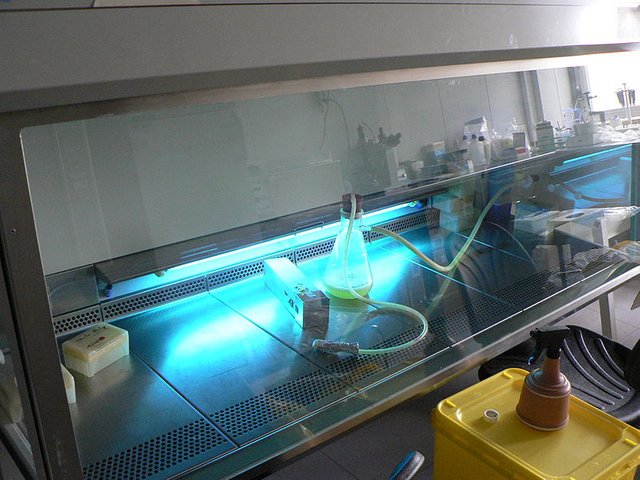

Ultraviolet Germicidal Irradiation (UV Disinfection)

Ultraviolet germicidal irradiation, source : Wikipedia

For some time now, I have been pondering on the dynamics of UV germicidal irradiation methodology of water and wastewater. I asked myself questions like;

How does it work? How can I disinfect water or wastewater with ultraviolet light?

When i was in school, i practiced more on chlorination, coagulation and flocculation. But on the course of studying and researching, I encountered the UV disinfection method. Which is quite an interesting method. Hence the reason why I put up this article.

From my research, I found out that UV germicidal irradiation is basically the application of UV light in the treatment of water.

But then, what is UV light?

UV light is simply an electromagnetic radiation that is higher in frequency than light. It is visible to the human eye. It has what is called electromagnetic spectrum between X-rays and visible light.

Why the application of UV light in disinfecting water?

The reason is because, microbial cells contain nucleic acids (DNA and RNA) which store genetic information. In order to live and reproduce, the cell must be able to replicate the biochemical information in these nucleic acids. Nucleic acids will absorb light of different wavelengths. Ultraviolet light, about 260mm ,will cause damages to the cells which will render them unable to replicate and cause their death.

Varying intensities of UV irradiation are required for the destruction of different microorganisms. The impact of the UV dose is quite different when particulates are involved. The particulates are impenetrable by UV irradiation and tend to shield bacteria.

Ultraviolet systems are designed to deliver the required dosage that will effectively destroy microorganisms at the minimum time.

In the disinfection of water or wastewater, there are two most commonly used UV disinfection reactor designs. They are quartz sleeve and polytetra-fluoroethylene (PTFE) tube reactors.

Quartz sleeve reactors employ water flowing over a submerged bank germicidal lamps. In PTFE reactor, fluid flows through what is called UV-transmitting Teflon tubes surrounded by germicidal lamps. Typically, fused quartz sleeves and virgin PTFE tubes have UV transmittance of 90 to 95% and 70-85 respectively.

Let's look at what the quartz is all about.....

Quartz Tube

One of the advantages of quartz material is it's virtual transparency to shortwave ultraviolet. Hence, it is used in the manufacture of germicidal lamps and many commercial ultraviolet systems. Conventionally, in quartz ultraviolet system water flows over a bank of quartz sleeves parallel or perpendicular to the lamp. Inside each quartz sleeve is a germicidal lamp. A separate 0-ring seal must be made at the end of each quartz sleeve. The outer shell is made of Stainless Steel, anodized aluminum or polyvinyl chloride. Quartz UV systems are designed for either pressurized or gravity flow.

What about PTFE tube? what is all about?

PTFE tube (FEP Teflon Tube)

Banks of germicidal lamps are placed in between the tubes so that each tube is exposed to ultraviolet light from all sides. Mounting the lamps on a frame enables their easy sliding for replacement. The outer casing is made of aluminum so that unabsorbed ultraviolet which strikes the enclosure walls is mostly reflected and absorbed by the water. The design is very efficient in terms of utilization of UV energy emitted by germicidal lamps, and in maintaining a turbulent plug flow pattern.

