Description of the construction and completion of the Franquera-21X well // Applying Engineering Technical details

Another very important point in the construction of the well, is the description of the operational procedures carried out during its construction, in the operational activities carried out in its construction, not all are carried out in the same way, since each phase of the well carries intrinsic certain characteristics that define what is different in the operational part of each one. That is why the part of the operational activities in the phases of the construction of the holes will be described:

- 26 "driver.

- Surface 17-1 / 2 "

- Intermediate 12-1 / 4 "

- 8-1 / 2 "production

- Completion and cannonade

For the considerations that can be taken in the construction of neighboring wells it is necessary to make certain graphs and curves to be subsequently filed, which will even allow us to compare the parameters that were predicted in the well construction program and the deviations obtained in function of the results obtained:

- Depth vs. density curve.

- Pierceable curve.

- Detailed times by phase.

- Details of productive and unproductive times by phase.

- Detailed costs by phase.

- Trajectory of the well.

- Mechanical diagram of the well.

Theoretical bases on which the article is based.

Design in well drilling.

The design of the drilling of a well is a systematic and orderly process, which requires that some aspects be determined before others. For example, the prediction of fracture pressure requires that the formation pressure be determined previously.

The stages to follow during the design of wells are well identified and are the following:

- Compilation of available information.

- Prediction of training pressure and fracture.

- Determination of the settlement depth of the coating pipes.

- Selection of well geometry and trajectory.

- Drilling fluid program.

- Program of augers.

- Design of coating pipes and cementation program.

- Design of the drill string.

- Hydraulic program.

- Estimated drilling times.

- Drilling costs.

It should be noted that for the construction of the franking well - 21X, its design was based on the development of a general drilling program, carried out by design engineers, taking into account all the considerations mentioned above.

This design process can be applied in general to any well, whose only requirement is to apply the appropriate technology for each stage, it also requires the integration of engineering, safety, ecology, minimum cost and utility.

Objective to drill an oil well.

The objective of drilling an oil well is to build a means of communication between the deposit and the surface facilities to take that oil to its commercial destination. The exploitation of hydrocarbons must be carried out safely and at the lowest possible cost.

Coordinates and objectives of the driver hole.

One way to accurately position a point on the earth is by using U.T.M (Universal Transversal Mercator) coordinates, which are universal and refer to a certain conical projection of the earth.

To drill a well, one or more points are required to locate the trajectory that a well must follow. A coordinate will indicate the position from which the drilling begins, and another that will indicate the point at which the objective is located, defining if the well can be built vertically or directionally. However, it is possible for a well to be drilled to achieve more than one objective.

Total depth programmed.

It is the vertical depth at which the target is located, but when a well is not drilled vertically, then there is a depth called total depth developed that is greater than the total vertical depth.

According to the vertical depth reached, the wells are classified as:

- Deep (between 15 thousand to 20 thousand feet).

- Ultra Deep (Wells greater than 20 thousand feet deep)

There are other theoretical considerations that further support the realization of this article, although take into account the aspects mentioned above, so as to make a theoretical summary and not make the publication as extensive.

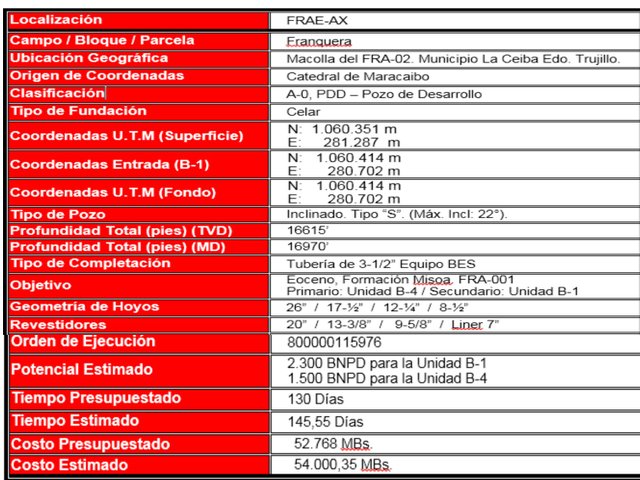

Construction of the fra-21X well (General well information)

Source of graphics: Carlos Balzán 2012.

Geological and reservoir considerations of the fra-21X well

Objective.

