3D printing explained, part one

In my recent post i mentioned that i wanted to introduce people to the newer forms of making, going through 3D printing, laser cutting, molding and more.

This is the first post in this series, where i’ll be explaining 3D printing.

3D printing

3D printing is a process by which you can create a physical 3D object from a digital file. It is referred to as an additive process, meaning that the object is created layer by layer, as opposed to subtractive manufacturing, where you cut away from a solid block of material in order to create something. This means that the process of 3d printing can be less wasteful, as you only use the required amount of materials in order to create a product. The process is cheaper than traditional manufacturing, as there is no need for tools and molds. It therefore allows more people to start up a production by themselves. Furthermore, it allows for much more complex shapes. As the process is additive, there is no price difference between complex and non complex objects, as opposed to traditional manufacturing, where complexity means more money spent on tooling, if the object is even possible.

There are however some cons. As of now, 3d printed objects does not yet have the strength of more traditionally created objects. Furthermore, it is rarely suitable for larger production runs, as each item takes a rather long time to produce. Therefore the process is most suitable for prototyping, or for unique items such as art pieces, objects designed for specific purposes, and bits and pieces meant for repairs. If the pricepoint is right, a 3d printer can therefore be a useful addition to any household.

The common 3d printer

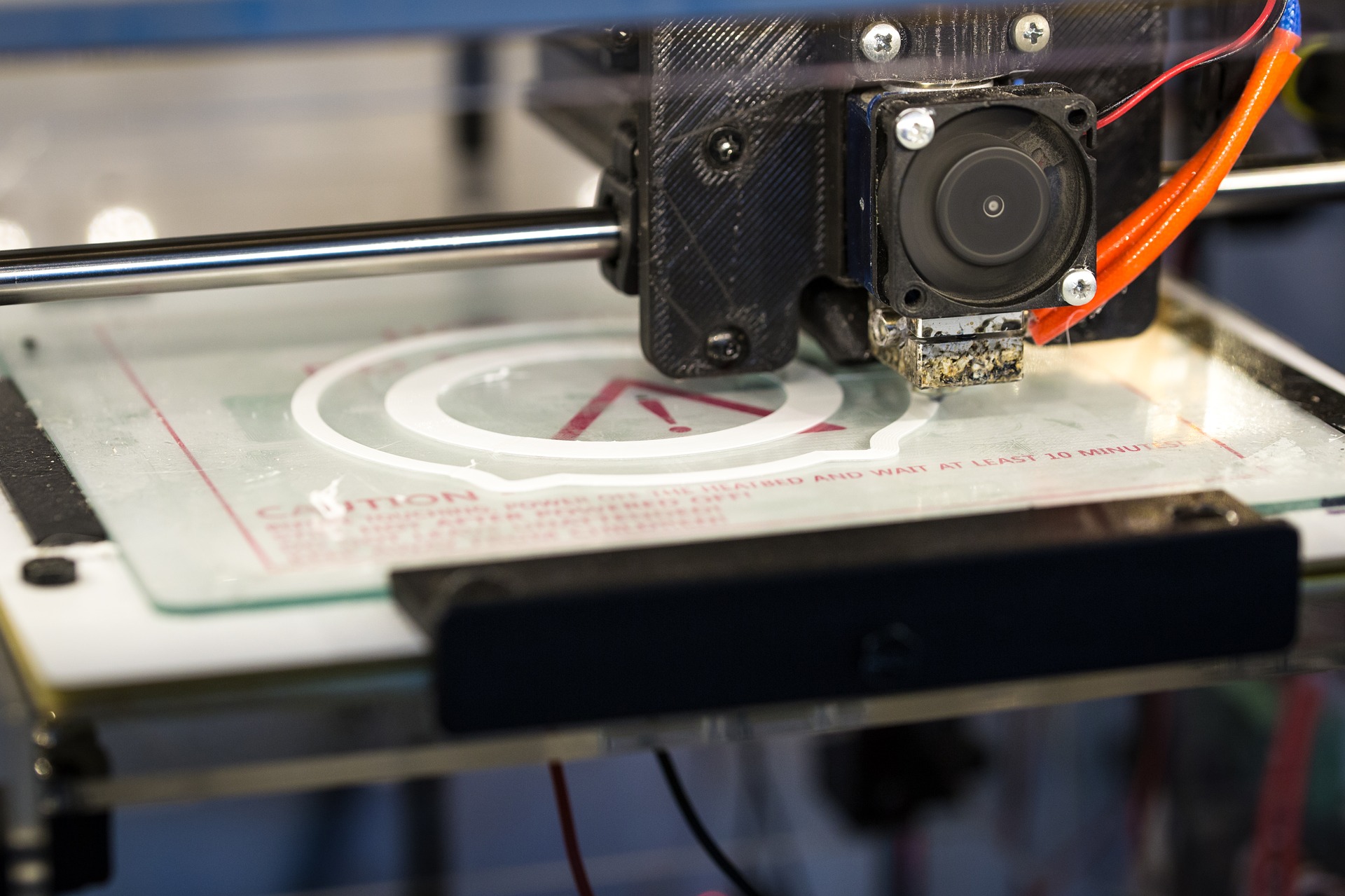

The most common 3D printer in use today is the FDM printer, which stands for Fused deposition modeling. Like other types of 3D printing this was, until recently, limited to industrial use. However, when the patent expired in 2009, we saw the birth of open source projects such as rep rap, which became the stepping stone for many of the more popular 3D printer we see today (3dhub). FDM printers work by depositing a line of melted plastic on a given position. Typically, a string of plastic is fed into a heated nozzle which thereby melts the plastic, placing it on a platform.

