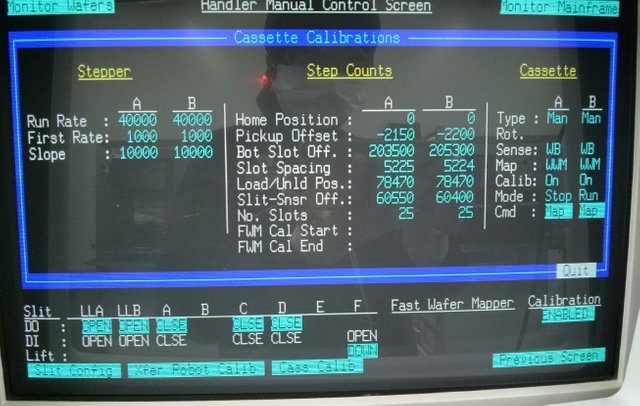

You will have to calibrate and teach the robot the correct setting into the machine configuration.

You have to use checking tools to make sure the robot blade is levelled always and not tilted up or down to scratch the production wafers. Once scratches then there gone our annual bonus..

So the best strategy is getting another technician over to help you command the robot, and one is focus in checking the robot alignment. Better to be safe than sorry !