Your Car Engine is Self-sustaining, but How do we get it started?

Hello Steemians, it’s a pleasure having you here again.

Today, it’s gonna be another Auto-article. I want to take you into the core of getting the engine running. You might be well aware of how the engine continues to run, being self-sustaining but, have you ever wondered what got it started?

Perhaps you don’t even know how it keeps on running? Then let me give a summary.

Your engine runs on a thermodynamic cycle. It could be the Otto cycle as in petrol engines or Diesel cycle as in diesel engines. Regardless of what type of engine you have, they all share the same principle and here it is.

Air-fuel mixture is taken up or drawn in by the downward stroke of the piston into the cylinder (first stroke), and it becomes compressed by the piston through an upward movement (second stroke). The ignition of this compressed mixture occurs (this is done by a spark plug in the petrol engine and by virtue of the compression in a diesel engine) and as a result, there is a combustion which results in an explosion (expansion of the combustion products). An animation of a typical four-stroke engine is shown in the image on the left.

The expanding gases then push against the piston and forces it to go down (third stroke). By inertia (the reluctance of any object to change the state of its current motion), the piston moves up after the completion of the downward motion and pushes out the spent gases (fourth stroke) – tit for tat. This said inertia is not solely from the piston, but majorly from an element known as the flywheel.

Note: In actual sense flywheel is applies in manual transmission vehicles, it counter part is the flexplate in automatic transmissions. We will use the term flywheel all through this course.

It is worthy of note that the energy or power released during the combustion which then initiates the third stroke (a downward motion of the piston) is sufficient to get the subsequent strokes going – the fourth stroke, then another first stroke and second stroke, before the next combustion occurs.

But how do we achieve the first ever power stroke? In fact, you cannot have this power stroke without drawing in air-fuel mixture and not that alone, we have to have this mixture compressed before we can then introduce an ignition to produce the power stroke. So the question now is, how do we achieve the initial first and second strokes? Or perhaps, how do we get the engine running before it becomes self-sustaining?

Having said these, an external source of energy is needed to get the engine started or more technically, cranked. That is, we need to give the crankshaft an initial rotational motion, which is in turn transmits to the pistons, via their respective connecting rods. As soon as the engine becomes self-sustaining, the reverse becomes the case – the pistons supply the need rotation to the crankshaft.

Every internal combustion engine, no matter how big or small, requires a starting mechanism. The portable home electric generators popular in my country have internal combustion engines as their prime movers and getting them started usually requires pulling a retractable cord which supplies the crankshaft with the initial rotation needed.

In another case, you might have seen someone stand firm by a generator and then rotate severally a handle for some seconds and then you observe that he stops as soon as the engine begins to run. That’s probably a Lister diesel generator. But will you be surprised that cars were once cranked in this manner?

Yes, don’t be surprised

Before the 60’s, most cars were manually cranked by a crank handle. The driver will have to go to the front of the vehicle and make some turns before the engine could become self-sustaining. This method, however, was a tedious and dangerous one as there is the risk of kickback – a case where the engine’s direction of rotation (the conventional direction of crankshaft rotation) is reversed.

The crank handle always have a freewheel mechanism. This mechanism allows the engine to overrun the crank handle as soon as it becomes self-sustaining. However, this mechanism only works in the conventional direction of rotation of the crankshaft. Thus, in a case of a kickback, the crank handle will be forced to rotate and this is hazardous – a broken arm could result for the operator.

Today, things have turned out to be a lot easier and better.

Let’s find out

Automobile Cranking system

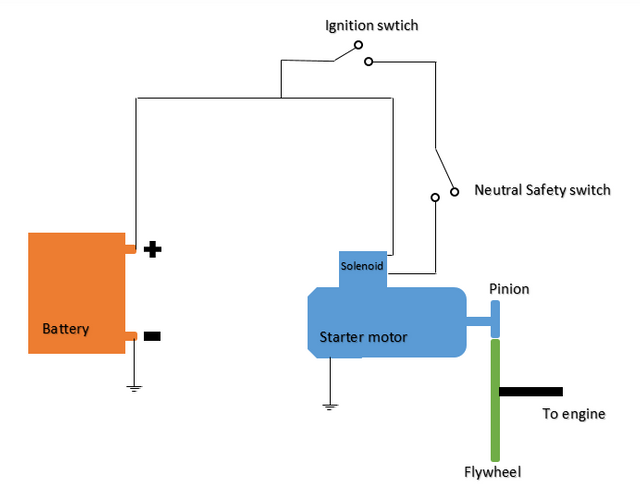

The word cranking is the technical term for getting the engine started before it becomes self-sustaining. Cranking is done by the cranking system which is an electromechanical system. That is, it involves the interaction of electrical and mechanical systems. The automobile cranking system is made up of some parts which come together to provide the starting function. They are:

- Ignition switch (usually key operated)

- Battery

- Starter motor

- Starter solenoid

- Neutral safety switch

The following discussion centers on the starter motor and the starter solenoid as they are the major components of the cranking system. However, every of the aforementioned part will be discussed in the discussion as their function surfaces – don’t worry, it’s gonna be like literally breaking the starting system into pieces.