The fra-21X well is proposed as an inclined well with the purpose of adding a drainage point that is required for the development of the "B-4 FRA-0001" deposit; of the Misoa formation. The estimated production potential of the Fra-21X well is 1,500 BNPD for Unit B-4 and 2,300 BNPD for Unit B-1, both by natural flow.

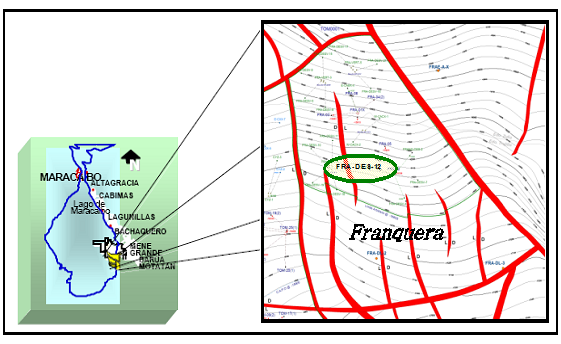

Geological information, location and target coordinates

The "B-4 FRA-0001" deposit is located southeast of the Ceuta Sureste-Tomoporo subdivision, east of the coast of Lake Maracaibo. The location FRA-DESV-12, is located on the surface in the tiller of the FRA-02 well, while the geological objectives will be reached through a trajectory inclined towards the west of it.

Author of the image: @carlos84. Graph that represents the exact location of the Fra-Desv-12 location where the Fra-21X well is located.

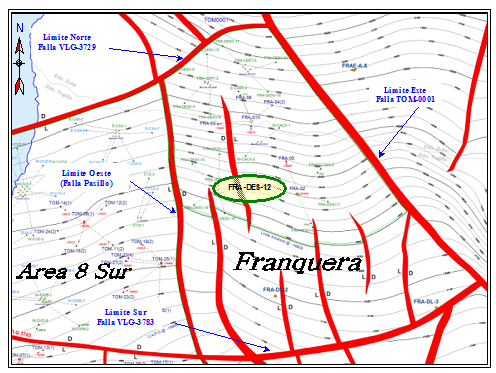

The location FRA-DESV-12 is located in a diving homoclinal approximate of 5 ° to the south. Said block is crossed by a set of minor faults of the normal type in preferential direction N-S. The structure is interpreted as a continuation corresponding to the yac. Eocene B-Superior VLG-3729. It is limited to the north, by the normal fault VLG-3729 with direction SO-NE and dip towards the northwest; to the south it limits with the normal fault with direction O-E and dip towards the north, denominated fault VLG-3783. To the west with a normal fault called "Falla Hall 1", which goes east. The east limit is constituted by a normal fault and dip to the east, called TOM-1X fault. The Loc. FRA-DESV-12 is located in the central part of the Franquera area (tiller well FRA-02). Structurally the loc. It is about 30 'lower than the FRA-02 well at the level of Unit B-1, while at the level of Unit B-4, it is about 60' lower than its neighbor FRA-02.

Author of the image: @carlos 84. Image representing the structural map of the top of the sand whose deposit is Unit B-04 (Field B-01 FRA-0001).

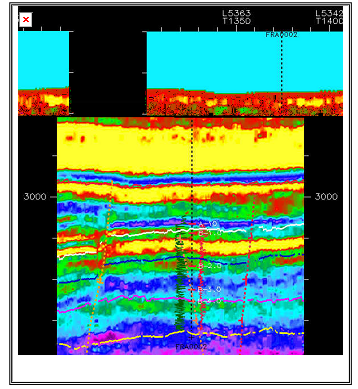

The figure shown below shows a seismic line in the O-E direction, where the interpreted geological markers are observed and whose dip varies between 4 to 6 ° in a southerly direction. Both regionally and locally, there is good preservation of the strata, which show good lateral continuity towards the location FRA-DESV-12. According to the seismic information, there are no appreciable geological risks that may affect the proposed trajectory, because the location at the level of Unit B-4 is 570 meters east of the nearest fault.

Author of the image: @carlos84. Represents the seismic section part SO - NE. Location FRA-DESV-12 where the fra-21x well was drilled.

Geological forecast of the well.

