The science behind the scoby (Growing leather)

Growing leather

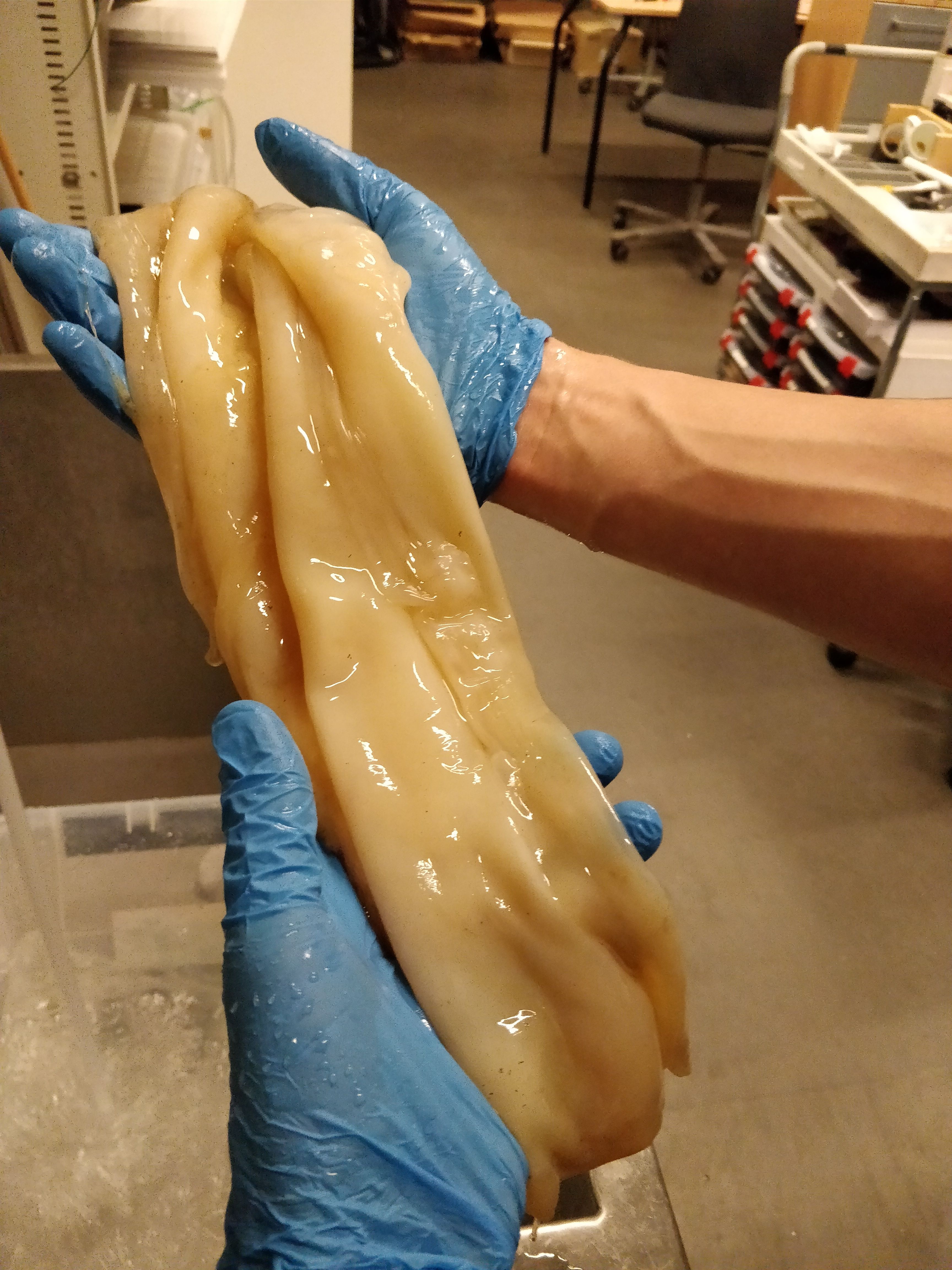

So as some of you know, i am writing my bachelor project about creating an eco friendly version of leather. The ultimate goal is to bring textile production into the home, by using the layer of cellulose, the “Scoby” created as a byproduct of kombucha (a chinese fermented tea). The reasoning for this has been explained in an earlier post, but it mostly comes down to the fact that the production of leather and textiles is often bad for both environment and the people working with it. We therefore aim to design an enclosure that makes it as easy as possible to grow a satisfying quantity of textiles in your own home. As the process is somewhat smelly, and the unprepared scoby can seem somewhat off putting, the main challenge lies in making the growth enclosure as presentable as possible. We want it to be integratable into the common household, which is what we will be aiming for.

So how does it work?

