Yeah! Your car Engine is Self-sustaining, But How?

We have seen how an automobile engine is started before it becomes self-sustaining. If you missed that, do check out my post on automobile cranking system.

This is a sequel to the said article and we will be looking at the system that renders the engine self-sustaining having gotten it cranked in the first place – the Ignition system.

Given a fresh charge, that is, air-fuel mixture, every cylinder needs a spark after the compression stroke to ignite the compressed charge to initiate combustion. This spark is delivered by the Ignition system with the aid of a device known as the spark plug.

The spark raises the temperature of the mixture, thereby causing the required combustion. Achieving this spark is simple and requires multiplying the battery voltage of 12 volts to about 33, 000 volts or more by an ignition coil. This high voltage is passed on to the spark plug where it jumps an air-gap between two electrodes which then produces the spark that ignites the air-fuel mixture.

Having said this, It is worthy of note that this article focuses on modern Ignition systems which are strictly electronic ignition systems. The cars of the last decades used an Ignition system called Distributor ignition system. However, for quite some time now the automotive industry has been drifting more towards electrical systems.

.png)

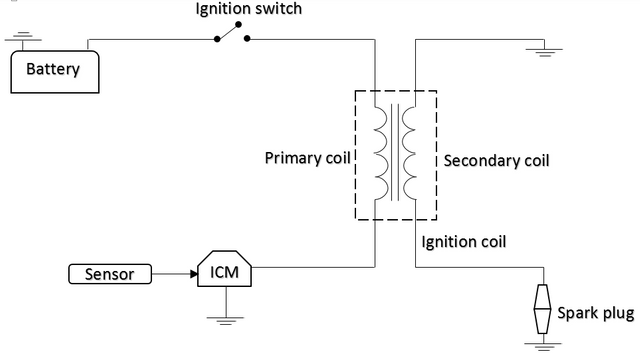

As shown in the schematic the electronic ignition system consists of an ignition switch, control module, sensors, ignition coils, and spark plugs.

When you turn the car key to the start position (or press the start button as in some new cars), the cranking operation is executed and as soon as that ends, the key returns to the on position thereby closing the primary circuit of the ignition coil causing current to flow in it.

If you have ever started a car engine, you will observe that upon releasing the key, it springs back from the initial position you twisted it - that is the key going to the on position, and as said, the primary circuit of the ignition coils is energized. In a layman’s term, power is supplied to the next device – the ignition coil.

Let’s teardown the ignition coil

As mentioned earlier, a spark is why the ignition system is in place. To achieve this spark, a very high voltage is required to jump the gap between two electrodes of the spark plug (we are coming to this soon). The production of this high voltage is the job of devices known as Ignition coils.

To better understand what an ignition coil is, simply think of transformers (not the movie series directed by Michael Bay), which is a device that either multiplies or divides voltage. The former is called step-up transformer and the latter is called step-down transformer. The ignition coil is obviously a step-up transformer.

Like every other electrical transformer, ignition coils consists of two sets of windings – the primary and secondary windings which are usually made of copper wire. In the real sense, transformers have no electrical connection between their windings, however, some ignition coils are constructed otherwise and thus are not real transformers. Nonetheless, their function still remains the same – substantially multiplying the 12 volts from the battery, so just take that as superfluous.

Generally, transformers are able to perform their job due to the difference in the number of turns in both the primary and secondary windings. If both windings were to be of the same number of turn, then there will be no voltage multiplication or division. The winding with the largest turns, handles the higher voltage and vice versa.

In the case of the ignition coil, the primary winding handles the 12 – volts of the battery and has less turns, typically 150 turns of heavy gauge copper wire. The secondary winding which handles the higher voltage has greater number of turns which could be as much as 20, 000 turns of relatively light gauge wire. At the core of the ignition coil is a ferromagnetic material, usually iron which strengthens the generated magnetic field. A cutaway of such coil is shown.

So, how does the Ignition coil work?

If you are familiar with the operation of a simple electrical transformer, then I guess this should be a piece of cake for you. The ignition coil works based on the principle of electromagnetic induction as every other transformer will do. Remember, a transformer has two sets of coils, the primary and secondary. When current is passes through the primary winding, it produces a magnetic field which cuts across the secondary winding. Consequently, voltage is induced in the secondary winding.

Now recall I mentioned that the ignition coil is a step-up transformer and thus the secondary winding has more turns (coils) than the primary winding. Thus, voltage is not only induced in the secondary winding, it is also greatly multiplied.

One point worthy of note is the fact that the principle of electromagnetic induction emphasizes that there be relative motion between the magnetic field produced by the primary winding and the secondary coils. Another way of saying this is that there must be a variation of the magnetic field of the primary winding for voltage to be induced in the secondary coils.

Achieving a varying magnetic field requires that the source voltage and hence current be varying as well. This is an inherent feature of alternating electricity. However, what you have in the car is direct current which does not vary.

In light of this, the current from the battery to the primary winding is cycled on and off at a preset interval. When the current is on a magnetic field is generated in the primary winding. At this time, no voltage is induced in the secondary winding since the magnetic field is constant. As soon as the source current is off, the required high voltage is induced at this instant in the secondary coils. The turning on and off of the source current is termed Ignition switching.

This switching is done by an electrical switch which is usually an integral of the Ignition control module (ICM), an electronic device that oversees the operation of the Ignition system. The Electronic control module (ECU) or Powertrain control module (PCM) is responsible for this function in other cases.

Knowing the right time to pulse on or off the source current is crucial as this determines when the required high voltage will be induced in the secondary winding. By now I’m sure you know why we need this high voltage – to create a spark for combustion.