Normally you then move the heated nozzle in the x and y position, while you move the platform up and down, on the z position. This allows for drawing a cross section of the object, slowly building it layer by layer. The finished object consists of the object itself, and support material. The support material is sorta like scaffolding, which the printer uses to create the object. As the printer uses melted plastic, it cannot deposit plastic in open air, as the object would otherwise start to hang and droop. Therefore the printer can choose to fill open pockets of air in your object with a brittle, easy to break away material, the support.

Once the object is finished, any support filament is removed, and you can either take it in use, or post process (sanding, painting etc.) for a more refined product.

So how to gain access to a printer?

When it comes to choosing a 3D printer, it really is hard to say, as a lot of factors plays in. Depending on whether you want to build it yourself, your price point and your needs, the choices vary greatly. Maybe you don’t even want a printer yourself, which is certainly a fair point, as the technology is still developing. I will however add a few pointers i myself would look for when buying a new 3D printer

Do you need one?

First of all, do you actually need a 3D printer? Even though you have seen a guy printing a rubber band gun on youtube, or maybe even a baby pikachu which you just gotta have,, you might not necessarily need your own 3D printer. If you only need to print a single item, there’s a wide range of services and places available that can do it for you.

First of all, you should check out https://www.3dhubs.com/ . It is essentially the AirBNB or the uber of manufacturing services, where private people and organisations can offer up their services. Then you can simply find the nearest hub, and pick it up for the given price. If there’s any hub nearby, this is usually pretty convenient.

The other site i would reccomend is https://www.shapeways.com/ which offer high quality prints, in a wide range of materials. They have over 50 materials, including different metals, ceramics, and flexible materials. If you want to, you can even sell your designs on the site.

Lastly, you could go looking for a local place. A lot of cities these days have a local fablab (fabrication lab), and it is more than likely that it will have some people more than willing to help. Here you can find a map where you can check for a nearby lab https://www.fablabs.io/labs/map.

Otherwise you could check out your local library, school or university, which will often have one available.

If you want one

If you do decide to buy your own 3D printer you need to consider some stuff. There’s a lot of important stuff to go through, and i do not have enough room to go through all, but some of the most important aspects are the required size and quality of the print, and whether the printer is open source or not. The answer the last point, i would always go for an open source printer, as to not be limited in my choices. Otherwise you risk being limited by restricted software, and a limited choice of material.

Right now i feel like the market is moving too fast in order to recommend any specific printer, but if you keep those factors in mind, you have a nice starting point. I have personally been happy with the printers i have used from craftunique (https://craftunique.com/item/craftbot-plus-anthracite-gray) and ultimaker (https://ultimaker.com/), but please do your own research. I realize that i didn't get to explain as much as i wanted in this post, but i'll cut it off here, as it is getting quite lengthy. In future posts, i will explain how to actually use a 3D printer, choosing the material, and so on.

If you have made it this far, i applaud you. Thanks a ton.

I hope you're all comfy and safe.

Cheers

I was in a robotics group and we ended up 3d printing things like gears and rollers and stuff. While they did take a long time to print, using the high quality mode allowed for the final product to be a lot stronger as it was more focused on building proper internal support but I mean for high school robotics, strength isn't really an issue.

I like the post though emilclaudell, I wish I personally knew how to make the models for the printers but yeah.

What kind of robots did you make? That sounds awesome? And yeah, it's true, with quality comes strength. And if you're aware of the direction it is printed in, you can make some pretty solid prints.

I'm planning on making a post about 3D modelling, so that will come :)

Sorry about the late response. They were for First Tech Challenge and First Robotics Competition (not battle bots) but we did printings for the smaller robots using 12V 15W DC motors kind of thing. So they weren't exactly powerful or big (they had to fit in a 45cm cube I do believe) and then the other robot was big and yeah, didn't have printed parts

I used to LOVE battle bots. Was so excited when they brought it back :D

But i think i know what you're talking about. Where they only meant to drive around, or should they compete a certain task? (like moving a ping pong ball from point A to B)

Kind of, they had to operate autonomously for part of it and be controlled for part of it. Its the nerds version of sports, but yeah its relatively simple tasks (but lots of scholarships)

Very nice write up! Makes me want to set up mine again to print whatever haha

Please do, i want to see what you can do! :D If you can find it, that is ;)

I think it's at my brothers's... I'll make tomorrow's post about one of the things i made