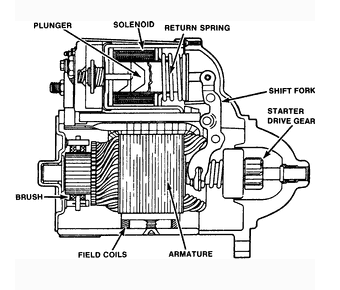

To avoid any confusion as we go further, be aware that the starter motor and the starter solenoid are both enclosed within the same housing. The image above shows the components contained within this housing. Let’s label them.

1 – Main housing, 2 – Overrunning clutch, 3 – Armature, 4 – Field coils, 5 – Brushes, 6 – Solenoid. The important components amongst the listed will be discussed as we go further.

The Starter motor

Recall that the sole purpose of the cranking system is to supply the engine via the crankshaft an initial rotational motion. But what gives us this rotation?

You might have guessed by the immediate heading that this is achieved by using a motor – the starter motor. This starter motor is like every other electric motor and thus works based on the principle of electromagnetic induction. Let’s see the construction of this motor.

The motor consists of two major parts – armature and field windings. The armature which sits at the core of the assembly consists of coils (several loops) of copper wire wound around a ferromagnetic core, usually iron. The field consists of four series of windings in conjunction with a pole faces all sorrounding the armature. Each pole face takes a magnetic polarity when the field windings are energized by electric current. The four poles faces provide four alternate magnetic poles of two north and south poles.

When the motor is energized, current is made to pass through both the armature and the field windings. A magnetic field by virtue of the current flowing through the series of loops of copper in the armature is generated – remember that a current carrying conductor will have a magnetic field around it. Another magnetic field is produced by the interaction of the four pole faces of the field windings. The interaction of these magnetic fields results in the rotation of the armature.

Now that we have what we need then, how do we get it to the engine?

Starter drive – Pinion and Ring Gears

What I did not mention earlier is that the armature assembly is mounted on a shaft. However, if you refer to the assembly image above you will get a better view of what I'm saying. This shaft thus receives rotational motion from the armature.

Connected to this shaft is a pinion gear (see the image to the left) enclosed within the starter motor that is in turn connected to a ring gear (see the image to the right) attached to the flywheel – they are collectively known as the starter drive. The flywheel on the other hand is connected to the crankshaft and thus delivers the rotational motion from the armature shaft to the crankshaft and viola, the engine gets the required help.

But what happens when the engine becomes self-sustaining?

The fact that the crankshaft is connected to the flywheel implies that it can turn the pinion gear of the starter motor. A typical pinion gear has 9 teeth and its corresponding ring gear has 166 teeth. By computing the ratio of the teeth of the ring gear to that of the pinion gear we have a gear ratio of 18: 1. This means the speed of the pinion gear is 18 times that of the ring gear. A typical engine starting speed is about 200 rpm and it can later accelerate to about 2000 rpm. Imagine what the speed of the pinion would be after such acceleration.

At this point, it is well established that the armature shaft will be turned (by the engine) as well, which will destroy the starter motor considering the potential speed, coupled with the fact that a motor becomes a generator when working in reverse. Consequently, there is need to disengage the pinion gear and the ring gear as soon as the engine is self-sustaining.

So, how do we do this?

Starter solenoid

We have provided the rotational motion needed for the cranking but we are yet to know how to disengage the engine from the starter motor when it begins to run on its own. Well, this is where the Starter solenoid comes into play.

The starter solenoid is an electromagnetic switch having made up of windings. These windings and thus the starter solenoid performs two functions. The first is to engage or disengage the starter pinion while the second function is to control the flow of current to the starter motor. The latter function makes the starter solenoid a Relay – an electromagnetic switch that allows a high current circuit to be controlled by a low one.

Fix it in your mind that these windings within the solenoid are simply electromagnets, that is, they are magnetized upon the application of electric current. These windings are connected to the battery and also to the armature of the starter motor.

When the key is turned on, initially, a strong magnetic force is produced within the windings of the solenoid. This pulls a plunger (refer to the image above to the left) to make contact with a contact disk. The plunger is mechanically linked to a hinged shift fork which pushes the pinion gear to engage the ring gear.

At the same time, a large amount of current is sent to the armature or simply the motor region of the assembly. The interaction of the magnetic fields of the armature and that of the field windings causes the rotation of the armature and in turn the armature shaft. Remember, the pinion gear is also mounted on this shaft and thus rotates with it, thereby transmitting the required rotation.

As soon as the Ignition key it turned away from the start position, the ignition switch opens, the motor seizes to operate and the plunger and hence the shift fork is retracted by the aid of a return spring, disengaging the pinion gear in the process.