The spark and hence the high voltage must be delivered at the instant which combustion is to occur in each cylinder. Consequently, toothed magnetic sensors are utilized to relay the position of the pistons to the control modules. Sensors used usually are the Crankshaft position sensor and the Camshaft position sensor. Wondering what their function is, well their names points that out.

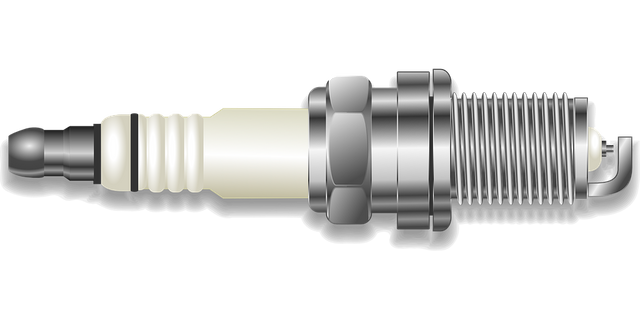

As they say, a tree cannot make a forest and as such, the spark plug is another major component in the ignition system. Spark plugs are devices used to produce the spark needed for the combustion of air-fuel mixture in the combustion chamber. It collects high voltage from the secondary winding of the ignition coil which causes a potential difference between a central electrode and a ground electrode, causing current to flow between them, thus creating the required spark. Confused? Let’s go further.

Let’s look at the spark plug construction from top to bottom (or left to right as shown)

First is a terminal, through which the spark plug connects directly or indirectly to the ignition coil. This terminal is like a threaded cap and is connected to a central electrode that is usually made of copper and sits at the core of the spark plug. Shielding the central electrode is an insulating material usually made of ceramic. As insulation, this insulating material provides a mechanical support for the spark plug. Next to the insulation, you find a hexagonal head, around which a wrench could fit to fasten the spark plug to the cylinder head.

Directly below the hexagonal head is a metal gasket or washer (a ring-like piece of material). Gaskets are used in any mechanical system to ensure proper sealing. The requirement of such piece is compressibility in order to fill any gap. The gasket is followed by a threaded shell that helps screw the spark plug in place in the cylinder head.

This threaded shell is internally insulated from the central electrode. If you pick any spark plug and look at the bottom, you will see a protruding metal surrounded by an insulation, that’s the central electrode I mentioned. Welded to the shell is a curved metal – the ground electrode which maintains a pre-set gap with the protruding central electrode.

So, how does the spark plug work?

The operation of the spark plug is simple. It begins with the flow of current from the ignition coil to the central electrode. As the current flows, a potential difference is generated between the central and ground electrodes. Initially, current is not allowed to flow between both electrodes due to the gap between them filled by air-fuel mixture which is an electrical insulator (a material that does not allow the flow of electricity).

As the voltage further increases, the nature of the gas mixture changes and as soon as the dielectric strength of this mixture is exceeded the gases become ionized and gain electrical conductivity, thereby allowing the flow of the high current between the electrodes. The flow of current heats up the gases and combustion takes place and this is what appears as spark.

Let’s wrap up summarily

Any system built is to achieve a usable entity. In this case, the ignition system is built all for a spark and by now I hope you know why we need the spark.

It all starts with the driver twisting the ignition key which technically results in closing of the ignition switch. By virtue of this, current is sent to the primary side of the ignition coil. Being a step-up transformer, the ignition coil greater multiply the voltage collected from the battery and then sends it to the spark plug. Thereafter, a potential difference is set off between the central and ground electrode of the spark plug and voila, a spark for air-fuel ignition and thus combustion is produced.

I hope I was able to present this article to you in a simple manner. Do ensure to ask questions or make contributions in the comments section. Thanks for being here.

Reference

- Halderman, J. D. Automotive Technology - Principles, Diagnosis and Services. (Fourth Edition)

- Nelson, M. and Parker, P. Advanced Level Physics. (Seventh Edition) Published by Longman International Education.

- How Spark plugs work

- The Dielectric Strength of Insulating Materials

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

I'm a proud member of @promo-mentors where you get mentored and guided on how to make quality posts on steemit amongst other benefits. Do join us on discord

. We anticipate your arrival.

the adage says "there is no smoke without fire" and it is vividly explained in the internal combustion engine, the "fire" coming from the ignition system.

nicely written sire... welcome back

Thanks man!

Whao....... At least I know sth about cars tonight.....thanks for the post.

Knowledge of Automobile principles is quite fascinating. I am glad you learnt something.

Hello! I find your post valuable for the wafrica community! Thanks for the great post! @wafrica is now following you! ALWAYs follow @wafrica and use the wafrica tag!

Hello @temitayo-pelumi

Nice article you got here..... When I start the car and notice that returns of the key I never knew there is a principle behind it and it is as deep as this taking about the ignition coil and the explanation with the electric transformer make the lesson more knowledgable and understanding.

I must confess, another knowledge is added to me today

Thanks man

Thanks for taking time to be here. I glad you find it worthy.

now i know more about spark plugs . The only thing i associated with spark pugs was that their malfunctioning result in my car jacking when i kick it or the generator refusing to start. Now i can teach my mechanic about the theoretical basis. Thanks for this.

Another lesson on automobile learnt this time again. A good one here, thanks for sharing with us.

Hi @temitayo-pelumi!

Your post was upvoted by utopian.io in cooperation with steemstem - supporting knowledge, innovation and technological advancement on the Steem Blockchain.

Contribute to Open Source with utopian.io

Learn how to contribute on our website and join the new open source economy.

Want to chat? Join the Utopian Community on Discord https://discord.gg/h52nFrV

I love the transformer analogy. It simplifies this for me. I have always been fascinated at the way ignition keys spring back to position. Nice digging

Kudos bro and welcome back. 😂