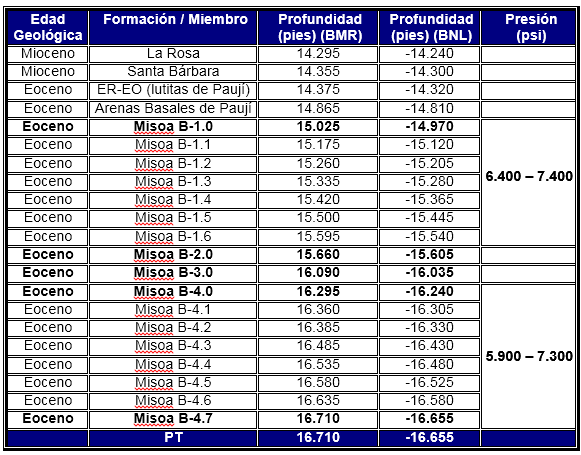

The following table shows the location FRA-DESV-12 with the limits of the estimated intervals to be drilled in the stratigraphic sequence.

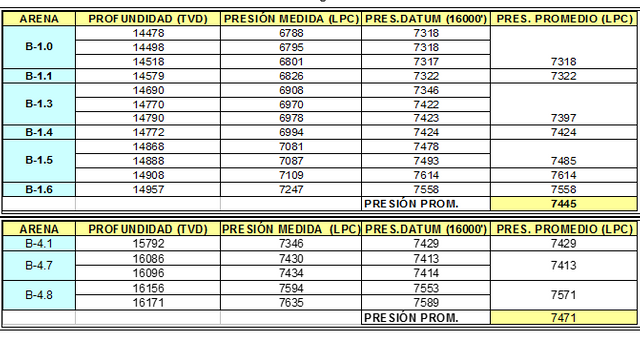

During drilling of the FRA-1X well, a "Formation Tester" log was run that revealed the original reservoir pressures of units B-1 and B-4, as shown in the following table:

Author of the table: @carlos84. Which represents the pressures recorded in the FRA-1X well.

The pressures recorded by the "Training Tester" were corroborated with those obtained during the DST tests. At the level of the B-4 unit, the DST test showed a bottom pressure of 7360 psi while at the B-1 level it showed a pressure of 7372 psi.

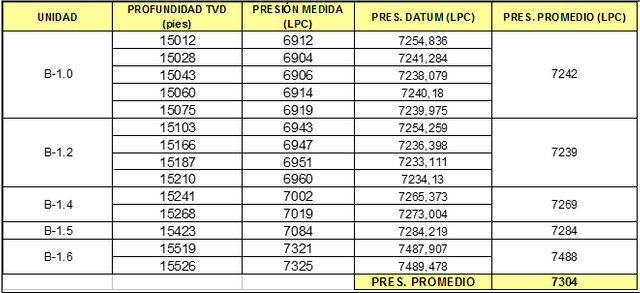

Additionally, during the drilling of the FRA-02 well, a "Training Tester" record was run, the results are shown in the following tables:

Author of the table: @carlos84. The table represents the pressures recorded in the FRA-02 well of the Miosa B-01 reservoir unit.

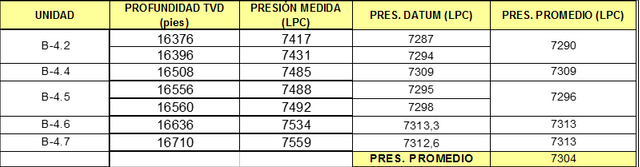

Author of the chart graph: @carlos84. The chart represents the pressures recorded in the FRA-02 well of the B-04 unit.

When comparing the original pressures with the pressures recorded in the FRA-02 well, a small energetic decline could be observed at the B-1 level, a condition that would have to be expected due to the drainage of fluids originated in the FRA-1X well. On the other hand, at Unit B-4 level, there is also a slight decrease in pressure, a situation that represents a point of attention if it is taken into account that there was no well draining this unit at the time of registration. The only drainage that this unit had suffered was represented by the DST test carried out in the FRA-1X well. However, the reservoir pressure estimated by means of the pressure restoration test indicates a pressure at B-4 of 7477 psi very close to the original pressure. In unit B-1 the pressure obtained from the interpretation of the restoration test was 7247 lpc and was corroborated with the average pressure value measured with the RCI which was 7304lpc.

Temperatures recorded in wells neighboring FRA-21X.

