Industrial Automation Project

INDUSTRIAL AUTOMATION OF FLOUR DISPATCH PROCESS

Source

Source

Process description

The dispatch stage in the flour production plant is a system that is responsible for dosing the flour contained in the storage silos, to the bulk unloading area. The system has 4 storage silos. Each silo is associated with a series of equipment that transports the flour to the pipe system, which, with the air supplied by the two blowers, moves it towards the bulk unloading area.

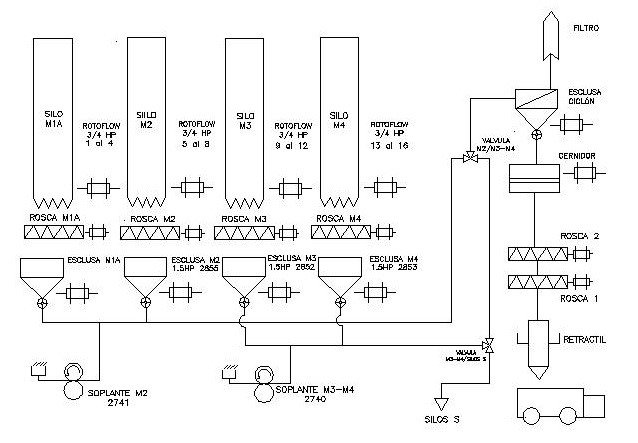

Process diagram

The following diagram shows the process of dispatching flour, the 4 silos with their respective associated equipment, the blowers and the bulk discharge stage.

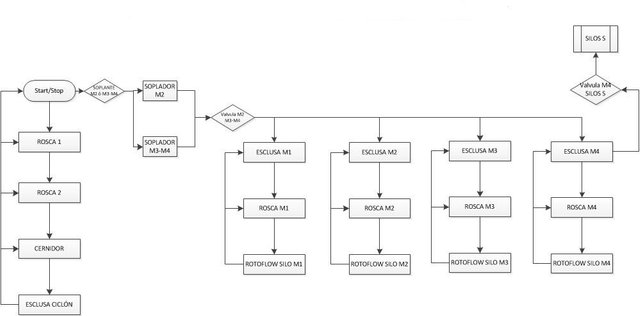

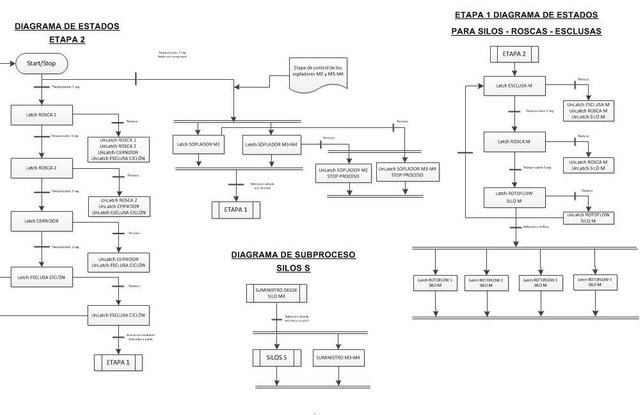

Flow chart and States

The following diagram served as a general guide to perform the programming logic in RSlogix5000. Taking into account the start and stop in sequence of the engines.

OPERATING PHILOSOPHY

The operating philosophy is based on an activation of thirty (30) engines which will be activated by the SCADA system depending on the silo with which the operator must work. They will have the purpose of transporting and dispatching bulk flour to the trucks. The application presents two (02) modes of operation:

Automatic mode:

The automatic mode is initiated through the SCADA, for which the following items must be verified:

• The remote selector of each of the motors must be in the Automatic position.

• The motor protection switch for each of the motors must be activated.

Once the previous items have been verified, the operator must make the selection of the work silo through the interface. The operator can choose the dosage of the product from any of the silos. Once the working silo has been selected, the operator can give the start command of the process.

Once the start command has been activated, the engines and equipment of the process will be activated sequentially. In parallel to the sequential activation, energy will be supplied to the blower associated with the selected silo.

After the successful start-up of this stage of the process and while there are no alarms or pressure losses in the supply pipeline, the operator in the field will be enabled to activate the dispatch process, with which he will be able to execute the start command from the keypad remote or through the operation panel also located in the field. After the start command the process will be activated sequentially.

Once the dispatch process has been successfully activated, the operator can dose the product to the transport trucks using the retractable, the motor associated with this will act independently of the sequence of the start of the process in general, which has an upward movement and When descending, these movements can be controlled by the operator using the remote keypad or through the operation panel located in the field.

Manual mode:

The manual mode of each motor is made through the control cabinet and force.