The use of Teflon material in UV systems is advantageous in the sense that it is an excellent transmitter of 253.7nm UV light, it is chemically inert and not attacked by substances present in water or wastewater and it is not affected by ultraviolet rays.

There are two configurations used in UV Teflon tube systems: the serpentine and the horizontal arrays configurations. In the serpentine configuration, flow enters the tube from the inlet and flow upward the distance of a germicidal lamp. Then the fluid flows through a 180 degree return bend and downwards for the same distance. The flow continues alternatively upward and downwards until it leaves through the outlet. This type of configuration is compact. it results in a high pressure drop of 2m which is too high for most gravity flow situations. It is used for drinking water disinfection at line pressure.

Design Considerations

The efficient design of UV systems requires careful consideration of certain important areas. .

Reactor Hydraulics

Hydraulics controls the flow velocity and the extent of mixing and hence the detention time in the system. High efficiency is achieved by minimizing axial mixing while maximizing transverse mixing. This is because transverse mixing allows for uniform dissipation of UV beam to all parts of the water. In order to achieve adequate radial mixing, the system is designed for turbulent flow. High dispersion results to short-circuiting. Low dispersion is enhanced by minimizing turbulence at the entrance and exit of the reactor and using high aspect ratios (length /width) in the dimensions of the reactor.

Transmission of UV light

The quantity of UV light utilized in the actual disinfection is dependent on the age of the lamp and the losses. The higher the age of the lamp the lower the quantity of light transmitted. Some of the UV is captured by quartz material, by air and so on and these contribute to losses.

Maintenance and Cleaning

Generally, UV systems are simple to operate and maintain. Maintenance involves the routine chemical cleaning of the system, periodic replacement of lamps, quartz etc , periodic replacement or repair of electrical components such as meters indicator lights and an annual cleaning, overhualing and repair of the system.

Cleaning of fouled tubes involves the mechanical wiper system, ultrasonic cleaning technique and chemical cleaning.

In the mechanical wiper system, a wiper periodically scrapes fouling deposits from the outer surface of the quartz sleeve. This technique requires hard-to-achieve very close tolerances for the wiper systems.

The ultrasonic method is based on the same principle that is used for cleaning laboratory glassware. The major problem is that ultrasound is destructive to quartz selves, germicidal lamps and 0-ring end seals. Besides the ultrasound does not penetrate into the interior portion of large tube bundles.

Both the mechanical wiper and ultrasound techniques must be supplemented with the chemical cleaning method.

In chemical cleaning method, soap, solutions of citric acid, sulphuric acid, sodium hydrochlorite and commercial acid detergents have all been used to clean quartz sleeves. It is also necessary to ventilate the entire lamp rack enclosure with filtered air as to prevent building up of dust on the dry surfaces.

Conclusion

We all know about other chemical methods to disinfect water and wastewater. Like the application of chlorine, coagulation and so on.

But more importantly, UV light provides effective inactivation of microorganisms through a physical process.

When protozoa, viruses and bacteria are exposed to the germicidal wavelengths of UV light, they are rendered inactive and incapable of reproduction.

UV germicidal irradiation is more active and preferable to other methods of treatment. Though it is quite expensive to put in place.

References For Further Reading

[1] Ultraviolet germicidal irradiation

[2] Introduction to UV Disinfection

[3] How Does UV Disinfection Work?

[4] Drinking Water Treatment with UV Irradiation

[5] Ultraviolet disinfection of drinking water

[6] UV Disinfection for Wastewater

[7] Wastewater UV Disinfection Control

Contribute STEM content using the #steemstem tag and #stemng tag (for Nigerians only) | Support steemstem authors | Join our curation trail | Visit our Discord community | Delegate SP to steemstem

Convenient Delegation Links:

50 SP | 100SP | 500SP | 1,000SP | 5,000SP | 10,000SP | 50,000SP

great content. keep it upp

Thanks for the feedback! @mitaenda

you are welcome

Good job explaining UV-disinfection of water! I worked in water quality research (an especially in karst and caves) for the latter half of my career. I've made a few posts about cave bacteria, but I am working on some posts pertaining to water quality, fecal bacterial contamination, and a method to determine what animal (or human) sources caused the fecal contamination. Let's stay connected!

Wow that's nice! Are you on discord?

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by masterwriter from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.