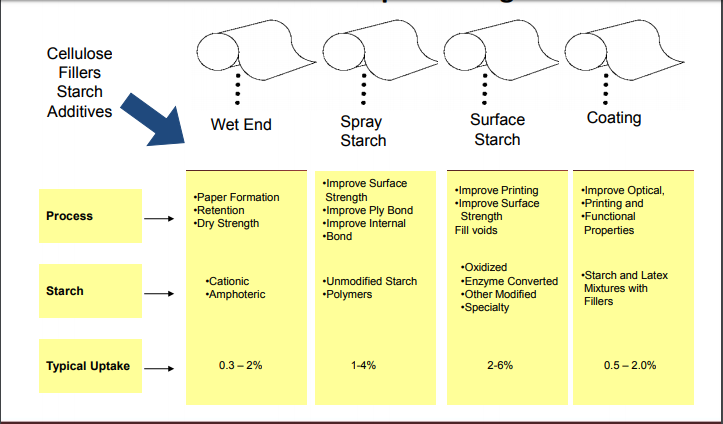

Surface Sizing using cationic starch vs oxidized starch/in mill modified starch by enzym

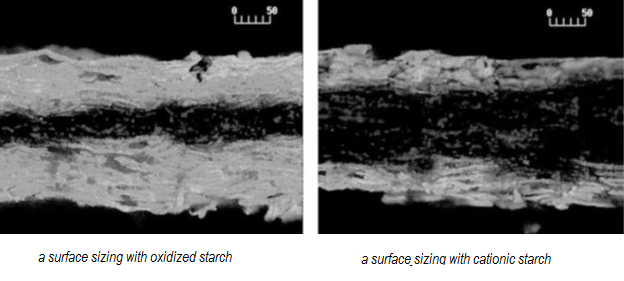

Oxidized starch or in mill modified starch by enzym commonly used for surface sizing tend to penetrate deeply into paper structure, and can caused reduced the opacity. and also an oxidized starch can act as anionic trash in the broke of recycling process.

We can solve the problems associated with conventional size press starches using a cationic starches.

A research results showed that cationic starches out performed oxidized starches in opacity, brightness, print gloss, and ink density due to their better holdout property. Effectiveness in surface holdout of cationic starches was verified using a confocal laser scanning microscope (CLSM). Adsorption ratio of the cationic starch onto fiber was substantially larger than that of oxidized starch, and this decreased COD load and increased fines retention and strength. We observed improvements in stiffness, opacity, brightness, printing quality, and picking resistance when ammonium persulfate starch was substituted with cationic starch in the film transfer size press. Furthermore, diverse beneficial effects of improving white water quality, including the reduction of COD and cationic demand, were obtained. Surface sizing with

cationic starch also gave better picking resistance and ink receptivity for coated paper than ammonium persulfate

starch.

Picture copy from http://www.tongaathulettstarch.co.za

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://www.researchgate.net/publication/280887077_Surface_sizing_with_cationic_starch_Its_effect_on_paper_quality_and_papermaking_process

Hii Robot...this posting are a basic theory and also mixed with results from several research, not only those link. We took from http://www.tongaathulettstarch.co.za.