The temperature readings obtained for Well FRA-10 in the production hole vary between 245 ° F and 292 ° F, which are close to the temperature values shown by the neighboring wells.

Operational activity.

Drilling the 26 "conductor hole // Cement Conductor 20".

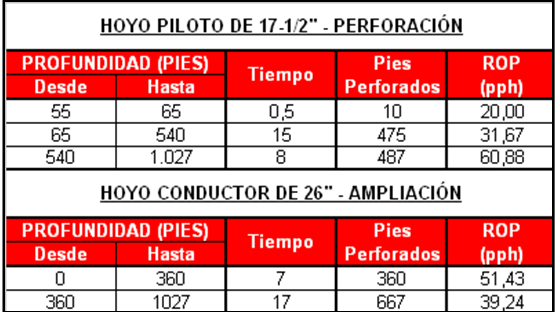

The drilling of this hole was carried out in two stages, first a pilot hole was drilled using tricone wick of 17-1 / 2 "from 'to 1027' and then extended to 26" to the depth of 1027 ', with the following parameters : GPM: 100-700 Gal / min, RPM: 80 -120 and PSM: from 0 to 10 Klbs.

The fluid used was water gel mud with a range of densities between 8.6-9.3 lpg.

This section was covered with 20 "coater, 94 # / Foot, K-55, Big Omega thread up to 1025 ', no problems. The cementation was carried out with an oil cement slurry H, with a density of 15.6 Lpg.

Author of the chart graph: @carlos84. Which represents the drilling rate of the 17-1 / 2 "and 26" driver hole.

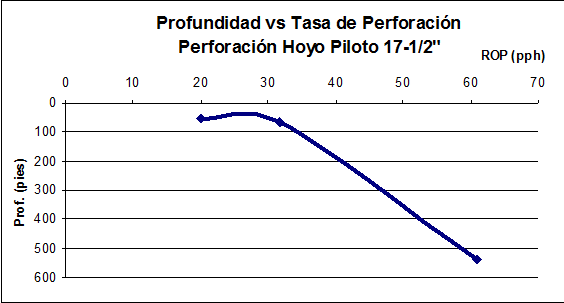

Author of the curve graph: @carlos84. Represents the Depth vs. Drilling Rate - Conductor Hole 17-1 / 2 ".

If we analyze the Perforated Depth versus Drilling Rate chart, we can see that as the depth of the ROP increases (feet drilled per hour that passes) it increases, the reasons are obvious, as we go deeper into the well, we realize that the sands are poorly consolidated and we find ourselves with softer lithological strata cut by the wick, reason that increases the ROP penetration rate as we deepen in the hole drilling of 17-1 / 2 ".

Perforation of the surface hole of 17-1 / 2 ".

Performed 17-1 / 2 "surface hole with directional string (back-up + MWD), using 17-1 / 2" tricone wick from 1009 'to 4207'; 17-1 / 2 "PDC wick, from 4207 'to 6551'. The perforation was performed with the following parameters: GPM: 750 - 900, RPM: 120-140, Weight on the wick (PSM): 5-10 Klbs. the KOP went to 1800 'and built an angle until reaching the maximum planned inclination of 22 ° with an azimuth of 278 °, at depth 3869' (MD), then maintained tangent to the planned depth 6022 '(MD). The fluid used was semi-dispersed water base with a range of densities between 9.5 lpg and 10.5 lpg.

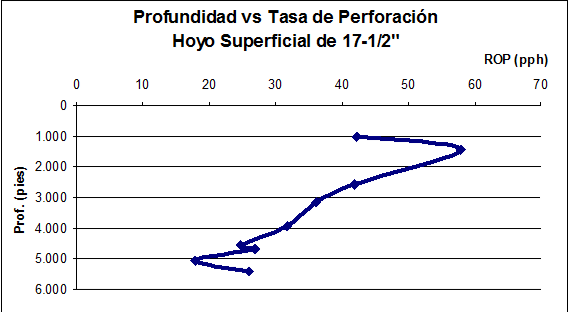

Author of the chart graph: @carlos84. Represents the surface hole drilling rate of 17-1 / 2 ".