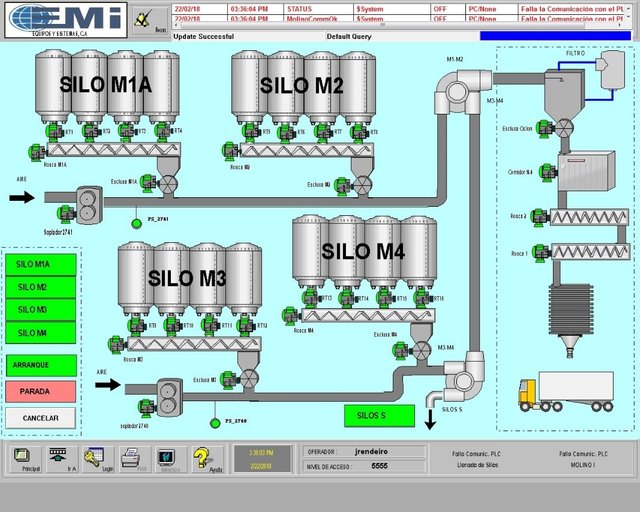

Screen Design

In order to solve the problems existing in the original control system of the dispatch process, an HMI interface was designed in Wonderware Intouch 2014, to perform tasks of control, supervision and monitoring, motor control, silo selection and dispatch. A general screen of the process was created which was integrated to the general application of the plant, where the user will be able to select the silo with which it is desired to dose flour and dispatch it to the trucks, and will be able to start the process. The screen is organized as follows:

• Selection of silo of work or dosage to silos S.

• Start, stop and cancel silo selection.

• Engine selection.

Also with the creation of the Tagsname of these new engines, the alarms and slogans of states for the process were assigned. At the same time they were integrated into the PopUp screen of engines. Having also then incidence in the screens of:

• Alarms.

• State.

• Engines.

The Wonderware Intouch 2017 software was used to design the screen.

Flour Dispatch Screen

The dispatch screen of the process was designed in order to facilitate the tasks of supervision and control of the process, it will show in real time the status of the engines. It has flour selection buttons from the silos M1A, M2, M3, M4 and sent from Silo M4 to Silos S. Start and stop the system and cancel the selection of silos.

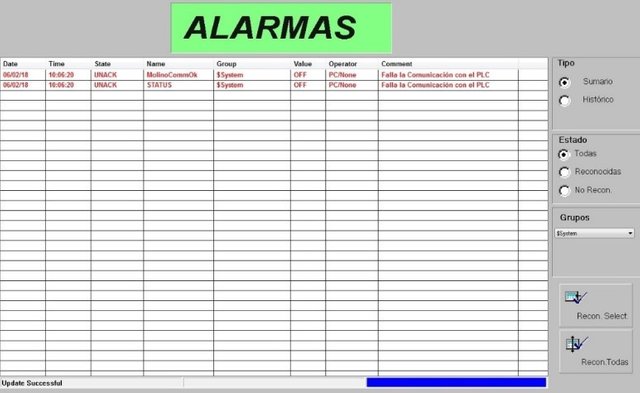

SYSTEM ALARMS

The application has an alarm system, which is composed of warnings that appear once the failure occurs. The alarms will be activated by each motor, whether a motor has not operated or if the motor protection switch does not allow its activation, as well as alarms for emergency stop and alarm of the capacitive sensor of high level in the cyclone lock.

The alarms that have occurred and registered can be observed through the HMI. On the other hand if for some event the pressure switches measure that the air pressure in the system increases, the blowers will continue to work, but an alarm will be issued and the supply of flour will be stopped. This does not saturate the system and the flour flows.

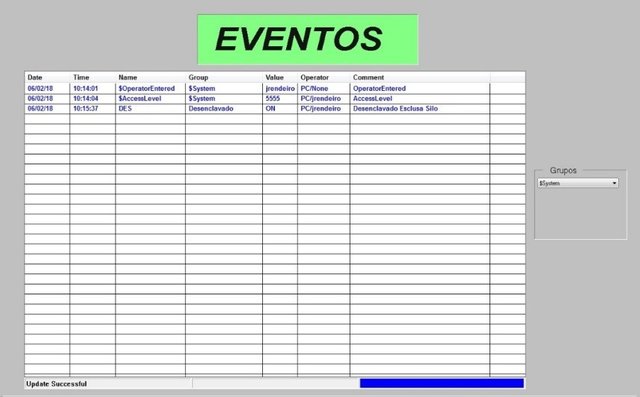

SYSTEM EVENTS

The system has an event registration system where the events associated with the flour dispatch engines were addressed, this event system is composed of warnings that appear once an event occurs. They will be displayed for each event associated with the dispatch engines, whether a motor has not been changed to manual, automatic or unlocked.

The events that occurred will be recorded and will serve as a record to have support for them in case of faults and alarms that are issued.

Congratulations @ebris! You have completed the following achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Do not miss the last post from @steemitboard:

SteemitBoard World Cup Contest - Brazil vs Belgium

Participate in the SteemitBoard World Cup Contest!

Collect World Cup badges and win free SBD

Support the Gold Sponsors of the contest: @good-karma and @lukestokes

Congratulations @ebris! You have completed the following achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard:

SteemitBoard World Cup Contest - Brazil vs Belgium

Participate in the SteemitBoard World Cup Contest!

Collect World Cup badges and win free SBD

Support the Gold Sponsors of the contest: @good-karma and @lukestokes

Great project, thank you. Now automation and upgrade of production, company and business is an important process so that we can move on. It is important not only to have an action plan but also to seek useful cooperation. For example, for industrial motor core lamination stacks that my company needed, I found https://motorneo.com/