Anyhow, before starting the design phase of the enclosure, the group i am working in have gone through a range of experiments in order to find the recipe that resulted in the most efficient scoby growth. I will write about these experiments in the future, but in order to do so, i first need to explain what has led to these experiments. In this post, i will therefore, in somewhat brief terms, explain how the Scoby is created. In all honesty, i have been putting off writing this post for a long time, because the amount of scientific papers on the area are quite scarce. I did not want to start writing without proper knowledge on the area, and thus, i have been putting it off until now. BUT NO MORE!

Even though i have not been able to find all the info i would like to, i will share the knowledge that i have at this point, and use it as a stepping stone for my next couple of posts.

Not just one type of kombucha

So, as stated in my previous posts, kombucha is a chinese fermented sweet tea, containing a symbiotic culture of acetic acid producing bacteria and yeast (Nguyen et al. 2008, Shade 2011).

It is important to note that the strains of yeast and bacteria can vary widely based on where it is grown and the conditions it is grown under. The drink itself dates back thousands of years, and has spread across the globe. Many variations of kombucha therefore exists, and you therefore cannot simply explain kombucha shortly (ibid). However, as i am interested in the production of cellulose, i will be writing about the cellulose producing bacteria strains.

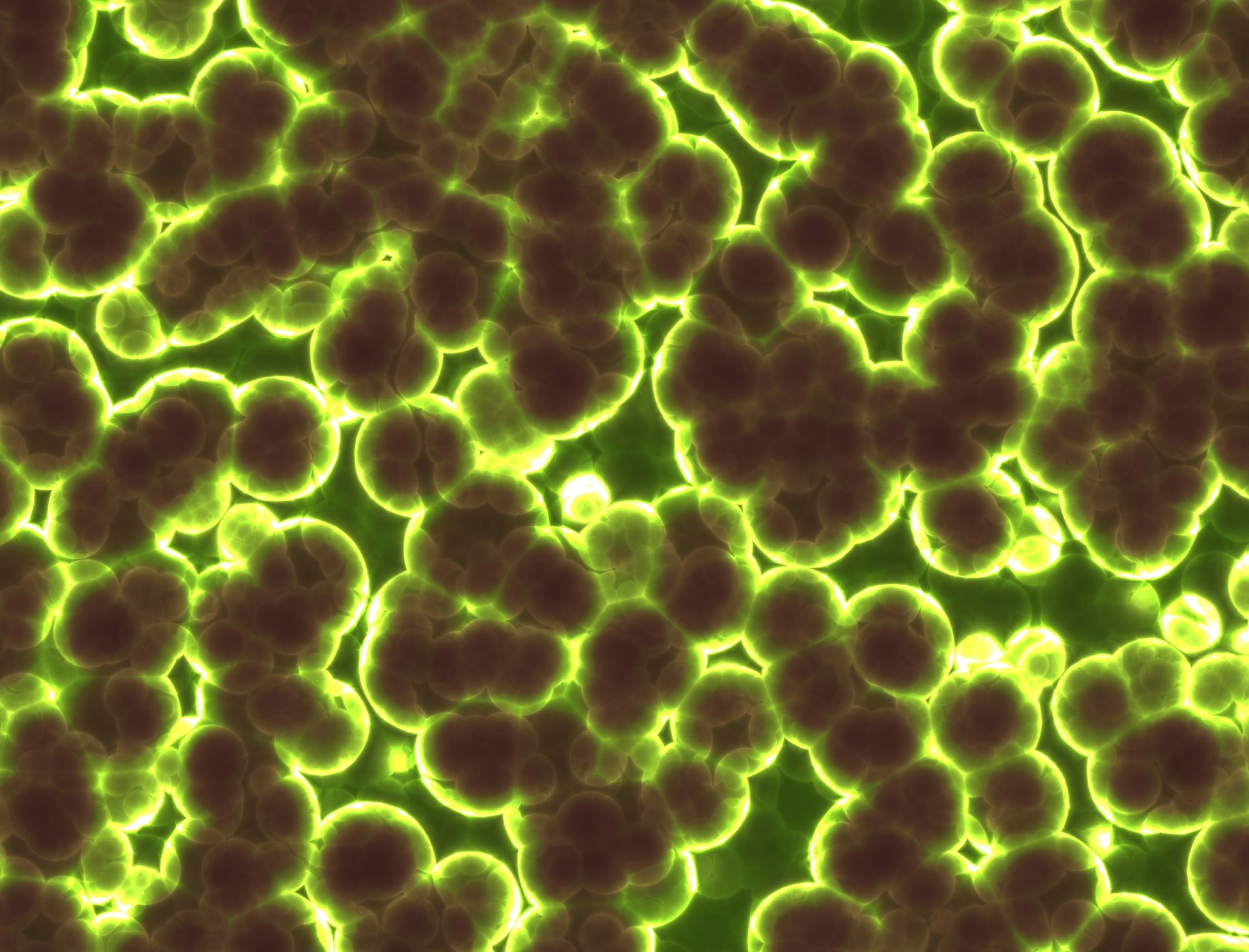

While the bacteria strains, as stated earlier, vary widely, the main ones are Acetobacter, Agrobacterium, Gluconacetobacter, Rhizobium, and Sarcina (Ibid.). Naturally, the distribution of the bacteria from brew to brew, and they do not all necessarily exists at once.

