Cam and Camshaft; lets talk about what makes the valves move

Sometimes, the seemingly “little things” make a lot of difference and if in any way they are absent from a system, it would not be able to perform properly or even at all. This stands true for a lot of things as every part of a system is very important to ensure the efficiency.

This stands true for the automobile internal combustion engines too. They have a lot of parts that perform specific functions in accordance to the other parts to produce the required outputs. The bolts, washers, bearings, shafts, gears, levers rods and the likes are all equally important as the malfunctioning of one is going to affect the output of the whole system.

It has been a while I wrote about the automobile engine and I am having a feeling that my readers are starting to think I have forgotten my first love. Have I? Definitely not! Although I have been writing about some other stuff relating to engineering and sciences but not the automobile, my love for the automobile has not faded one bit.

Lets pop open the hood and peep inside the engine.

That's the inside of the cylinder head. Image source; Wikimedia commons under the Creative Commons Attribution-Share Alike 3.0 Unported license.

Today, I would be talking about one part of the automobile internal combustion engine that plays a vital role in the operation of the engine. Without this component(s) the engine cannot work properly in fact, it cannot function at all. Wondering what part of the engine could be so important? Well, no, it’s not the piston and neither is it the spark plug (diesel engines don’t have spark plugs). Read on to find out.

High school geometry taught me that a circle has no edges (does it?) and every point on its circumference is the same distance from the center point. As a result of this, if a circular object is pivoted at its center and rotated, every point on its circumference is going to pass through the same point. This however is not true for some other shapes such as the ellipse.

Let us perform an experiment

Take a piece of cardboard and cut out two circles of the same diameter. With one of the circles, cut out a heart or teardrop shape. Now take two pins, drive one into the middle of the circle and another at a point just touching the circumference of the circle. If you start to rotate the circle about its axis, as expected, every point on the circumference of circle (I would assume you cut out a perfect circle) would touch the pin. However, if the same thing is done for the heart shaped outline you cut, the shape would only touch the pin once in every revolution about its axis.

Are you wondering what I am trying to portray? Well, it is one part in the internal combustion engine that plays an important role in the functioning of the engine. Let’s do one quick recap of how the 4-stroke internal combustion engine works.

At the beginning of a stroke, the intake valve opens and fresh charge is sucked into the cylinder, the second and third strokes see the piston compressing the charge and it being ignited and producing power to push the piston downwards. However, at the last stroke, the exhaust valve opens to allow the combustion products to be ejected from the cylinder. Now the question is, what opens and closes the valves?

Hello there, CAM I help you?

If you have ever played the guitar before (like me), you would be familiar with the guitar pick and if not, you would have seen a guitarist with a flat piece of plastic shaped like a teardrop. I am not here to discuss the guitar (maybe some other time), the shape of the pick is what I want to point out. If the pick was used for the experiment we did earlier, we would have the same result.

According to oxford dictionary, A projection on a rotating part in machinery, designed to make sliding contact with another part while rotating and impart reciprocal or variable motion to it.

Simply put, a cam is a device that helps to convert one form of motion to another, usually rotational to linear. The motion of a cam is usually transferred (and transformed) to another part known as the follower. Cams usually come in various types depending on their application, shape and follower. Some of the common ones are the cylindrical cam found in the lathe machine, face cam such as in a slash window lock, heart shaped cam which as the name implies, is shaped like a heart, snail drop cam and linear cam.

Animation showing a simple cam mechanism. Image source; Wikimedia commons public domain

The most common cams however are found in the automobile internal combustion engine, the cam (teardrop shaped) rotates about an axis and at intervals the pointed part pushes the valve (or pushrod) downward and therefore opens the intake or exhaust openings in the engine cylinder.

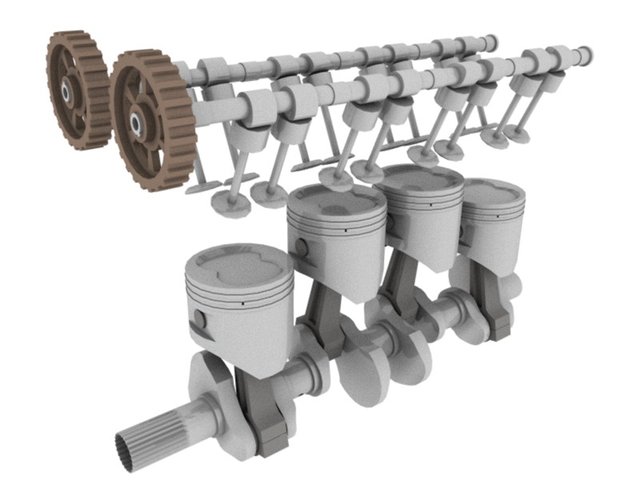

In the automobile engine, there are more than one cylinders (at least four) and there are going to be at least two valves (intake and exhaust) for each cylinder thus, for a four cylinder engine, there would be the need for eight cams to push each valve. As a result of this, the automobile engine does not possess individual cams but a series of cams on a shaft known as cam shaft.

Do you mean crankshaft?

I am sure you have heard something like that before – the cam shaft. You should also have heard about the crankshaft before. Confused? Don’t be. The two shafts sound similar but they are not and I would quickly demystify the difference between the two.

The crankshaft is the shaft that receives the linear motion of the piston and translates it to rotational motion i.e. engine output. It is usually attached to the piston via the connecting rod and as a result of the upward and downward motion of the piston and, would rotate. On the other hand, the camshaft is the shaft responsible for the opening and closing of the valves on the engine.

Now here comes the shocker; the cam shaft is connected to the crank shaft. Yes. The rotation of the cam shaft is dependent on the crankshaft. This allows for the opening and closing of the valves to happen at the right time and frequency. The cam shaft is usually connected to the crankshaft via the timing belt (and in rare cases a series of gears). From the name timing belt, you should know its work. In a later post, I would be discussing the concept of valve timing.

You know I mentioned that all the parts of the engine work in sync (well if I didn’t, I just did). The rotation of the crank shaft, camshaft (i.e. influencing the opening and closing of the valves) and the firing of the spark plug would need to be in perfect synchronization in order to achieve a perfectly working engine. If they don’t, the engine would not start and even if it does, it would stop working as soon as it starts.

A camshaft Image source wikimedia commons public domain

Now, back to the camshaft.

On different automobile engines, the camshaft configuration may differ depending on the engine type or design specification. As long as the camshafts can make the valves move, then they are good to go. These arrangements can be classified broadly into two and I would be discussing the three to wrap this article up.

THE OVERHEAD CAM

Just like the name implies, the cam is located on top of the engine (usually in the cylinder head) where they can push the valves directly. This type of cam configuration is usually in two types – the Single Overhead Cam (SOHC) and the Dual Overhead Cam (DOHC).

From the name, the Single Overhead Cam (SOHC) involves the use of just one camshaft in the cylinder head. Usually the number of camshaft is equal to the number of cylinder banks in the engine. What I mean is that, an in-line 4-cylinder engine would have a single camshaft while a V6-engine would have two camshafts (one for each bank). All the cam lobes for both the intake and exhaust valves are fitted in the camshaft thereby resulting in a restricted number of valves per cylinder.

On the flip side, the Dual Overhead Cam (DOHC) configuration involves two camshafts per cylinder bank i.e. a 4-cylinder engine would have two camshafts (just like in the image beside) while a V-engine would have four. Each camshaft operates one set of valves, i.e. one operates the intake valves while the other takes on the exhaust valve. The availability of separate shafts for the intake and exhaust valves means it is possible to have more valves per cylinder in the engine which helps to ensure smooth intake and disposing of gases affecting the efficiency of the engine positively.

Recall that the crankshaft is located at the other end of the engine (i.e. it is below the piston while the camshaft is above), both the single and double overhead cam configurations have the cam shafts connected to the crankshaft via a timing belt or chain.

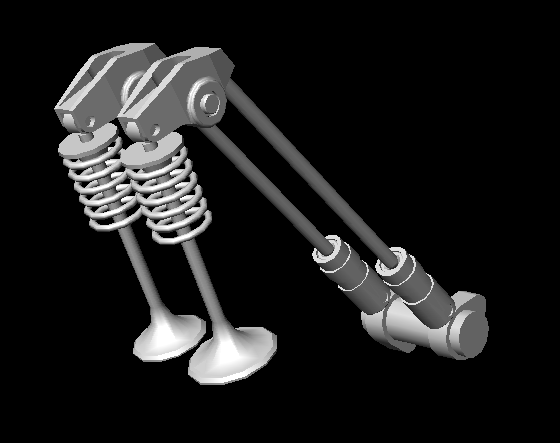

When the crankshaft rotates, the rotation is transferred to the camshaft via the timing belt and it turns. The nose of the cam (the protruding part) then presses against the valves which are fitted with springs for return.

THE PUSHROD CAM

Unlike the overhead cam configuration, the, pushrod config. has the camshaft inside the engine rather than on top. As a result of this, the configuration employs the use of pushrods to transfer the motion to the valves which are located on top of the engine. Just as the name implies, the pushrods are simply pushed by the cams at the intervals and these pushrods which run through the engine to the top pushes on the spring and valve mechanism at the top of the cylinder (just like in the image beside).

However, the pushrod configuration is not found in modern vehicles due to some disadvantages such as the fact that it involves more moving parts and thus more mass. These result in lower speeds attainable by the system, higher noise generated, more friction and/or wear and more difficulty when there is need for maintenance (you would have to tear down the engine to access the cam shaft).

Because the camshaft is closer to the crankshaft, the two can be connected via a gear or sometimes a small chain.

Whichever the camshaft configuration present in an engine, they all do the same job of transferring and translating rotating motion to reciprocating linear motion of the valves.

CONCLUSION

The camshafts in an engine are as important as any other part of the engine. If by any means the camshaft changes position (maybe as a result of a bad timing belt), the result would be a broken valve(s) as the piston motion would not be in sync with the valve motion and they would simply hit each other and cause a damage.

As a result of this, one of the maintenance practices car manufacturers recommend is a change of timing belt. If you think they are being paranoid, maybe you should think twice.

Cam shafts are not always visible when you look at the engine unless you open up the cylinder head (for overhead configuration) or you dismantle the engine (for pushrod system) but if you eventually get to see one, learn to say thank you to them for ensuring the flow of charge and exhaust in and out of the engine.

REFERENCES

Engineering Mechanisms; Cams

Camshaft fundamentals

Difference between cam and crank shafts

How camshafts work

Cam

Camshaft

Hi @rharphelle!

Your post was upvoted by utopian.io in cooperation with steemstem - supporting knowledge, innovation and technological advancement on the Steem Blockchain.

Contribute to Open Source with utopian.io

Learn how to contribute on our website and join the new open source economy.

Want to chat? Join the Utopian Community on Discord https://discord.gg/h52nFrV

Automobile mechanism are fascinating and interesting to read about. It's nice to read another of your auto-article.

Thanks for dropping by sir

Into the fascinating world of what goes below the hood of that motor vehicle. I notice some commercial bus drivers always complaining of either their cam or crankshaft. Any idea why that is so? Thank you for sharing your mechanical knowledge with us.

Most of the time those people do not really know which is which.

That being said, the issue common with the two is if the timing goes off and the engine simply stops running i.e the crank shaft and cam shaft are out of sync.

Or a broken, cracked out bent cam/crank shaft which doesn't happen everyday.

I think i will find it rather amusing if i see a (untrained, uneducated) commercial bus driver that knows what the cam/crank shaft is and does.

Except the bus driver is a mechanic, he most likely wouldn't know what a camshaft does, and even the mechanics do not pronounce it correctly, you'll hear something entirely different like caneshaft. That pronunciation confused me enough when I just began learning about engines and wanted to see one for myself.

Ok, that makes sense.

Mechanical and it's moving parts with different theories.... There is always something new to learn

Thanks because I got something fresh from this post sir

what makes the valve move🤔We learn every day.

Thanks for dropping by

Any Mechanical Engineer that has gone through the practical aspects of Auto Mechanics should know how important the cam shaft is.

Nice work pal.

Yeah, they are just so important. Thanks for dropping by

These days everything is being converted from mechanical to electrical.

It makes me wonder why camshafts haven't been replaced by electric actuators? Maybe they are too slow I guess?

Well, i have read about camless engines but they are not yet as common these days. they have not really been able to satisfy all the requirements i guess. But you never can tell what would happen in the nearest future, technology has a way of surprising us.

You can read about it here

Great. Thx for the info.

Reading your post, gives me more insight on automobiles. I do hear drivers talk about crank shaft but cam shafts, i have no idea. Thank you for the exposition

You're welcome. Thanks for reading through

Permit me to say camshafts are bae. They are probably my biggest favorites in the engine. I especially remember my Engineering drawing classes where we had to draw the movement of different types of cams and their followers.

The movement of Cam lobes is probably what amazes me about them the most, how they are designed along with the timing to ensure that they arrive at the point of need exactly when they are needed. Truth be told, if there is something wrong with the movement of these things, the engine is in serious trouble.

I can't end this without telling you about how these uneducated mechanics confused me in my early days of learning about engines. Anytime I asked them I'll like to see a camshaft, they'll tell me there is nothing like that in an engine. Until one of them asked me if i meant caneshaft, and I told him to show me that one. Alas!! he was referring to a camshaft 😂😂

This is a great exposé on my dear friends, let me say "Thank you" on their behalf.

I have a caneshaft in my workshop. Would you like to see?

First thing that crossed my mind was that I might not find this article fascinating.

And that's how I read till the end... I still don't get the way y'all make your articles so inviting. Good one

From the statement below;

Can we say that the crankshaft is even more important than this other guy (cam shaft)?

They both work together without one you can't have the other.

A little sauce and salt to taste!

Just like @adetola said, they are both very important. The crank shaft will not rotate if the engine is not running and the engine will not run if the valves are not opening, the valves cannot open if the camshaft does not do it's work and finally, the cam shaft will not rotate if the crankshaft doesn't.

I hope i didn't confuse you further.

P.S. Dont judge a book by its cover

is it cranskshaft or camshaft?