Industrial process of a cheese rennet tank in Táchira-Venezuela. 🌃🚀

Greetings my dear Steeminas, my apologies for the absence of so much time I have not forgotten, only that always the ideas and topics that I want to show you I want them to be useful and support in the knowledge that many users want and this often takes me time. Today I bring something different, related to the explanation of a process that is very important for a product of mass consumption, such as cheese. Many times we see how this process is carried out, what we do not know is that at the industrial level there is an automation that allows the cheeses that are marketed according to each type to be the same when talking about a series of the same product.

There is a set of parameters that must be taken into account in a process, from the input of the raw material to the final product, well that is what will be described in this article below, whose case study will be the rennet tank. a cheese shop, specifically in the Táchira-Venezuela state:

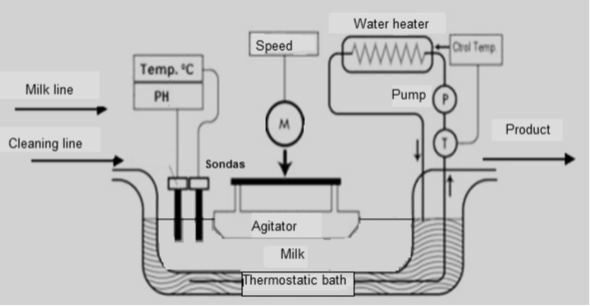

Tank or tub: It is the tank to pour the milk for the rennet process. The tank has four control variables: temperature, revolutions per minute (RPM), level and PH. These variables are captured by means of sensors: resistance RTD PT100, inductive speed sensor, level sensor and PH sensor. The conductive probes of temperature, PH and level are immersed in the tank and the inductive sensor is placed on the shaft of the agitator motor. The tank or tub has a three-phase motor, controlled by a speed variator, allowing to move in a specific way the stirrer of the tub. The water found in the thermostatted bath is driven through a recirculation pump to a water heater to maintain the desired temperature for the milk rennet. The cleaning line is activated when the product is completely drained.

The tank or tub contains:

• Water heater.

• Thermostat.

• Recirculation pump.

• Adjustable temperature control.

• Stirrer with adjustable speed.

• Temperature sensors, pH, level and inductive speed sensor.

• Level, temperature, PH and speed (RPM) indicators.

• Solenoid valves.

Source own

Tank safety components:

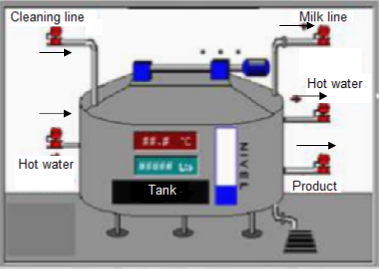

The following figure shows the HMI (Human Machine Interface) seen from the main screen of the SCADA system for the rennet process in the cheese plant.

Safety valves for reservoir: It is used to dislodge the liquid flow of the product, for a conduction escape relief by overpressure in pipes.

Maximum and minimum milk level control: The maximum level control device limits the filling operation to the maximum capacity of the tank. The minimum level control limits the emptying operation to the minimum capacity required by the agitator.

Beacon: Allows the operator to observe at a glance the level of the tank, being a safety component that is visibly faster in order for the operator to take corresponding actions of the process.

Source own

Elements of the process

Frequency inverter: Allows you to control the speed of the agitator motor.

Resistance sensor (RTD): Consists in the variation of the resistance in ohms of the conductor with the change in temperature. This sensor is used to sense the temperature of rennet in the tank.

Level sensor: Allows milk level control in the filling of the storage tank, which is done from the feed line called the milk line. To determine the limits of the level, a conductive probe is used for ON / OFF control. In this sense an approximate measure is obtained to control the frequency variator for the speed of the agitator according to the resulting product that is desired, this refers to the type of cheese that is delivering the production line.

Inductive sensor: Allows control of the speed of the motor containing the stirrer for each recipe, since it depends on the type of cheese a specific speed of the agitator in the tank for the rennet is established.

Recirculation pump: The pump recirculates the hot water, allowing water to be pushed into the tank inlet so that a certain amount of water is kept at a constant temperature for each recipe according to the rennet.

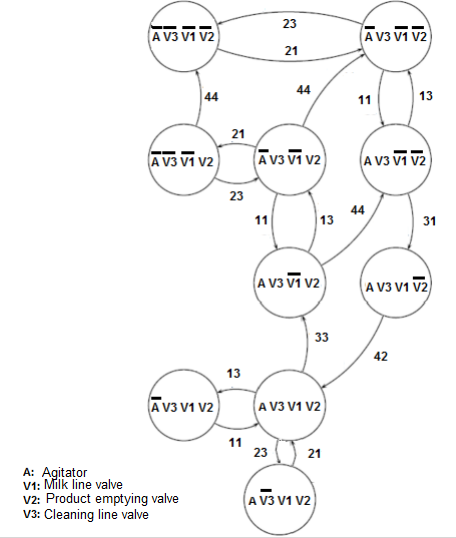

Event systems model

The events refer to all the possible combinations that may happen in the process, including faults in the valves or some logical or non-logical action that the process carries out during production. For this, a discrete event diagram is used and this is used by the control engineer who performs the automation of the cheese plant:

Source own

Each pair of numbers represents an identification to pass from one model to another, the bar that is shown above each letter, whose legend is shown in the figure means the OFF status of those variables that represent a device or element in the process, the variables that do not contain this bar means that they are in the ON state.

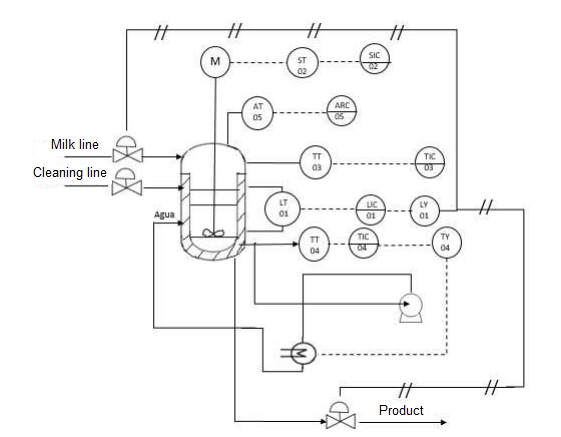

Instrument and pipe diagram

The diagram of instruments and pipes, is an electrical plane that represents the sensor elements identified as transmitters, which are responsible for transmitting to the controller all the data that is acquired from the process, then the converters that convert electrical signals to pneumatic signals, this for the case of activating or deactivating a valve.

Source own

Some references that apply Petri diagrams (discrete event systems) and ISA standards for instrumentation diagrams, are shown below:

Implementación de Redes de Petri para el Modelado y Simulación de un Proceso Industrial Mecatrónico

Aplicación de las redes de Petri a la simulación discreta de sistemas

Thanks my dear steemias invest your time in reading this article, if you have any concerns regarding the information in this article do not forget to leave your questions in the comments and I will gladly answer ... Do not forget if you liked this post:

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by gasuba from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.

Go here https://steemit.com/@a-a-a to get your post resteemed to over 72,000 followers.