It doesn’t end here

Like I have noted earlier, there’s a tendency that the pinion gear becomes overrun by the ring gear as soon as the engine takes control. The disengaging mechanism has been designed to disengage the pinion as soon as the engine is in control to prevent the problem of overrunning. However, there will always be a minute occurrence of overrunning which

is considered hazardous.

Consequently, the starter motor is equipped with an overrunning clutch which allows it to rotate the engine, but as soon as the engine’s speed becomes greater than that of the starter motor, this device runs freely preventing the motor from being driven by the engine.

Let’s draw the curtain by putting all the pieces together

.png)

If you have been waiting for the point where I will discuss how the system actually operates, that is, how the above discussed parts relate with one another to provide the cranking function, then we are here.

The illustration above puts all- the pieces into a whole.

Before we can crank the engine, one major condition must be met. This condition is that the Neutral safety switch must be closed.

But how do we close it?

To close this said switch, the transmission must be set to Neutral (in a manual transmission car) or Park in an automatic transmission car. The fact here is that cars are designed such that when this is done, the neutral safety switch will close other wise the starter circuit will remain open.

The cranking of the engine begins by the turning of the ignition key to the start position by the driver in order to close the ignition switch. This allows current to flow from the battery into the solenoid. Once the solenoid is energized and thus magnetized, it pulls a plunger connected to a shift fork. This shift fork in turn pushes the pinion gear into engagement with the ring gear.

Note: Some cars use a button operated ignition switch, instead of a key operated one. All you have to do in this case is to push a start button in the car.

At the same time, at the end of the motion of the plunger, it makes contact with a contact disk thereby closing the circuit of the starter motor. This allows current to flow through the starter motor and it then turns the pinion gear which in turn rotate the ring gear on the flywheel of the engine. Consequently, the required rotational motion is derived.

Thanks for reading through. I hope to have you here next time. Till then, keep steeming!!!

References

- Halderman, J. D. Automotive Technology - Principles, Diagnosis and Services. (Fourth Edition)

- How the starting system works

- Starter solenoid

- Engine Kickback

- Starter

People still do it, Dominic Teretto does it in those fast and furious movies.

The images really made your post pop!! You did a nice work with the article, it was a step by step procedure and I like that.

Dom probably had a vintage car... I doubt anyone will wanna go through such stress today.

Thanks for being here man.

More understanding of getting engine started. You've definitely added to my knowledge on this. Nicely written, thanks for sharing

My pleasure.

Since I was a little kid I was always astounded by engines, but I never really took the time to understand them fully! Thanks for breaking down some of the barriers that made them such mystery boxes in my mind :)

It's my pleasure to have you learn from my blog.

I fine it hard to agree with that.. If you say they have same goal I agree but same principles Is a no no for me because all engines are not piston engines

This is amazing... The starting process of a car

I have a question, if you really driving a car that starts with the push button and u mistaken push the button probably trying to traficate or something, what would happen... Never driven one of those

Let me state this clearly for you.

In this context we speak of Automobiles, and thus piston reciprocating internal combustion engines. Close your mind to any other type engine you know.

You could have stated you were talking about piston reciprocating internal combustion engines but you said

regardless of he type of engine you havemeaning any kindWell I know where you are coming from those.... Peace ✌️

Besides, did you consider the statement before that which you queried?

Please consider the statement carefully once more.

Thanks for dropping by.

I don't get you man

Where?

Please this is an avenue to learn not an argument

Thanks for replying tho

This is not an argument, I have only told you to consider that paragraph as a whole.

The principle of operation in automobiles could be complicated but you did well to break it down sir... Good job.

Old engines just like addempsea said are cranked before they start.

Yeah... The construction of the Automobile is a complex one. So I try my best to make it readable and I hope many can say the same as you. Thanks for dropping by man!

Its cool... I like the way you do that.. You are welcome bro!

if you want me to resteem your post to over 72,500 followers go here https://steemit.com/@a-a-a

Hi @temitayo-pelumi!

Your post was upvoted by utopian.io in cooperation with steemstem - supporting knowledge, innovation and technological advancement on the Steem Blockchain.

Contribute to Open Source with utopian.io

Learn how to contribute on our website and join the new open source economy.

Want to chat? Join the Utopian Community on Discord https://discord.gg/h52nFrV

At the push of a button or the twist of a key, the engine starts but a lot of people do not sit to consider how that came to be possible.

Precise, concise and dope!

Thanks for the kind words man!

most times when i read your post especially on automobiles I always think of basing my area of specialization even as a mechanical engineering graduate on automobiles because things that wasn't clear then in school are beginning to reveal itself. But production engineering all the way though(lol).more of this bro

i will be glad to learn

Automotive engineering is quite an interesting field and things are not complicated as it may seem. I'm glad you have been gaining through my writing. More is to come, so I will expect to have you here more as well.

Thanks for being here.

Anytime bro

You know engineering is another weird area of life. Lols. Nice to finally get a hand on how this thing works.

Good job bro.

Thanks man!