As said, the kombucha containss both bacteria and yeast. The yeast is fermenting the sugar (typically sucrose), to ethanol, while breaking it down to glucose and fructose. This allows for the bacteria to use the sugar as a carbon source for producing the bacterial cellulose (Shade 2011). The fructose is converted into acetic acid, and the glucose is converted into gluconic acid. This gives the liquid a strong smell/ taste of vinegar, which becomes more potent as times goes on. The longer the time, the lower the PH value (Ibid.). The bacterial cellulose is a byproduct of this process. When the mixture of tea, sugar, bacteria and yeast comes in contact with oxygen, it starts producing the cellulose. Thus, a jelly like layer starts forming on top of the liquid, spreading over the entire surface, thickening over time (Dutta et al. 2007). This can go on until the mixture runs low on nutrients, at which point the layer will stop growing in thickness. As the process is dependent on oxygen, having the largest possible surface area has shown to accelerate the conversion of sugar and tea to kombucha (culturesforhealth).

As we are working with a wide range of different strains of bacteria, it is hard to accurately pinpoint what affects the growth of cellulose. There does however seem to be a correlation between levels of caffeine, tannins, temperature, time, the type of tea and the complexity of sugar, and the growth of the scoby (Nguyen et al. 2008, happyherbalist). We will be growing scoby using different kombucha recipes factoring in all of these elements.

Possible uses

The production of bacterial cellulose is interesting for several reasons, and the reasoning goes way beyond my own goal of homegrown textiles. While plant based cellulose is extremely abundant in nature, the production of bacterial cellulose can result in a product that is both more pure, and has a higher mechanical strength (Goh et al. 2012). Interesting application areas includes, but are not limited to; acoustic transducer diaphragms, wound treatment, beauty products, plant fertilizer, parchement, food and electronics (Kim et al. 2015, Kombuchakamp, zsa et al.2014). We have already been contacted by soft robotics designers, material designers, and artists, asking about how they could use the scoby in their own work. For now, it seems very promising, and i am looking forward to getting further into the process.

Thanks a ton for reading, if you made it this far! Stay cozy

Cheers

Sources

Goh, W.N., Rosma, A., Kaur, B., Fazilah, A., Karim, A.A. and * Rajeev Bhat (2012) Microstructure and physical properties of microbial cellulose produced during fermentation of black tea broth (Kombucha). II

Ashley Shade (2011) The Kombucha Biofilm: a Model System for Microbial Ecology

Debasree Dutta and Ratan Gachhui (2007) Nitrogen-fixing and cellulose-producing Gluconacetobacter kombuchae sp. nov., isolated from Kombucha tea

Vu Tuan Nguyen Æ Bernadine Flanagan Æ Michael J. Gidley Æ Gary A. Dykes (2008) Characterization of Cellulose Production by a Gluconacetobacter xylinus Strain from Kombucha

S.S. Kim, S.Y. Lee, K.J. Park, S.M. Park, H.J. An, J.M. Hyun, Y.H. Choi (2015) Gluconacetobacter sp. gel_SEA623-2, bacterial cellulose producing bacterium isolated from citrus fruit juice

Faezah Esa Siti Masrinda Tasirin Norliza Abd Rahman (2014) Overview of Bacterial Cellulose Production and Application

Kombuchakamp https://www.kombuchakamp.com/kombucha-scoby-cultures-top-5-other-uses

culturesforhealth https://www.culturesforhealth.com/learn/kombucha/how-surface-area-affects-kombucha-brew-time/

happyherbalist https://www.happyherbalist.com/analysis-of-a-kombucha-ferment/

I've been following this project since your first post. I'm really excited by what you're trying to do here.

Thank you so much :) It's definitely a fun project!

Ooo the scoby is back! So cool that it has greater mechanical strength potential than plant-based textiles. All the possible applications for it are really intriguing and I can't wait to see what ends up happening with your project.

It does seem to have a lot of advantages. Also, it is very energy efficient to make, so it could solve a whole lot of issues :) I'm not totally sure where it will end up yet, but i know it's fun :D

I just can't wait for vegan leather to go mainstream!! This looks so exciting =) Love to see what you do here. Great job =)

Me neither ^^ It really is fun to experiment with. I'm gonna start making stuff from the leather soon, i'm sure that will prove to be quite cool

Really looking forward to see that :) Would be so happy to see more and more clothing in vegan leather :)

Congratulations @emilclaudell! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

To support your work, I also upvoted your post!

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP