Beer Brewing: Top and Bottom Fermentation Technique

Brewing is the process through which beer is produced by starch steeping in water and the resulting sweet liquid is fermented with yeast. Starch sources usually used are cereal grains and barley which is the most popular. Beer production is done commercially in the brewery, homebrewer do it at home and indigenous people of Brazil has a variety of traditional methods such as communally used in brewing. Brewing has been in existence since 6th millennium BC and has been part of western economics since nineteenth century.

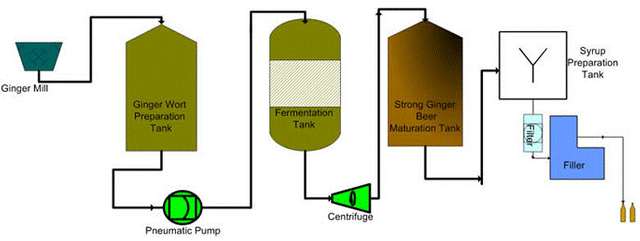

The proportion of each starch source that is present in a beer recipe is collectively known as grain bill.Steps Involve in brewing process are malting, mashing, boiling, fermentation, filtering, bottling and aging. There are two technologies of beer fermentation which are top fermentation technology and bottom fermentation technology.

Beer brewing procedures

Ingredients needed in the production of beer are Barley, hops, water and yeast. The main technique of beer brewing is about extraction of sugar from the grains which is usually barley and the action of yeast on the resulting solution turns it to alcohol and CO2 thereby creating beer.

Malting

This is the starting point of beer brewing and what is needed here is the grains which is usually barley. In malting the grains will be harvested, heat, dried out and cracked so that the grain kernel can be broken in order for the fermented sugar to be extracted and the product called grist is produced. Isolation of the enzyme needed for brewing takes place in malting. Then the next step comes in.

Mashing

This is the second procedure of brewing. In mashing, the grist are steeped in hot water which is not boiling for about one hour. This process is synonymous to tea making. Mashing of the grist activates the enzymes which were isolated in malting. This activation of the enzyme breaks down the grist and allows it to release sugar. After this, water from the mash which is now composed of the sugar from the grain is drained. The sweet sticky liquid is referred to as wort which is mainly an unmade beer as dough is unmade bread.

Boiling

In this part, for about an hour the wort produced at the mashing stage is boiled. During the boiling, hops and some other spices are added severally. Hops are small fruits from a vine plant. This hops helps in the balancing of sugar in the wort by providing bitterness. Also, it provides it with flavor. Hops are natural preservatives, which is their initial usefulness.

Fermentation

The is the process by which the glucose in the wort is been converted to ethyl alcohol and carbon dioxide gas by the help of added yeast. Thus, the beer now has both its carbonation and it alcoholic content. The fermentation process starts by transferring the cooled wort into a fermentation vessel which already has the yeast added to it.

The specific gravity of the mixture is measured at the initial addition of wort to the yeast. As the process continues, in order to know the amount of alcohol in the beer the specific gravity will have to be measured again, and this will help us to know when to terminate the fermentation process.

Except for a long narrow vent pipe, which permits the escape of carbon dioxide from the fermenter, the fermenter is sealed. Outside air is not allowed to enter the fermenter as a result of CO2 constant flow through the pipe. This prevents contamination threat by stray yeasts.

While fermentation is still going on, and the predetermined level of the specific gravity has been reached, the vent tube of the carbon dioxide is capped. As the vessel is sealed and fermentation continues, CO2 continuous production builds up pressure. From this, most of the carbonation of beer is gotten and in the later process the rest are added manually. The beer will remain under pressure from this point except during bottling for a short time.

The beer is cooled to a temperature of about 32F (0C) at the end of the fermentation process. This cooling helps yeast that remains to settle to the bottom of the fermenter. Also, at this lower temperature, other undesirable proteins come out of the solution.

The beer is now slowly pumped from the fermenter as most of the solids have settled to the bottom of the fermenter. After this, the beer is then filtered in order to remove any remaining solids. As the beer is been filtered it goes into another tank which is called bright beer tank before bottling or kegging .This is the end of fermentation process.

Bottling

At this point, the amount of carbon dioxide in the beer is adjusted through bubbling of extra CO2 into the beer by use of porous stone.

Difference between ale and lager beer

An average drinker of beer will always differentiate ale and lager beer based on their look, smell and taste. A brewer will always differentiate the two based on the type of yeast used in their production. The yeast for ale fermentation is entirely different from lager fermentation. Beer pedants will always describe the difference as “top-fermenting” (ale) and “bottom-fermenting”

Top fermentation of beer makes use of saccharomyces pastorianus as the catalyst. The temperature at which this procedure is carried out is 15-24 degree celcius and the complete process takes between 3-9 days. Bottom fermentation of beer uses saccharomyces uvarum as its catalyst. Bottom fermented beers are the majority of beers produced in the world. This fermentation process takes 6-12 days for its completion and at temperature of 6-12 degree Celcius.

Learn more about brewing from the video below.

References

- (https://en.wikipedia.org/wiki/Brewing)

- (https://science.howstuffworks.com/innovation/edible-innovations/beer4.htm)

- (https://www.nature.com/scitable/topicpage/yeast-fermentation-and-the-making-of-beer-14372813)

- (https://firstwefeast.com/drink/learn-how-to-brew-beer-with-these-fun-animated-gifs)

- (http://blog.beeriety.com/2009/07/06/how-beer-is-made/)

- (https://www.popsci.com/science/article/2013-01/beersci-what-difference-between-lager-and-ale)

Being A SteemStem Member