Author of the curve graph: @carlos84. It represents the graph of the curve of the depth of feet drilled versus the ROP, it can be seen how at the depth of 1000 to 1500 feet there was an increase in the rate of drilling (ROP), from 1500 to 5000 feet approximately decreased from 58 feet per hour to 18 feet per hour, then begin to increase the ROP, a situation that makes us think that from 1500 feet up to 5000 feet a hard formation was crossed, which decreased the ROP.

Summing up a little the description of the construction of the Fra-21x well, it is necessary to assume this same procedure for the other phases of the well, where its perforability is analyzed in the same way as it was done in the other phases.

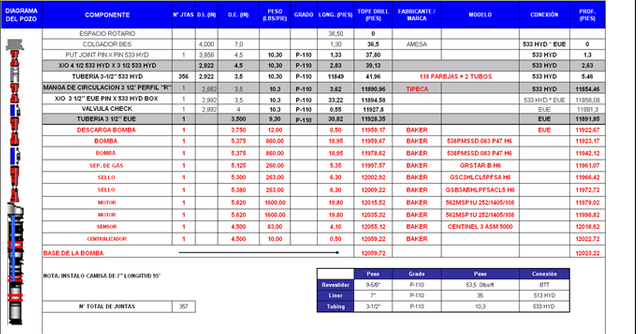

Completion of the FRA-21X well.

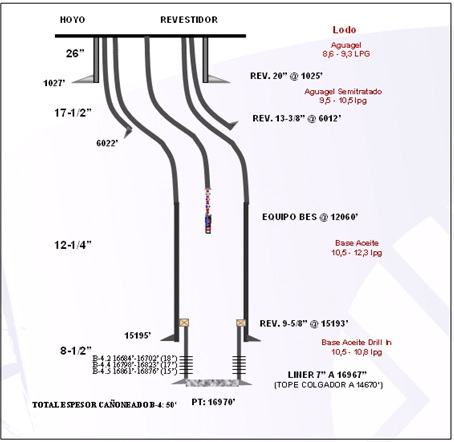

The well was completed BES type with 356 pipe joints of 3-1 / 2 "" 10.3 lbs / feet P-110 thread HYD 533, a circulation sleeve of 3-1 / 2 "profile" R "(ID: 2,562 ") HyD 533 thread and Electro submersible pumping equipment, with BES Completion at 12060 ', as shown in the figure:

Author of the completion detail of the well: @carlos84. It represents the exact diagram of all the tools that were lowered to complete the well by means of electro submersible pumping.

Final results in the construction of the well.

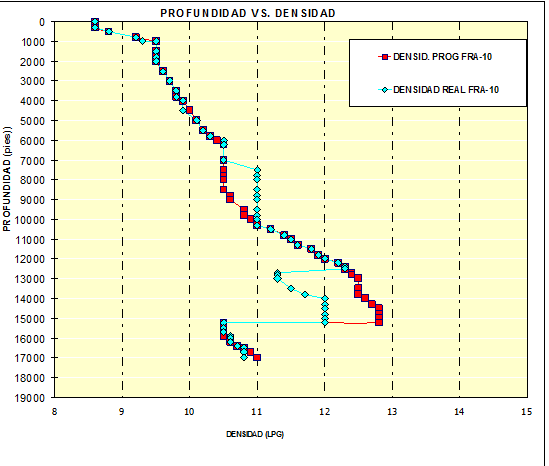

Depth curve versus drilling fluid density.

Author of the mud curve graphic: @carlos84. It represents the depth chart versus the density of the drilling fluid.

The analysis of this graph can be focused on the fact that the red curve represents the mud density curve according to the well program, while the light green curve represents the actual density of the well. In the whole section it is seen that the real density is equal to that of the program, only in the 7000 to 10000 ft section a distortion is noted where it was drilled with a density below that of the program, this was because at the time of continuing drilling this phase there were no chemical additives to continue drilling this phase with the programmed density, the hydrostatic pressure calculations of the drilling fluid were made and compared with reservoir pressure, and it was concluded that drilling could be continued with a lower density than the one programmed in that section. Then from 13000 to 15000 feet you see the other lag, where the real density is higher than the programmed one, at this point it was decided to increase the density of the drilling mud, since the records that were run at that depth gave site greater than the program.

