3D Printing Technology: Making It Faster and Cheaper

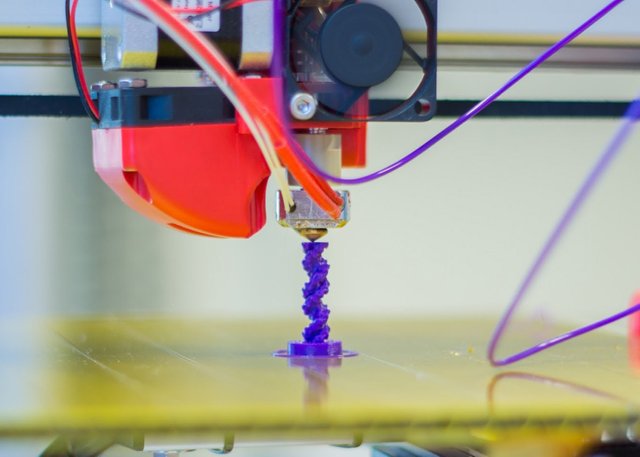

3D printing technology is incredibly versatile and this technology has made its way into dozens of different industries around the world. You can find 3D printers being used to print body parts, cars, houses, spoons, car parts, food items, and more. And one area that shows great promise for this technology is the business of manufacturing metal parts.

Faster & Cheaper

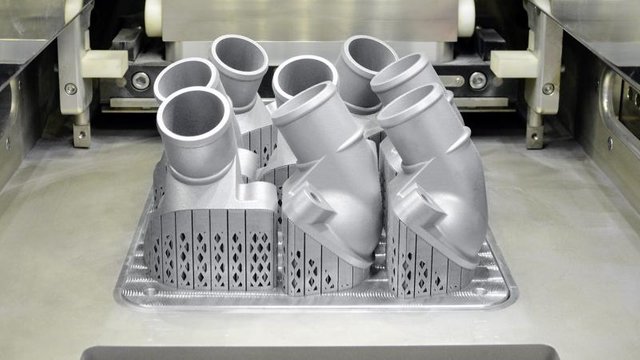

New 3D printers that are able to print metal parts, are allegedly able to work roughly 100 times faster than the current competitors on the market that are still using laser technology. Not only is the 3D printing method faster, it's also said to be around 10 times cheaper than the laser printing option as well.

To be more specific, a company known as Desktop Metal has recently developed a new 3D printer that is able to produce at this level of efficiency. Their creation is said to be one of the most efficient that is out there on the market today and it is capable of using a variety of metal options in order to create the product. Their design has also helped to drop the cost of materials by roughly 20 times that of conventional methods.

3D printing technology is being used in many creative ways and it has been said that this technology might soon become the most prevalent method of manufacturing worldwide.

Just recently, it was reported that Mercedes-Benz trucks had been working with 3D printing technology in order to create spare parts for the vehicles. For some out-of-production vehicles, those 3D printed parts have been classified for installation; thermostat covers for the engine.

The recently printed parts are said to offer a greater density and material purity compared to other parts that are conventionally produced. Now that the company has seen success with this printing method, it might not take very long for the process to gain traction and be used more frequently within the industry.

The 3D printing method increases speed and flexibility compared to alternative production methods.

3D printing technology is quite remarkable in that the potential seems limitless in what you are able to create. It appears that if you can imagine it then chances are that you might be able to create it with the 3D printer. From printing body parts and braces to automobiles and houses, this technology can serve people around the world in many different ways.

Mercedes-Benz isn't the only business getting familiarized with this technology either. General Electric is going to be using 3D printing to produce engine nozzles, Honda was able to create an electric car that was constructed mostly out of 3D-printed panels, Boeing has also looked into using 3D-printed parts too, and there are many others.

Current estimates suggest that roughly 67 percent of manufacturers have already started using 3D printing technology.

It is believed that by 2020 that 3D printing technology will greatly transform the manufacturing landscape. The global 3D printing market is expected to reach $21 billion by that time.

Pics:

dezeen.com via allthat3d

Gifsoup

Mercedes-Benz Trucks via fleetowner.com/site-files/fleetowner.com/files/uploads/2017/08/02/080217-Mercedes-BenzMetal3DprintedParts-Cluseup.jpg

Cerasis

Sources:

https://3dprintingindustry.com/news/fresh-off-3d-printer-metal-parts-mercedes-benz-trucks-119701/

http://inhabitat.com/new-metal-3d-printer-is-100x-faster-10x-cheaper-than-existing-laser-technologies/

https://www.allthat3d.com/best-3d-printer/

https://www.forbes.com/sites/louiscolumbus/2015/03/31/2015-roundup-of-3d-printing-market-forecasts-and-estimates/#602e4a271b30

http://www.businessinsider.com/honda-3d-printed-electric-car-drives-2016-10

https://techcrunch.com/2017/05/10/a-new-3d-printing-technology-uses-electricity-to-create-stronger-objects-for-manufacturing/

https://www.mentorworks.ca/blog/market-trends/3d-printing-technology-will-transform-manufacturing/

http://www.3ders.org/articles/20170802-mercedes-benz-produces-its-first-ever-fully-3d-printed-metal-replacement-part.html

Related Posts:

Undergraduate Student Uses 3D Printer To Make His Own Braces

3D Printing An Object Using Just Your Mind

https://steemit.com/technology/@doitvoluntarily/3d-printing-an-object-using-just-your-mind

The Creative Potential Of 3D Printing

https://steemit.com/health/@doitvoluntarily/the-creative-potential-of-3d-printing

The 3D Printing Company That Prints Buildings

https://steemit.com/technology/@doitvoluntarily/the-3d-printing-company-that-prints-buildings

I bought a 3d printer, next will be learning fusion 360

Bro.

Please print me some extra Liberty.

Heavy on the Liberty part. Send to #Canadastan immediately.

Great post @doitvoluntarily! You are absolutely right, printing metal objects is the next step in 3D printing! Plastic parts is very nice but very often you will need metal for strength and endurance!

Printed metal parts are not that dense. Maybe further down the line they could match the strength of a forged metal.

If you factor in some overdimension and sinter the parts after printing you could achieve higher densities.

One step closer every year...

Tasty surprise after the jump:

It's a replicator! Maybe one day. Are holodecks next?

Great article. I love the versatility in 3D printing. It's funny but true- you even have 'body parts' and 'spoons' as members of the same list of things that can be printed. Anything goes!

Upvoted and RESTEEMED!

I bought a 3D printer machine couple months ago for a project that I'm working in and well it sure takes patience , lots of persistence, but it can either come out to be a master piece or a total disaster

obvious 3D is the way to go. And I just upgraded from ink jet to Laser printer. I need to get with the system. LOL Thanks for sharing. -Troy

Great article! We need more tools like 3D printing to decentralize production and empower people to make their own stuff and be more self-sufficient. In Toronto some public libraries have 3D printers that anybody can use and they're also offering free 3D modelling courses. Isn't that awesome?