What is rolling mill and Its Process?

A rolling mill is a machine or plant used to roll metal into plates, bars or other forms. It is an integral part of the metal manufacturing process and is widely used in the steel industry. The main function of a rolling mill is to reduce the thickness of metal by applying compression force through the rolls.

Different types of rolling mills

Two-roll mill: It consists of two opposing rolls between which the workpiece passes.

Three-roll mill: It has three rolls and the workpiece passes in one direction and then in the opposite direction.

Four-roll mill: It contains two smaller working rolls and two larger support rolls.

Multi-roll mill: It consists of support rolls on multiple smaller rolls.

Continuous mill: It is used for large-scale production and consists of a series of rolling mill stands.

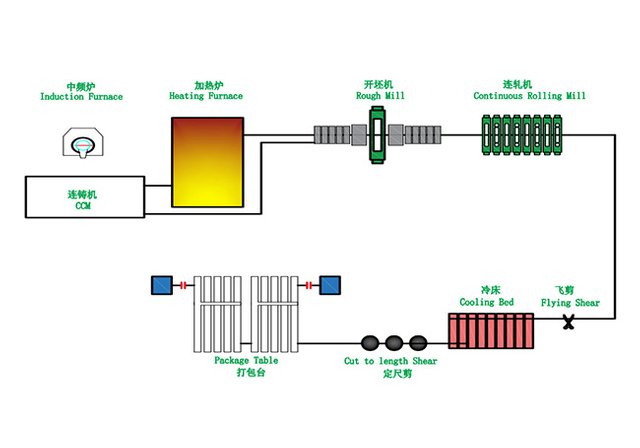

Process flow of rolling mills

The rolling mill process includes the following steps to transform raw metal into finished products:

Heating: The metal is heated to a high temperature to increase ductility.

Rolling: The thickness of the metal is reduced by the rolls.

Reverse rolling: In some rolling mills, the metal passes back and forth through the same set of rollers to achieve the desired thickness and properties.

Cooling: Cooling the metal after it has been rolled to the desired thickness.

Finishing: Processes such as trimming, cutting, or coating are performed depending on the intended use of the metal.

Applications of rolling mills

Rolling mills are used in a wide range of industries, including:

Steel production: Produces plates, bars, rods, etc.

Aluminum production: Rolls aluminum into plates and foils.

Copper production: Rolls copper for electrical applications.

Automotive: Produces metal parts for cars and trucks.

Construction: Manufactures structural steel components for buildings and infrastructure.

Advantages and challenges of rolling mills

Advantages: Efficiency, precision, versatility.

Challenges: High cost, high energy consumption, material defects.

Overall, rolling mills play an important role in modern manufacturing, producing a variety of metal products with high efficiency and precision.

A rolling mill, also known as a steel mill, is a vital piece of equipment in the metal processing industry. It is mainly used to process metal materials (such as steel billets, aluminum, etc.) into desired shapes and sizes, such as plates, strips, wires, pipes, etc., through pressure. The following is a detailed explanation of a rolling mill and its processing process:

Definition of a rolling mill

A rolling mill is a piece of equipment or plant that uses rollers to continuously extrude and deform metal to obtain the desired shape and size. Depending on the processing method and purpose, rolling mills can be divided into hot rolling mills, cold rolling mills, wire rolling mills, profile rolling mills, and other types.

Processing of a rolling mill

The processing of a rolling mill includes multiple steps such as raw material preparation, heating (only for hot rolling), rolling, cooling (as needed), finishing, and inspection.

The raw materials need to undergo pre-treatment work, such as cutting, cleaning, degreasing, and rust removal, to ensure that their surface is clean and defect-free. For the hot rolling process, the raw materials need to be heated before entering the rolling mill to increase their plasticity and reduce their resistance to deformation.

The rolled products may also need finishing treatments, such as straightening, shearing, bundling, etc., to further improve the shape and dimensional accuracy of the products and facilitate subsequent transportation and use. Finally, the rolled products are quality inspected to ensure that they meet relevant standards and customer requirements.

Application fields of steel rolling mills

Steel rolling mills are widely used in many fields such as steel, non-ferrous metals, machinery, construction, automobiles, ships, aerospace, etc. With the continuous development of industrial technology, the processing capacity and processing accuracy of steel rolling mills are also constantly improving, providing more high-quality and efficient metal processing solutions for all walks of life.

In summary, a steel rolling mill is an important metal processing equipment or factory, and its processing process involves multiple links. By continuously optimizing and improving technology and processes, the processing efficiency and product quality of steel rolling mills can be further improved to meet the diversified needs of all walks of life for metal materials.

Related questions

What is the rolling mill process?

What is the process of a roller mill?

What is the process of rolling machine?

What is the roller mill method?