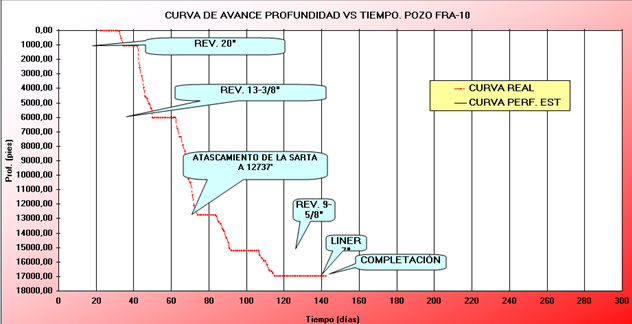

Pierce curve.

Author of the curve graph: @carlos84. It represents the depth versus time graph.

If we compare the estimated time according to the program with the real time in the construction of the well, we can conclude that the red curve that is the real time, all the time is above the estimated according to program, due to various problems that made having times unproductive such as bad weather, pipe clogging and other problems of an operational nature.

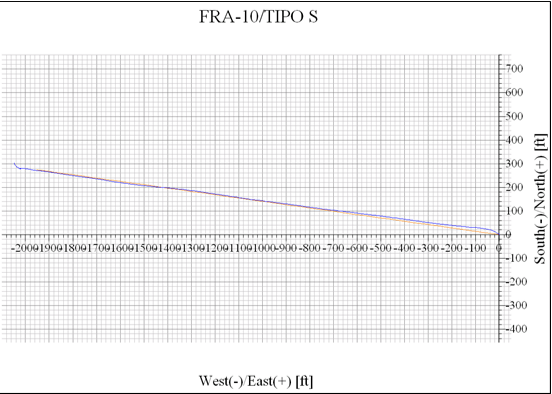

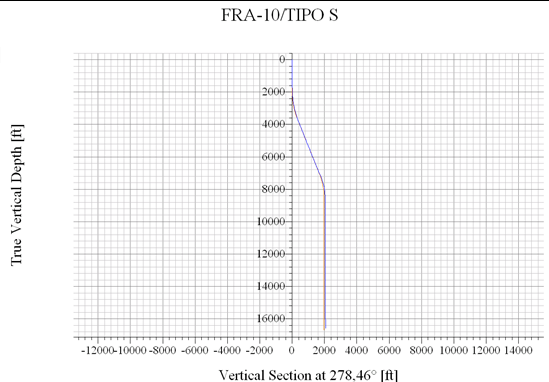

Trajectory of the well.

Horizontal projection of the FRA-21X well. Author: @carlos84

Vertical section of the FRA-21X well. Author: @carlos84

Mechanical diagram of the well.

1.Proposed

Author of the image: @carlos84

- Real

Author of the image: @carlos84

Conclusion and recommendations.

The operational planning of the FRA-21X well was of 153.81 days, according to the last revision and culminated with 141.83 days, +/- 12 days below the last revision, obtaining a positive return for the nation of 2655 , 5 MBs, only for the concept of the daily rate of the contracted drill. However, pipe clogging during the drilling of the original 12-1 / 4 "hole led to the generation of unproductive time, which increased the times and final costs of the well construction. For this reason, the BHA directional designs and the optimal drilling fluid selection are important, to obtain an excellent performance at the level of drilling rate and economy of the project.

It is important to have information from neighboring wells to make sound decisions regarding the increase in mud density, taking into account the lithology of the formation and results obtained in short trips.

Get more information regarding the pressures of the drill formation.

Keep the static drill string as short as possible.

Perform calibration trips on each hole before:

- You run electrical records.

- Carry out runs of coatings.

- When pit instability problems exist.

- Carry out special tests on the Base Oil fluid as many times as necessary

- Maintain a good distribution of granulometry or carbonate in the system.

Bibliography consulted

Technical report. Final construction report of the Fra-21X well. Author: Carlos Balzán. 2012. PDVSA. Building the Menito. Lagunillas Edo Zulia- Venezuela.

Drilling Manual. Procedures and operations in the well. Author: Datalog. David Hawker Karen Vogt Calgary, Alberta, Canada. July 2002

Book. Fundamentals of Drilling Engineering. 1st edition. PDVSA 1998. Ciudad Ojeda, Edo Zulia - Venezuela. International Center for Education and Development (CIED).

I think your Post @carlos84 is extraordinary, that's why I have dried you up to learn from your wonderful publications.