the future of printing whatever you want; you could print your line of shoes

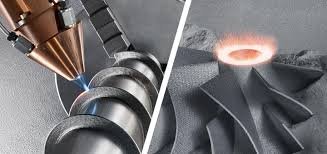

Additive manufacturing

Additive manufacturing is the future of design and engineering . the process of creating near-net shape components layer by layer using 3D model data. An advancement of 3D printing, imagine a world where anyone could make almost anything they need, anywhere.

What if all it took to set up an advanced manufacturing facility was electricity, access to some raw materials, and a computer? an entrepreneur could start selling a new product without ever needing to buy a machine, purchase a tool or prove out a mold; and could start shipping products the day after the design is finalized.

For the aerospace industry this could lead to a reduction of required raw materials used to fabricate an in-service component, which is known as the “buy-to-fly” ratio. AM could also lead to new innovations for lightweight structures that could see application in unmanned aerial vehicles. For the medical industry, AM is already leading to a revolution in customized medicine where dental implants, orthopedics, and hearing aids are manufactured to fit an

individual’s unique physiology.

The most exciting possibilities for AM are for unique applications that could not be fabricated using standard machining practices. Examples include tailored medical implants that can be built with the exact bodily geometry output using an MRI or advanced turbine blades with application specific cooling channel designs. As a fundamentally enabling technology, novel applications that are just beginning to be imagined could be built. Novel functionally gradient materials could be generated using these techniques that could enable entirely new applications.

(photo credit lynda.com, corrosionmaterials.com, trumf.com)

However, there are a limited number of technologies commercially available and there is a great deal of work to be done on ruggedizing these processes for commercial scale manufacturing. In particular, the larger-scale free form fabrication technologies, though their fundamental technologies are commercially deployed in many industries, are at a lower stage of manufacturing readiness as compared to the powder bed or powder injected laser approaches when it comes to AM part production. Closed loop feedback control sensing systems and intelligent feed forward schemes will need to be developed and integrated into systems to better control the manufacturing cycle.(Hendrick 2011)